DURKOPP ADLER 261_valid_till_november_2019 取扱説明書

- カテゴリー

- ミシン

- タイプ

- 取扱説明書

操作说明

Operating Instructions

零件列表

Parts List

261

非常感谢您购买本公司的工业缝纫机。在使用缝纫机之前,请仔细阅读(为了您的安全使用)和使用说明

书。

工业缝纫机的特性之一,是要在机针和旋梭等运动零部件附近进行操作,而这些零部件很容易引起受伤的

危险,所以请在受过培训的人员或有熟练操作技术的人员的指导下,正确地使用本缝纫机。

为了您的安全使用

1.安全使用的标记及其意义

本使用说明书及产品所使用的标记和图案记号是为了您的安全而正确地使用本产品,防止您及他人受到危

害和损害。

表示方法及含义如下:

说明

危险

注意

如果忽视此标记而进行了错误的操作,必将导致人员死亡或重伤。

如果忽视此标记而进行了错误的操作,有可能会引起人员受伤及造成设备损坏。

图案和符号

符号△表示“应注意事项”。

三角中的图案表示必须要注意的内容。

(如左图的符号表示“注意受伤”。)

符号○表示“禁止”。

符号●表示“必须”。

圆圈中的图案表示必须要做的内容。

(如左图的符号表示“必须接地”。)

Ⅰ

警告

如果忽视此标记而进行了错误的操作,将会引起人员重伤或死亡。

Thank you very much for buying our sewing machine.Before using your new machine,please read the safety instructions below

and the explanations given in the Operation Instruction.

With industrial sewing machines,it is normal to carry out work while positioned directly in front of moving parts such as the

needle and thread take-up lever,and consequently there is always a danger of injury that can be caused by these parts.Follow

the instructions from training personnel and instructors regarding safe and correct operation before operating the machine so

that you will know how to use it correctly.

SAFETY INSTRUCTIONS

1.Safety indications and their meanings

This instruction manual and the indications and symbols that are used on the machine itself are provided in order to ensure

safe operation of this machine and to prevent accidents and injury to yourself or other people.

The meaning of these indications and symbols are given below.

Indications

DANGER

CAUTION

The instructions which follow this term indicate situations where failure to follow the

instructions will almost certainly result in death or severe injury.

The instructions which follow this term indicate situations where failure to follow the

instructions could cause injury when using the machine or physical damage to equipment

and surroundings.

Symbols

This symbol (△) indicates something that you should be careful of. The picture inside the

triangle indicates the nature of the caution that must be taken.

(For example, the symbol at left means"beware of injury".)

This symbol (○) indicates something that you must not do.

This symbol (●) indicates something that you must do. The picture inside the circle indicates

the nature of the thing that must be done.

(For example, the symbol at left means "you must make the ground connection".)

Ⅱ

CAUTION

The instructions which follow this term indicate situations where failure to follow the

instructions will almost certainly result in death or severe injury.

2.安全注意事项

危险

打开控制箱盖时,必须先关闭电源开关并将电源插头从插座上拔下,至少等待5分钟后,再打开控

制箱盖。触摸带有高电压的区域将会造成人员伤亡。

注意

使用环境

应避免在强电气干扰源(如高频焊机)的附近使

用缝纫机。

强电气干扰源可能会影响缝纫机的正确操作。

电源电压的波动应该在额定电压的±10%以内

的环境下使用。

电压大幅度的波动会影响缝纫机的正确操作。

电源容量应大于缝纫机的消耗能量。电源容

量不足会影响缝纫机的正确操作。

环境温度应在5℃-35 的范围内使用。

低温或高温会影响缝纫机的正确操作。

℃

缝纫机的最佳工作环境是

85%的范围内,干燥或潮湿的环境均会影响缝

纫机的正确操作。

相对湿度在45%-

使用时应避免暴露于直射的阳光下。

直射的阳光会影响缝纫机的正确操作。

万一发生雷电暴风雨时,关闭电源开关,并将

电源插头从插座上拔下。雷电可能会影响缝纫

机的正确操作。

安装

请让受过培训的技术人员来安装缝纫机。

请委托购买商店或电气专业人员进行电气

配线。

缝纫机重约40公斤,安装工作必须由两人以

上来完成。

在安装完成前,请不要连接电源,如果误

按启动开关,缝纫机动作会导致受伤。

请在切断电源后,再拔掉电源插头。不然易

成为控制箱发生故障的原因。

必须接地。接驳地线不牢固,是造成触电

或误动作的原因。

固定电缆时,不要过度弯曲电缆或用卡钉

固定得过紧,会引起火灾或触电的危险。

如果使用带小脚轮的工作台,则应该固定小

脚轮,使其不能移动。

缝纫机头倒下或竖起时,请用双手进行操

作。单手操作时因缝纫机的重量万一滑落易

导致受伤。

使用润滑油或黄油时,务必戴好保护眼镜和

保护手套等,以防润滑油落入眼中或沾在皮

肤上,这是引起发炎的原因。

另外,润滑油或黄油不能饮用,否则会引起

呕吐和腹泻。

将油放在小孩拿不到的地方。

!

