Siruba ASP-PTA100 Original Instructions Manual

- タイプ

- Original Instructions Manual

ASP-PTA100

使用說明書與零件圖

ORIGINAL INSTRUCTIONS BOOK & PARTS LIST

警告圖案表示

INDICATED THE ALERT

PICTORIAL MARKINGS

高壓部位

HIGH-VOLTAGE POSITION

務必關閉電源 10 分鐘後始打開電控

箱蓋子

Be sure to turn off the power and wait

till 10 minutes before opening the

control box´

s

cover.

高速運動部位

HIGH SPEED MOTION

POSITION

謹防工傷事故

In case of industrial accident

高速運動部位

HIGH SPEED MOTION

POSITION

謹防工傷事故

In case of industrial accident

高速運動部位

HIGH SPEED MOTION

POSITION

謹防工傷事故

In case of industrial accident

ii

安全注意事項

SAFETY PRECAUTION

1. 機器在運轉與開關機時,請勿進入該區域

內。

2. 為了保修,檢修卸掉罩蓋時,必須將電源切

到 OFF。

1. When machine is in process, do not enter

working space.

2. When in maintenance, make sure turn off the

power before inspecting and removing the

cover.

電源開關

Power switch

機器動作範圍 ( 區域 ) Machine working space (region)

iii

Introduction

3. 在有危及人體的高壓電處,貼有觸電危險警

告標記。在貼有本警告的電器控制部位而需

要保修、檢修時,打開罩蓋僅能由專業的電

氣技術人員進行。

3.In working place with high voltage power,

there is warning sign. When maintaining

machine control part with this warning, open

the cover and only process by professional

electrical engineer.

4. 機器運轉時,有必要馬上停止機器的時候,

可以按下緊急停止開關。

4. When we need to stop machine in process,

we can press emergent stop button.

5. 電源線、氣壓管線需確實固定安置,不可散

落在地面,以免人

員絆倒而發生危險。

6. 為了生命安全,在任何情況下,不可將電源

地線拔掉運轉機器。

7. 打雷時,為了安全要停止作業, 切斷電源。

8. 離開機器工作地點時或工作結束後一定要將

電源開關轉到 OFF。

9. 機器運轉下,不可卸下罩蓋類。

5. Settle down power line and air line certainly.

Tools should not spread on the floor or

stumble workers in danger.

6. For the safety of life, do not disconnect

ground wire in any situation when

processing machine.

7. When in thunder, cut off power to stop the

process for safety.

8. Must t

urn OFF the power when leaving

working place or finishing working.

9. When processing machine, do not remove

the cover.

緊急停止開關

( 電源 OFF)

Emergent stop button

(power OFF)

iv

索引

INDEX

頁 /PAGE

規格 SPECIFICATIONS 1

安裝 INSTALLATION 2

運轉準備 OPERATION PREPARATION 3

操作面板與啟動開關 OPERATION SWITCH 4

車頭參數設定 MACHINE HEAD CONFIGURATION SETTING 5

紙卡安裝與對位 LABEL INSTALLATION AND ALIGNMENT 6

錯誤代碼 ERROR CODE 11

異常排除 TROUBLE SHOOTING 12

動作模式 MODE SELECT 20

按鍵說明 BUTTON INSTRUCTIONS 23

操作說明 OPERATION INSTRUCTION 24

參數說明 PARAMETER INSTRUCTION 27

故障排除 TROUBLE SHOOTING 31

控制板 ( 一 ) CONTROL BOARD (I) 32

控制板 ( 二 ) CONTROL BOARD (II) 33

I/O 板 I/O BOARD 34

出現錯誤代

碼 E01:

通訊故障

ERROR CODE E01: COMMUNICATION ERROR 36

簡易維修流程圖 SIMPLE MAINTENANCE 36

零件圖 PART LIST 38

氣壓流程圖 AIR PRESSURE DIAGRAM 52

氣壓裝配圖 AIR PRESSURE ASSEMBLY DIAGRAM 53

路線總圖 CIRCUIT DIAGRAM 54

v

Introduction

規格

SPECIFICATIONS

型號 Model ASP-PTA100

搭配縫紉機機頭

Collocation Machine Head

平縫(高速電子套結機)

lockstitch (high speed electrical bartacking

machine)