!

!

!

!

!

!

!

!

!

!

!

Ⅲ

请勿将手放入皮带开口处,否则手可能会将被卷入皮带中造成重伤。

DANGER

Wait at least 5 minutes after turning off the power switch and disconnecting the power cord from the wall outlet before

opening the face plate of the control box. Touching areas where high voltages are present can result in severe injury.

CAUTION

Environmental requirements

Use the sewing machine in an area which is free from

sources of strong electrical noise such as high-

frequency welders.

Sources of strong electrical noise may cause

problems with correct operation.

Any fluctuations in the power supply voltages should

be within ±10% of the rated voltage for the machine.

Voltage fluctuations which are greater than this may

cause problems with correct operation.

The power supply capacity should be greater than

the requirements for the sewing machine's electrical

consumption.

Insufficient power supply capacity may cause

problems with correct operation.

In the event of an electrical storm, turn off the power

and disconnect the power cord from the wall outlet.

Lightning may cause problems with correct operation.

The ambient temperature should be within the range

of 5℃ to 35℃ during use.

Temperatures which are lower or higher than this may

cause problems with correct operation.

The relative humidity should be within the range of

45% to 85% during use, and no dew formation should

occur in any devices.

Excessively dry or humid environments and dew

formation may cause problems with correct operation.

Avoid exposure to direct sunlight during use.

Exposure to direct sunlight may cause problems with

correct operation.

Installation

Machine installation should only be carried out

by a qualified technician.

Contact your dealer or a qualified electrician for

any electrical work that may need to be done.

The sewing machine weighs approximately 40kg.

The installation should be carried out by two or

more people.

Don't connect the power cord until installation is

complete, otherwise the machine may operate if

the foot switch is depressed by mistake, which

could result in injury.

Be sure to connect the ground. If the ground

connection is not secure, you run a high risk of

receiving a serious electric shock, and problems

with correct operation may also occur.

Install the safety covers to the machine head and

motor.

Hold the machine head with both hands when tilting

it back or returning it to its original position.

Furthermore, after tilting back the machine head,

do not push the face plate side or the pulley side

from above, as this could cause the machine head

to topple over, which may result in personal injury

or damage to the machine.

All cords should be secured at least 25mm away

from any moving parts. Furthermore, do not

excessively bend the cords or secure them too

firmly with staples, otherwise there is the danger

that fire or electric shocks could occur.

If using a work table which has caster, the

casters should be secured in such a way so that

they cannot move.

Be sure to wear protective goggles and gloves

when handling the lubricating oil and grease, so

that they don't get into your eyes or onto your

skin, otherwise inflammation can result.

Furthermore, do not drink the oil or eat the

grease under any circumstances, as they can

cause vomiting and diarrhoea.

Keep the oil out of the reach children.

! !

!

!

!

!

!

!

!

!

!

!

Ⅳ

Please do not put hand in belt openings, or hand may be involved into the belt will be seriously injured.

2.Notes on safety

注意

缝纫

本缝纫机不能用于除缝纫以外的任何其他用

途。

发生下列情况时,请切断电源。否则误按动启

动开关,缝纫机动作会导致受伤。

·机针穿线时

·更换机针或梭芯时

·缝纫机不使用,或人离开缝纫机时

如果使用带小脚轮的工作台,则应该固定小

脚轮,使其不能移动。

为了安全起见,在使用本缝纫机之前,请安装

保护装置。如果未安装这些安全装置就使用缝

纫机,会造成人身伤害及缝纫机损坏。

缝纫过程中不要触摸任何活动部件或将物件靠

在运动部件上,因为这会导致受伤或缝纫机损

坏。

如果缝纫机出现故障时,请与购买商店或受过

培训的技术人员联系。

如果缝纫机操作中发生误动作,或者听到异常

的噪声或闻到异常的气味,应立即切断电源。

然后与购买商店或受过培训的技术人员联系。

清洁

在开始清洁作业前,请切断电源。如果误

踩了脚开关,缝纫机动作会导致人员受

伤。

使用润滑油或黄油时,务必戴好保护眼镜

和保护手套等,以防润滑油落入眼中或沾

在皮肤上,这是引起发炎的原因,

另外,润滑油或黄油不能饮用,否则会引

起呕吐和腹泻。

将油放在小孩拿不到的地方。

本缝纫机仅限于接受过安全操作培训的人员使

用。

!

!

!

2.安全注意事项

Ⅴ

CAUTION

Sewing

This sewing machine should only be used by

operators who have received the necessary training

in safe use beforehand.

The sewing machine should not be used for any

applications other than sewing.

Be sure to wear protective goggles when using the

machine.

If goggles are not worn, there is the danger that if a

needle breaks, parts of the broken needle may

enter your eyes and injury may result.

If an error occurs in machine operation, or if

abnormal noises or smells are noticed, immediately

turn off the power switch. Then contact your nearest

dealer or a qualified technician.

If using a work table which has casters, the casters

should be secured in such a way so that they cannot

move.

Attach all safety devices before using the sewing

machine. If the machine is used without these

devices attached, injury may result.

Do not touch any of the moving parts or press any

objects against the machine while sewing as this may

result in personal injury or damage to the machine.

Cleaning

Turn off the power switch before carrying out

cleaning, otherwise the machine may operate if

the foot switch is depressed by mistake, which

could result in injury.

Be sure to wear protective goggles and gloves

when handing the lubricating oil and grease, so

that they do not get into your eyes or onto your

skin, otherwise inflammation can result.

Furthermore, do not drink the oil or eat the grease

under any circumstances, as they can cause

vomiting and diarrhoea.

Keep the oil out of the reach of children.

Turn off the power switch at the following times,

otherwise the machine may operate if the foot switch

is depressed by mistake, which could result in injury.

·When threading the needle

·When replacing the needle and bobbin

·When not using the machine and when leaving the

machine unattended

If the machine develops a problem, contact your

nearest dealer or a qualified technician.

!

!

!

!

Ⅵ

2.Notes on safety

Ⅶ

2

4

4

4

5

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

15

9.膝动提升高度的调整

10.踏板操作

11

.线张力的调整

12.挑线弹簧

13.压脚提升

14.压脚压力的调节

15.送布相位的调节

16.送布牙的倾斜

17.送布牙的高度

18.机针与旋梭的关系

19.压脚高度的调节

20.定刀与移动刀的转换 Change of fixed knife and shift knife

21.挑线杆挑线量的调节

22.踏板压力和行程

23.踏板的调整

24.手触动倒缝

25.脚踏板的连接 Foot switch connection

26.规格

27.常见故障与调整

$+($&6HUYR6\VWHP+0,8VHU0DQXDO

$+(ᮦӚ⍷հᵃ㌱㔕+0,ֵ⭞䈪᱄Ҝ

.....

.

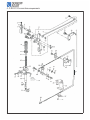

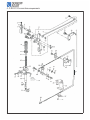

(1).油盘的安装

Installing the oil pan

1) 油盘应搁在工作台凹槽四角。

2) 如图所示,先将两只油盘支座小①与两只油盘支

座大②分别置于油盘的四角,然后将油盘③与油盘

支座按如图所示方向放置于台板上.

1) The oil pan should rest on the four corners of the machine

table groove.

2)Fix two rubber seats ① and two rubber seats ②on the four

corners of the oil pan.The oil pan should rest on the machine

table groove.

(2).铰链的安装

将机头连接钩①放入底板孔内,与台板的机头连接钩

座②相嵌合,再将机头放到四只角的机头支座③上.

Fit hinge① into the opening in the machine bed,and fit the

machine head to table rubber hinge ② before placing the

machine head on cushions ③ on the four corners.

Installing the hinge

使用说明书

OperatinJ InstructionV

1.缝纫机的安装 Installation

1

2.加油

Lubrication

1)把专用10#缝纫机润滑油加入到油盘①,加到HIGH

标记A的位置。

2)如果油面降到LOW标记B以下时,请再次把油加至

HIGH位置。

3)加油后运转缝纫机,润滑正常时应能看到油窗②

里油面跳转。

4)油跳动量的大小与油量的多少无关,因此不用担

心。

(注意)新缝纫机或较长时间没有使用的缝纫机,应

进行约10分钟每分3000针的磨合运转。

1) Fill oil pan ① with New Special Oil up to HIGH mark.

2) When the oil level lowers below LOW mark, refill the oil

pan with the specified oil.

3)When you operate the machine after lubrication, you will

see splashing oil through oil sight window ② if the

lubrication is adequate.

4) Note that the amount of the splashing oil is unrelated to

the amount of the lubricating oil.

(Caution) When you first operate your machine after setup

or after an extended period of disuse, run your machine at

3000 s.p.m. to 35000 s.p.m. for about 10 minutes for the

purpose of break-in.