車縫速度 Sewing speed 最高 Max 2000 SPM

使用針型 Needle Type DP×17 #11

紙卡單邊長 Label Length 35~65mm

紙卡寬度 Label Width 35~65mm

摺痕寬度 Crease Width 5~6mm

紙卡厚度 Label Thickness 0.4~0.6mm

車縫範圍 Sewing range 水平 3~6mm ( 最大 ) X axis 3~6mm

氣體消耗量 Air consumption 2L/min

氣壓 Air Pressure 0.5 Mpa

電源電壓 Voltage

單相 AC200~240V 50/60Hz

Single Phase

AC200~240V 50/60Hz

消費電力 Voltage consumption 1150VA(最大 Max)

機器尺寸 Dimensions

寬 1050× 深 750× 高 1530mm ( 含桌板、線架 )

(W)1050×(D)750×(H)1530mm ( With table

and thread stand )

適用紙卡規格

Applicable label dimension

P1

摺痕寬 Crease width

摺縫中心線

Label crease center

5~6mm

35~65mm

35~65mm 35~65mm

桌板①上,鎖付線架②。

( 線架組裝組請參照 LKS-1903AN 使用說明書 。)

Install thread rack ② on the table ①.

(Ref LKS-1903AN user manual.)

安裝

INSTALLATION

②

①

線架

Thread rack

P2

Introduction

1. 電源電壓

A. 單相 AC200~240V 50/60Hz ±10%。

B. 接地線一定要接地。

2. 氣壓

A. 使用 0.5 Mpa(5kg/c㎡ )。

3. 供油

A. 縫紉機頭部

請參照 LKS-1903AN 使用說明書。

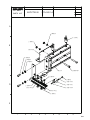

4. 設定紙卡尺寸及補料

鬆開快速把手①後調整滑塊②至紙卡規格對

應尺寸,再將料卡放置於載料平台。

1.Voltage

A. Single Phase AC200~240V 50/60Hz ±10%

B. Ground wire must connect.

2.Air pressure

A. Use 0.5 Mpa(5kg/c㎡ )。

3.Feed oil

A. Machine head

Ref LKS-1903AN user manual.

4. Set label dimension and fill the material

After loosing quick spancer

① , adjust sliding

block ② to satisfy label dimension and then

put label material on material platform.

運轉準備

OPERATION PREPARATION

P3

1. 操作面板 1. Operation panel

操作面板與啟動開關

OPERATION SWITCH

準備鍵

Ready button

SIRUBA

LKS-1903AN

操作面板

Operation panel

P4

Introduction

啟動開關

Activation switch

壓腳開關

Switch for presser foot

1

直接啟動車縫模式

Directly sewing mode

踩踏啟動開關時,壓腳自動下壓就直接車縫

When activation switch, lowering presser foot automatically, then

directly start sewing

2

兩段式車縫模式

2-step sewing mode

單踩壓腳開關時,可使壓腳下壓或抬升用於車縫對位,壓腳必須處

於下壓狀態,踩踏啟動開關才有作用,壓腳未下壓則無法啟動車縫

動作

We could merely tread switch for presser foot to lower or to raise

presser foot to align sewing position. Users should lower presser

foot and then activation switch will work. If

not, users could not

start sewing.

啟動車縫有兩種模式: Two modes to enable sewing:

※ 模式選擇請參閱人機介面使用說明 ※Please refer to instruction book of human

machine interface for mode selection

2. 腳踏開關 2. Knee pedal switches

車頭參數設定

MACHINE HEAD

CONFIGURATION SETTING

1. 按下電源 ON 開關,按住 鍵約 6 秒進

入設定模式。

2. 按

、 鍵選擇參數。

3. 找到要變更的參數,按

鍵,進入修

改模式,按

、 鍵來變更內容,

更改完後,再按一次

鍵跳出修改模

式。

4. 所有參數都修改完後按

鍵跳出設定模

式。

5. 修改的參數內容如下

1.Press power on switch hold

about 6

seconds to enter setting mode.

2.Press

、 button to select figures.

3.Select the figures. Press

button enter

adjusting mode. Press

、 to

change content. After adjustment, press

to exit adjusting mode setting value.

4.Press

button to exit setting mode.

5.Refer below for configuration figurces.

順序 Sequence 參數編號 Configuration No. 設定值 Setting value

1 241 9

2 19 2

3 20 1

4 24 0

5 37 1

6 51 1

7 62 1

P5

紙卡安裝與對位

LABEL INSTALLATION AND ALIGNMENT

1. 紙卡尺寸變更時

依紙卡摺痕中心至左及右邊的長度來調整

滑塊對應的刻度,寬度亦是如此。

2. 紙卡摺痕偏移調整

若紙卡摺痕偏離夾具位置時,需微量調整紙

卡安裝位置以符合夾持位置。

1.When label dimension changes

According to label crease center, adjust

length between left border and right border

and then adjust width by the same way.