使用说明书

2SHUDWLQJ,QVWUXFWLRQV

A

B

(1).旋梭油量调整

1) 把下轴前段部的油量调节螺丝向+方向(A方向),转动

油量增多,向-方向(B方向)转动油量变少。

2) 油量调节螺丝调节后,请进行30秒钟的空运转,以确

认油量。

1) Turning the oil amount adjustment screw attached on the

hook driving shaft front bushing in the + direction(in direction

A) will increase the amount of oil in the hook, or in the “-“

direction(in direction B) will decrease it.

2) After the amount of oil in the hook has been properly

adjusted with the oil amount adjustment screw, make the

sewing machine run idle for approximately 30 seconds to

check the amount of oil (oil splashes) in the hook.

Adjusting the amount of oil in the hook

3.油量的调节 Adjusting the amount of oil

2

进行下列2的作业时,请卸下推板,同时要充分注意

手指不要碰到旋梭。

1) 机头冷却时,请进行3分钟左右的空载运转。(适

当的间歇运转)

2) 请在缝纫机转到时将油量确认专用纸插入。

3) 请确认油盘的油面高度是否在HIGH和LOW范围之

内。

4) 油量确认时间为5秒钟。(用表来测定)

When carrying out the procedure described below in 2,

remove the slide plate and take extreme caution not to allow

your fingers to come in contact with the hook.

(Caution)

1) If the machine has not been sufficiently warmed up for

operation, make the machine run idle for appro ximately

three minutes.(Moderate inter mitten operation.)

2) Place the amount of oil (oil splashes) confirm mation

paper under the hook while the sewing machine is in

operation.

3) Confirm that the height of the oil surface in the oil

reservoir is within the range between “HIGH” and “LOW”.

4) Confirmation of the amount of oil should be completed in

five seconds.(Check the period of time with a watch.)

注意

旋梭以调整运转。为了防止人身伤害,请充分注意调节油量。

CAUTION

Be extremely careful about the operation of the machine since the amount of oil has to be checked by

turning the hook at a high speed.

①油量确认专用纸

①Amount of oil confirmation paper

·不用考虑纸的质量

·Use any paper available regardless of the material

②油量确认位置

②

Position to confirm the amount of oil

·把油量确认专用纸插到旋梭下面。

·Place the amount of oil (oil splashes) confirmation

paper under the hook.

3~10mm

旋梭

Hook

下轴前端

Hook driving shaft front bushing

底板

Bed

油确认专用纸

Oil splasbes confirmation paper

油盘

Oil reservoir

顶到油盘的壁面

Closely fit the paper

against the wall

surface of the oil

reservoir

25mm左右

Approx.25mm

70mm左右

Approx.70mm

使用说明书

2SHUDWLQJ,QVWUXFWLRQV

(2).油量的确认 Confirm the amount of oil

5) 左图样品根据缝制工序需要微调增减,但注意不要过

大增加或减少。

(油量过少时,会烧坏旋梭(发热)。油量过多时,会玷污

缝制品)

6) 油量应确认3次(3张)均无变化。

5) The amount of oil shown in the semples on the left

should be finely adjusted in accordance with sewing

processes. Be careful not to excessively increase/decrease

the amount of oil in the hook. (If the amount of oil is too

small, the hook will be seized (be hook will be hot). If the

amount of oil is too much, the sewing product may be

stained with oil.)

6) Adjust the amount of oil in the hook so that the oil

amount should not change while checking the oil amount

three times (on the three sheets of paper).

从旋梭飞溅出来的油

Splashes of oil from the hook

1mm

左右

油量偏(小)

Appropriate amount of oil(small)

从旋梭飞溅出来的油

Splashes of oil from the hook

3mm

左右

油量偏(大)

Appropriate amount of oil(large)

③适合的油量样品

③

Sample showing the appropriate amount of oil

3

1) 手拿梭心,让线往左绕 方向,把它放入梭壳。

2) 把线穿过梭壳的穿线口A,然后把线往B方向拉,

从线张力弹簧下面的穿线口B拉出来。

3) 拉底线C,确认梭心是否按箭头方向转动。

C

5.梭心的安装方法

Setting the bobbin into the bobbin case

1) Install the bobbin in the bobbin case so that the thread

wound direction is clock wise.

2) Pass the thread through thread slit , and pull the thread

in direction . By so doing, the thread will pass under the

tension spring and come out from notch .

3) Check that the bobbin rotates in the direction of the

arrow when thread is pulled.

请根据线的粗细、布料的种类选择适当的机针。

1) 转动手轮,把针杆升到最高处。

2) 拧松机针固定螺丝

②,手拿机针把机针①凹部A

横向转到B的方向。

3) 把机针插到针杆孔的深处。

4) 拧紧机针固定螺丝

②。

5) 确认针的长孔C在左横向D的方向。

4.机针的安装方法

Attaching the needle

Select a proper needle size according to the count of thread

and the type of material used.

1) Turn the handwheel until the needle bar reaches the

highest point of its stroke.

2) Loosen screw ②, and hold needle ① with its indented

part A facing exactly to the right in direction B.

3) Insert the needle fully into the hole in the needle bar in

the direction of the arrow until the end of hole is reached.

4) Securely tighten screw ②.

5) Check that long groove C of the needle is facing exactly

to the left in direction D.

使用说明书

2SHUDWLQJ,QVWUXFWLRQV

6.上线穿线方法

Threading the machine head

注意

为了防止意外的启动造成的事故,请关掉电源后进行。

CAUTION

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

4

7.缝迹长度的调节

Adjusting the stitch length

8.线架的安装

1)如图所示把线架安装到台板右上角孔上。

2)用固定螺母①固定线架。

3)若采用顶线配线时,请把电源线从线架杆②中

穿过。

1)Assemble the thread stand unit, and insert it in the hole

in the machine table.

2)Tighten locknut ① to fix the thread stand.

3)For ceiling wiring, pass the power cord through spool

rest rod ②.

Installing the thread stand

1) 按下锁针距压板 沿箭头方向转动送料距旋钮 ,

并把希望的数字对准锁针距压板

PUSH下面的刻线。

2) 刻度盘的数字单位为mm。

3) 从大往小变更送布刻度时,请

同时转动送料距旋钮①进行调节。

① ②

①按下锁针距压板

1)Press lock stitch plate ① turn stitch length dial button ② in

the direction of the arrow ,and align the desired number to

marker line on lock stitch plate.

2)The dial calibration is in millimeters.

3)When you want to decrease the stitch length, press lock

stitch plate ① while turn stitch length dial button ①.

使用说明书

2SHUDWLQJ,QVWUXFWLRQV

9.膝动提升高度的调整

Adjusting the height of the knee lifter

1) 膝动提升压脚的标准高度为10mm。

2) 调节膝动提升调节螺丝①可以把压脚最高提升

到13mm。(薄料机种最大只能调到9mm)

3) 压脚提升到10mm以上时,调整时请注意不要让

针杆②的前端在最下方时也不能碰到压脚③。

1) The standard height of the presser foot lifted using the

knee lifter is 10mm.

2) You can adjust the presser foot lift up to 13 mm using

knee lifter adjust screw ①. (The max, lift should be 9 mm

for the weak material)

3) When you have adjusted the presser foot lift to over 10

mm, be sure that the bottom end of needle bar ② in its

lowest position does not hit presser foot ③.

5

10.踏板操作

1.踏板有4级操作。

1) 向前轻轻踩踏板为低速缝纫B。

2) 在继续往前踩踏板为高速缝纫A。(但是,设定

了自动倒缝开关后,倒缝结束之后为高速缝纫。)

3) 轻轻踩踏板然后返还缝纫机停止C(机器默认出厂

设置为下停针)。

4) 向后踩踏板为切线动作E。

若有自动抬压脚功能时,在停止和切线之间增加半

后踏抬压脚功能开关。

向后轻轻踩踏板,为压脚提升动作D,再继续踩踏板

为切线动作。

始缝的自动倒缝过程中,把踏板返还中立位置则缝

纫机倒缝动作结束后停止。

高速缝纫或低速缝纫中向后用力踩踏板缝纫机均

可切线。

缝纫机切线中把踏板返还中立位置,但机器仍然把线

切完。

缝纫机停止机针下降之后,如果想升起机针时,请

往后踩一次踏板。

1.The pedal is operated in the following four steps.

1) The machine runs at low sewing speed when you lightly depress the from part of the pedal .

2) The machine runs at high sewing speed when you further depress the front part of the pedal . (If the automatic reverse feed

stitching has been preset, the machine runs at high speed after it completes reverse feed stitching.)

3) The machine stops (with its needle up or down) when you reset the pedal to its original position .

4) The machine trims threads when you fully depress the back part of the pedal.

·If your machine is provided with the Auto-lifter (AK Series). An addition step is given between the machine stop and thread

trimming step.

The presser foot goes up when you lightly depress the back part of the pedal, and if you further depress the back part, the

thread trimmer is actuated.

·If you reset the pedal to its neutral position during the automatic reverse feed stitching at seam start, the machine stops after

it completes the reverse feed stitching.

·The machine will perform normal thread trimming even if you depress the back part of the pedal immediately following high

or low speed sewing.

·The machine will completely perform thread trimming even if you reset the pedal to its neutral position immediately after the

machine started thread trimming action.

·When the machine stops with its needle down, and if you want to bring the needle up, depress the back part of the pedal

once.