2.Adjust the deviation of label crease

If label crease deviates from the clamp

position, fine tune the installation posit

ion of

label to fit clamp position.

P6

Introduction

紙卡

Label

摺痕

Crease

紙卡摺痕中心

Label crease center

夾具

Clamp

微調紙卡長度位置即可將摺痕偏移至夾具位

置。

Fine-tune label length position to move the

crease deviation to the clamp position

3. 縫線位置調整

紙卡中心偏左或偏右時,將造成縫線不在卡

片正中心位置上。

3. Adjust sewing position

When label deviate left or right from center,

sewing line will not be in the middle of label.

P7

卡片中心線

Label center

縫紉中心

Sewing center

微調卡片寬度位置與限位塊即可改變縫線偏

左或偏右的問題。

Fine-tune label width position and limiting

block to solve the problem that sewing line

deviates left or right.

P8

Introduction

中心線對準

Align center line

限位塊

Limiting block

調整擋邊氣缸固定座可決定紙卡縫線前後的

位置。

Adjust guide block cylinder seat to set label

sewing line position.

P9

擋邊氣缸固定座

Guide block cylinder seat

螺絲鬆開後調整

Adjust after loosing screws

限位銷可限制紙卡左右些許的偏差範圍,當

卡片寬度變更時需調整至紙卡邊界。

Limited pin could limit the deviation of the

label. When label width changes, limited pin

needs to adjust to the label boundary.

限位銷與紙卡邊界需留間隙約 0.5 ~ 1mm,

如此紙卡才不會被撞歪。

Need to keep 0.5~1 mm space for limited pin

and label. Then label will not crash.

P10

Introduction

螺絲鬆開可調整位置

Loose screw to adjust

the position

螺絲鬆開可調整位置

Loose screw to adjust the position

限位銷

Limited pin

保留間隙

Keep space

限位銷

Limited pin

保留間隙

Keep space

紙卡邊界

Label boundary

紙卡邊界

Label boundary

錯誤代碼 ERROR CODE

代碼

Code

說明

Description

備註

Memo

E01

通訊異常

Network error

見 4. 故障排除 章節

Ref. by paragraph 4.Trouble shooting

E02

缺料顯示

Show lack of material

待載料平台下降,進行補料後,按下重置鍵

Lower material platform, fill material and press

reset button

E11

運料氣缸未確實處於

準備點 / 原點位置

Cylinder for material transmission

does not stay in standby/original

position well

1 號氣缸 / 準備點微動開關 / 原點磁簧開關異常

No. 1 cylinder/standby point micro switch or

original point re

ed switch error

E12

前伸氣缸未確實縮回

Forward cylinder does not retract well

2 號氣缸 / 磁簧開關異常

No. 2 cylinder/reed switch error

E14

塑形氣缸未確實下降

Forming cylinder does not lower well

4 號氣缸 / 磁簧開關異常

No. 4 cylinder/reed switch error

E16

夾料臂未確實到待命令位置

Clamp does not arrive standby point

well

6 號氣缸 / 磁簧開關異常

No. 6 cylinder/reed switch error

E18

擋邊氣缸未確實退回

Guide block cylinder does not return

well

8 號氣缸 / 磁簧開關異常

No. 8 cylinder/reed swi

tch error

-

若於運料時,運料失敗,導致成型區

感應器未判讀有料,夾爪不會執行前

伸動作

If transmitting material is not well,

sensor on forming part does not detect

material. Clamp will not forward and

catch material

按下 重置鍵 再次進行運料動作

Press reset and feed material again

P11

異常排除

TROUBLE SHOOTING

現象

Description

原因

Reason

對策

Solution

參考頁數

Ref. page

摺痕未對夾具中心

Crease is not in the clamp

middle

1. 紙卡安裝位置偏移。

2. 夾具機構位置錯誤。

1.Label position

deviates

2.Clamp position error

1. 微調料槽長度滑塊位

置。

2. 調整氣缸束環位置。

1.Fine tune length

sliding block position

of material platform

2.Adjust the position of

cylinder limiting ring

P.00~P.00

P.00

縫線未在紙卡正中心

Sewing line is not on the label

middle.