Pedal operation

使用说明书

2SHUDWLQJ,QVWUXFWLRQV

11.线张力的调整

Adjusting the needle thread tension

1.上线张力的调整

1) 把第一线张力螺母向顺时针方向(A方向)转动,上

线张力变强。

2) 把第一线张力螺母向逆时针方向(B方向)转动,上

线张力变弱。

3) 把线张力螺母2向右C方向逆转,上线张力变强。

4) 向左D的方向转动则变弱。

1. Adjusting the needle thread tension

1) As you turn thread tension No.1 nut ① clock wise

(indirection A), the thread remaining on the needle after

thread trimming will be shorter.

2) As you turn nut ① counter clock wise (indirection B), the

thread length will be longer.

3) As you turn thread tension nut ② clock wise (indirection

C), the needle thread tension will be increased.

4) As you turn nut ② counter clock wise (indirection D), the

needle thread tension will be decreased.

6

11.线张力的调整

1. 要改变挑线弹簧 的行程时

1) 拧松固定螺丝 .

2) 把夹线螺钉 向右A的方向转动则变大。

3) 向左B的方向转动则变小。

2. 要改变挑线弹簧1的压力时

1) 拧松固定螺丝 ,卸下大夹线器组件 。

2) 拧松夹线螺钉固定螺丝 进行调整。

3) 把夹线螺钉 向右A的方向转动则变强。

4) 向左B的方向转动则变弱。

①

②

③

②⑤

④

③

Adjusting the needle thread tension

12.挑线弹簧

Thread take-up spring

1. Changing the stroke of thread take-up spring ①

1) Loosen setscrew ②.

2) As you turn tension post ③ clock wise (indirection A), the

stroke of the thread take-up spring will be increased.

3) As you turn the knob counter clock wise (indirection B),

the stroke will be increased.

2. Changing the pressure of thread take-up spring ①

1) Loosen setscrew ②, and remove thread tension (asm.) ⑤.

2) Loosen setscrew ④.

3) As you turn tension post ③ clock wise (indirection A), the

pressure will be increased.

4) As you turn the post counter clock wise (indirection B),

the pressure will be decreased.

使用说明书

2SHUDWLQJ,QVWUXFWLRQV

2. Adjusting the bobbin thread tension

1) As you turn tension adjust screw ③ clock wise

(indirection E), the bobbin thread tension will be increased.

2) As you turn screw ③ counter clock wise (indirection F),

the bobbin thread tension will be decreased.

13.压脚提升

Hand lifter

1) 让压脚停止到上升的位置,把压脚扳手①提到

A的方向。

2) 压脚约上升5.5mm(厚料机种为6mm)停止,压脚

扳手向B的方向落下压脚则返还原来的位置。

3) 膝动提升的标准量为10mm,最大可上升约

13mm。

1) To stop the machine with its presser foot up, turn hand

lifter lever ① in the direction A.

2) The presser foot will go up about 5.5mm (6mm for thick

material) and stop.

The presser foot will go back to its original position when

hand lifter lever is turned down in direction B.

3) Using the knee lifter, you can get the standard presser

foot lift of about 10 mm and the maximum lift of about 13

mm .

A

B

2.底线张力的调整

1) 把底线张力螺丝③向右E的方向转动,底线张力变强。

2) 向左F的方向转动则变弱。

7

14.压脚压力的调节

1) 拧紧螺母②,把压脚调节螺钉①向右A方向转,

力变强。

2) 线左B方向转,力变弱。

3) 调节后,拧紧螺母②。

4) 一般布料时,压脚调节螺钉的标准高度为

29~32mm。

Presser foot pressure

1) Loosen nut ②. As you turn presser spring regulator ①

clockwise (in direction A), the presser foot pressure will be

increased.

2) As you turn the presser spring regulator counter.-

clockwise (in direction B), the pressure will be decreased.

3) After adjustment, tighten nut ②.

4) For general fabrics, the standard height of the presser

spring regulator is 29 to 32 mm.

15.送布相位的调节

1) 拧松送布偏心凸轮①的固定螺丝②、③,朝箭

头方向或反箭头方向移动送布偏心凸轮,然后拧紧

固定螺丝。

2) 标准调节位置是送布牙从针板往下落时,送布

牙上面与针孔上端对准针板上面的位置。

3) 提早送布相位以防止布偏斜时,请向箭头方向

移动送布偏心凸轮。

4) 为了良好的紧线而推迟相位时,请逆箭头方向

移动偏心凸轮。

Adjusting the feed timing

1) Loosen screws ② and ③ in feed eccentric cam ①,

move the feed eccentric cam in the direction of the arrow or

apposite direction of the arrow, and firmly tighten the screws.

2) For the standard adjustment, adjust so that the top

surface of feed dog and the top end of needle eyelet are

flush with the top surface of throat plate when the feed dog

descends below the throat palte.

3) To advance the feed timing in order to prevent uneven

material feed, move the feed eccentric cam in the direction

of the arrow.

4) To delay the feed timing in order to increase stitch

tightness, move the feed eccentric cam in the opposite

direction from the arrow.

使用说明书

2SHUDWLQJ,QVWUXFWLRQV

AB

②

①

8

16.送布牙的倾斜

1) 标准倾斜(水平)度是送布轴的刻点A和牙架座①

的B部下降到20度水平送布轴侧的位置。

2) 为了防止缝制皱褶,向前抬起送布牙时,请拧

松紧固螺丝 ,把螺丝刀插入送布轴,然后沿箭头方

向转90度。

3) 为了减少布的偏斜,向前下降送布牙时,请沿

与前头方向相反方向转90度。

②

1)The standard tilt (horizontal of the feel dog is obtained

when marker dot A on the feed bar shaft is aligned with

marker dot A on feed rocker ①.

2)To tilt the feed dog with its front up in order to prevent

puckering, loosen the set screw , and turn the feed bar shaft

90 degrees in the direction of the arrow, using a screw

driver.

3)To tilt the feed dog with its from down in order to

prevent uneven material feed, turn the feed bar shaft 90

degrees in the opposite direction from the arrow.

②

1) 送布牙 a 从针板 突出的量请调整为

0.8~1.0mm。(厚料时为1.0~1.2mm)。

2) 缝制薄料时,送布牙伸出过高时容易起褶。

(0.7~0.9mm为适当。)

3) 调节送布牙时。

·拧松上下抬牙叉形曲柄①的固定螺丝②。

·上下移动牙架进行调节。

·然后拧紧固定螺丝②。

(注意) 拧得不紧时,会损伤叉口部。

b

Tilt of the feed dog

17.送布牙的高度

Height of the feed dog

1) The feed dog is factory-adjusted so that it jut out from the

throat plate surface 0.8 to 1.0 mm (1.0 to 1.2 mm for thick

material)

2) If the feed dog just out too much puckering may result

when sewing tight-weight materials (Recommended

protrusion 0.7 to 0.9 mm)

3) To adjust the height of the feed dog

·Loosen screw ② of crank ①.

·Move the feed barcker up or down to make adjustment.

·Securely tighten screw ②.

(Caution) If the clamping pressure is insufficient, the forked

portion will wear out.

注意

为了防止意外的启动造成的事故,请关掉电源后进行。

CAUTION

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

注意

为了防止意外的起动造成的事故,请关掉电源后进行。

CAUTION

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

Front up

Standard

Front

down

Throat

plate

前上方

标准

前下方

针板

普通型

0.~.mm810

厚料

1.0~ mm1.2

Feed dog

Throat plate

送布牙

针板

使用说明书

2SHUDWLQJ,QVWUXFWLRQV

②

0.9mm

261-140342

261-140342-A

标准

Standard

1.1mm

261-160362

薄料

0.~0. mm79

9

18.机针与旋梭的关系

Needle-to-hook relationship

1)转动手轮,让针杆降到最低点,然后拧松针杆

连接柱固定螺丝①。

(决定针杆高度)

2)(DB/

134规格机针时)把针杆②的刻线 A 对准

针杆下轴套③的下端,然后拧紧针杆连接柱固定螺

丝①。

(DA/88x1规格机针时)把针杆②的刻线 C 对准针

杆下轴套③的下端,然后拧紧针杆连接柱固定螺丝①。

(决定旋梭a的安装位置)

3)(DB/134规格机针时)拧松旋梭固定螺丝,转动

带轮在针杆②上升的方向,把刻线 B 对准针杆下

套③的下端。

(DA/88x1规格机针时)拧松旋梭固定螺丝,转动带

轮在针杆

②上升的方向,把刻线 D 对准针杆下套③的下端。

4) 在此状态下,让旋梭尖⑤对准机针④的中心,

把机针与旋梭的间隙调整为0.04~0.1mm,然后拧

紧螺丝。

(注意)间隙过小的话,会损伤旋梭尖,间隙过大

的话,会跳针。

1. Adjust the timing between the needle and the hook as

follows:

1) Turn the handwheel to bright the needle bar down to the

lowest point of its stroke, and loosen set screw ①

(Adjusting the needle bar height)

2) (For a DB / 134 needle system) Align market line A on needle

bar ② with the bottom end of needle bar lower bushing ③,

then tighten set screw ①.

(For a DA / 88x1 needle system) Align market line C on needle

bar ② with the bottom end of needle bar lower bushing ③,

then tighten set screw ①.

(Adjusting position of the hook A )

3) (For a DB / 134 needle system ) Loosen the three hook

setscrews, turn the handwheel, and align marker line B on

ascending needle bar ② with the bottom end of needle bar

lower bushing ③.