1. 紙卡安裝位置偏移

1.Label position

deviates

微調料槽寬度滑塊位

置及限位塊。

Fine tune position of

width sliding block

and limiting block

P.00~P.00

縫線未在指定位置

Sewing line is not on assigned

location

1. 擋邊氣缸位置錯誤

1.Wrong position of

guide block cylinder

微調擋邊氣缸固定座的

鎖固位置。

Fine tune fixed position

of guide block cylinder

seat

P.00

夾槽無法開啟

Unable to open clamp

slotlocation

1. 疊料造成

1.Materials overlap.

吸盤分料時,調整吹嘴

角度與風量使疊料分

離。

When suction cup

catches material,

adjust the angle of air

nozzle and the strength

of air to separate

material stack.

P.00

P12

Introduction

實際位置

Actual location

實際位置

Actual location

預定位置

Assigned

location

預定位置

Assigned

location

現象

Description

原因

Reason

對策

Solution

參考頁數

Ref. page

成形角度不足

Forming angle is not enough 1. 夾槽選用錯誤。

1. Select wrong clamp

slot

更換適用該紙卡摺痕

寬度的夾槽。

Replace clamp slot

which is suitable for

label crease width.

P.00~P.00

吸盤取料失敗

Failure to catch material by

suction cup

1. 載料平台上升停止

位置過低。

1.Material platform

raises not enough.

微調入料檢知位置。

Fine-tune filling

detection position.

P.00

夾具撞擊夾料區紙卡

Clamp crashes label on forming

part

1. 料卡不平整拱起而

被進

入的夾棒撞歪。

1.Material label is not

flat and arch so it is

crashed by clamping

rod when rod is

entering

料卡拱起程度不可超

過 3mm,需人工整

平。

Material label can not

arch more than 3 mm

or need to smoothen

it by users.

P.00

P13

1. 紙卡疊料

吸盤吸附紙卡兩張以上時,將造成夾具無法

開夾而異常,此時可以調整吹氣嘴的角度與

吹氣量大小來進行疊料排除。(註:紙卡若

因印刷油墨沾黏則需人工排除)

1. Labels overlap

When suction cup catches more than 2 labels,

clamp will not open and error. In this situation,

we can adjust the angle of air nozzle and the

strength of air blow to remove material stack

(note: users will need to remove by hand if

labels stick together by ink or else)

旋轉螺桿可調整吹氣量大小

Able to adjust blowing strength

by rotatory screw rod

需使用 3mm 六角板手伸入氣孔調整吹氣角度

Need to use 3 m m hex wrench to enter air

inlet to adjust the angle of blowing air

氣嘴調整方式

Air nozzle adjustment

氣嘴

Air nozzle

P14

Introduction

2. 成型角度不足

夾具有對應摺痕5mm或6mm寬的夾槽,

當成型角度不足時,會發生進料失敗的情形,

此時需更換正確的夾槽才能順利成形。

2.Incorrect forming angle

Clamp need to match 5mm or 6mm width

clamp slot. When the forming angle is not

enough, feeding process will be error. In such

situation, we need to replace correct clamp

slot to form it correct.

P15

夾角過大

Too large angle

進料失敗

Failure to

feed material

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

Siruba ASP-PTA100 Original Instructions Manual

- タイプ

- Original Instructions Manual

関連論文

-

Siruba ASP-PTA101 Instruction book

-

Siruba LKS-1900AN Instruction book

-

Siruba C007L C007LX Instruction book

-

Siruba D007S Instruction book

-

Siruba ASV-ATS100A Instruction book

-

Siruba 700LQ Instruction book

-

Siruba ASK-ASM200 Instruction book

-

Siruba DL730 取扱説明書

-

Siruba DL7200C 取扱説明書

-

Siruba LF375-FA-LFA-LFR Instruction book

その他のドキュメント

-

Genmitsu 245805502 ユーザーマニュアル

-

DURKOPP ADLER 267 - 2016 取扱説明書

-

DURKOPP ADLER 251-140042 Manual Motor

-

Duerkopp Adler 261_vaild_from_december_2019 取扱説明書

Duerkopp Adler 261_vaild_from_december_2019 取扱説明書

-

DURKOPP ADLER 261_valid_till_november_2019 取扱説明書

-

Creality CR-200B ユーザーマニュアル

-

Husqvarna 525BX ユーザーマニュアル

-

Wacker Neuson PT6LT ユーザーマニュアル

-

Zanussi ZTE171 ユーザーマニュアル

-

Electrolux EDI97170W ユーザーマニュアル