(For a DA / 88x1 needle system) Loosen the three hook

setscrews, turn the handwheel, and align marker line D on

ascending needle bar ② with the bottom end of needle bar

lower bushing ③.

4) After making the adjustments mentioned the above steps

align hook blade point ⑤ with the center of needle ④.

Provide a clearance of 0.04 mm to 0.1 mm (reference value)

between the needle and the hook, then securely tighten

setscrews in the hook.

(Caution) If the clearance between the blade point of hook

and the needle is smaller than the specified value, the blade

point of hook will be damaged. If the clearance is larger,

stitch skipping will result.

19.压脚高度的调节

1) 变换压脚高度或角度时,请拆下面板孔橡胶塞拧

松压脚杆的固定螺丝①进行调节。

2) 调节后,再拧紧固定螺丝。

Adjusting the height of the presser foot

1) Loosen setscrew ①, and adjust the presser foot height

and the angle of the presser foot.

2) After adjustment, securely tighten the setscrew ①.

使用说明书

2SHUDWLQJ,QVWUXFWLRQV

①

10

使用说明书

2SHUDWLQJ,QVWUXFWLRQV

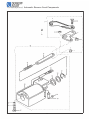

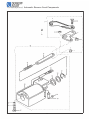

定刀的拆卸方法

1.将缝纫机放倒。

2.拆下紧固螺钉①和旋梭定位勾②。

3.拆下沉头螺钉③和定刀④。

移动刀的拆卸方法

1.用压脚扳手将压脚抬起。

2.拆下沉头螺钉⑤,取下针板⑥。

3.转动缝纫机主动轮,将针杆停止在最高位置。

4.拆下沉头螺钉 。

定刀压力的调节

1.拆下沉头螺钉

注1.拆针板⑥及动刀 时,请先取下机针。

组装按相反的顺序进行。

⑦,取下移动刀⑧

⑤,取下针板⑥;

2.用套筒扳手⑨松开定刀压力调节螺母⑩,把定刀压

力调节螺钉⑪适当往下调。

⑧

Removing the fixed knife

1.Tilt back the machine head

2 Remove the screw ①and rotating hook positioner②

3 Remove the screw③and the knife④

Removing the shift knife

1 Let the presser foot up by presser foot lever

2 Remove the screw ⑤and the needle plate.

3 Turn around the balance wheel, let the needle bar stop

highest

4 Remove the screw ⑦ and the knife⑧

Adjusting pressure of the fixed knife

1 Remove the screw ⑤ and the needle plate⑥.

2 Use the socket spanner ⑨ removing the screw⑩, moving

down the screw ⑪ to appropriate place.

Note:1 Remove the needle before removing the needle plate

⑥ and the shift knife ⑧.

Installation refer to the reverse order.

.

.

.

.

.

.

.

.

.

20.定刀与移动刀的转换

Change of fixed knife and shift knife

④

③

①

②

⑤

⑥

⑧

⑨

⑦

⑨

⑩

⑪

1)缝制厚料时,导线勾①向左 A 方向移动,挑线量变大。

2)缝制薄料时,导线勾①向左 B 方向移动,挑线量变小。

3)导线勾①的刻线 C 在螺丝的中心位置时是标准位置。

21.挑线杆挑线量的调节

Adjusting the thread take-up stroke

1) When sewing heavy-weight materials, move thread guide

① to the left (in direction A ) to increase the length of thread

pulled out by the thread take-up.

2) When sewing light-weight materials, move thread guide

① to the left (in direction B ) to decrease the length of thread

pulled out by the thread take-up.

3) Normally, thread guide ① is positioned in a way that

marker line C is aligned with the center of the screw.

11

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

DURKOPP ADLER 261_valid_till_november_2019 取扱説明書

- カテゴリー

- ミシン

- タイプ

- 取扱説明書

その他のドキュメント

-

Duerkopp Adler 261_vaild_from_december_2019 取扱説明書

Duerkopp Adler 261_vaild_from_december_2019 取扱説明書

-

ZOJE ZJ9000DA-D5S ユーザーマニュアル

ZOJE ZJ9000DA-D5S ユーザーマニュアル

-

ZOJE ZJ9513-G Parts Manual

ZOJE ZJ9513-G Parts Manual

-

ZOJE ZJ5303A-W-BD Parts Manual

ZOJE ZJ5303A-W-BD Parts Manual

-

ZOJE ZJ0303L-3-D3 Parts Manual

ZOJE ZJ0303L-3-D3 Parts Manual

-

Siruba DL918-NF Instruction book

-

Siruba 700Q+ Instruction book

-

Siruba DL7200B Instruction book

-

Siruba ML8000D Instruction book

-

Siruba C007L C007LX Instruction book