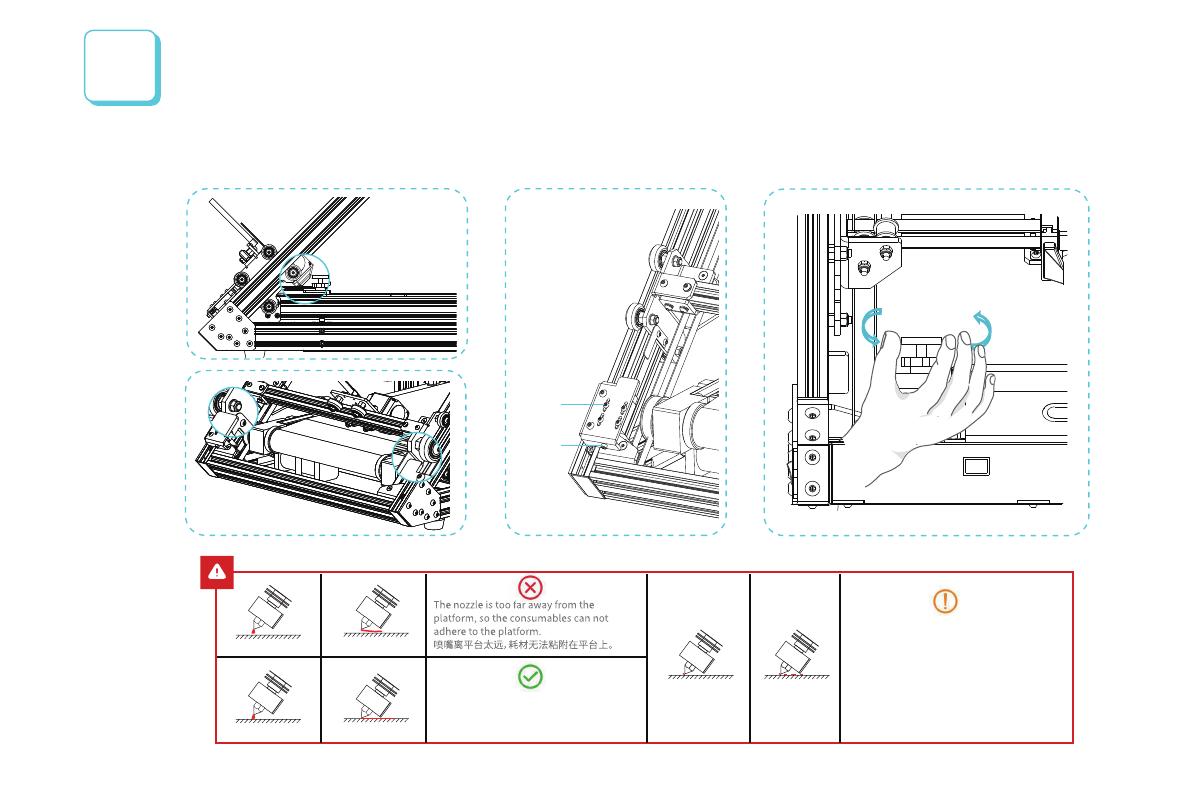

61.First move the X axis to the contact part between the nozzle and the belt (slightly press the nozzle onto the belt ) . 2.Push the two limit switches against the X sliding

block to lock the limit; 3. Press back on the screen to get the printer back to the origin; adjust the Y axis end-stop adjusting screw according to the position of the

nozzle relative to the belt after back to the origin in order to make sure the nozzle contacting with the belt rightly; then tighten the Y axis end-stop screw, leveling

finished; 4. if there is any seam or over contact between the nozzle and the belt, adjust the leveling nut slightly.

I

1.先把X轴移动到喷嘴与皮带接触位置(喷嘴微压皮

带) 2.将两个限位开关顶着X滑动块锁紧。3.点击屏幕中的回原点,使得机器自动回原点,根据回原点后喷嘴与皮带的相对位置调节Y轴限位调节螺丝; 使得回原点后喷嘴正好

与皮带接触,锁紧Y轴限位安装螺丝,调平完成。4.如果发现喷嘴与皮带有间隙或者接触过多,可微调调平螺母调节。

调平Leveling

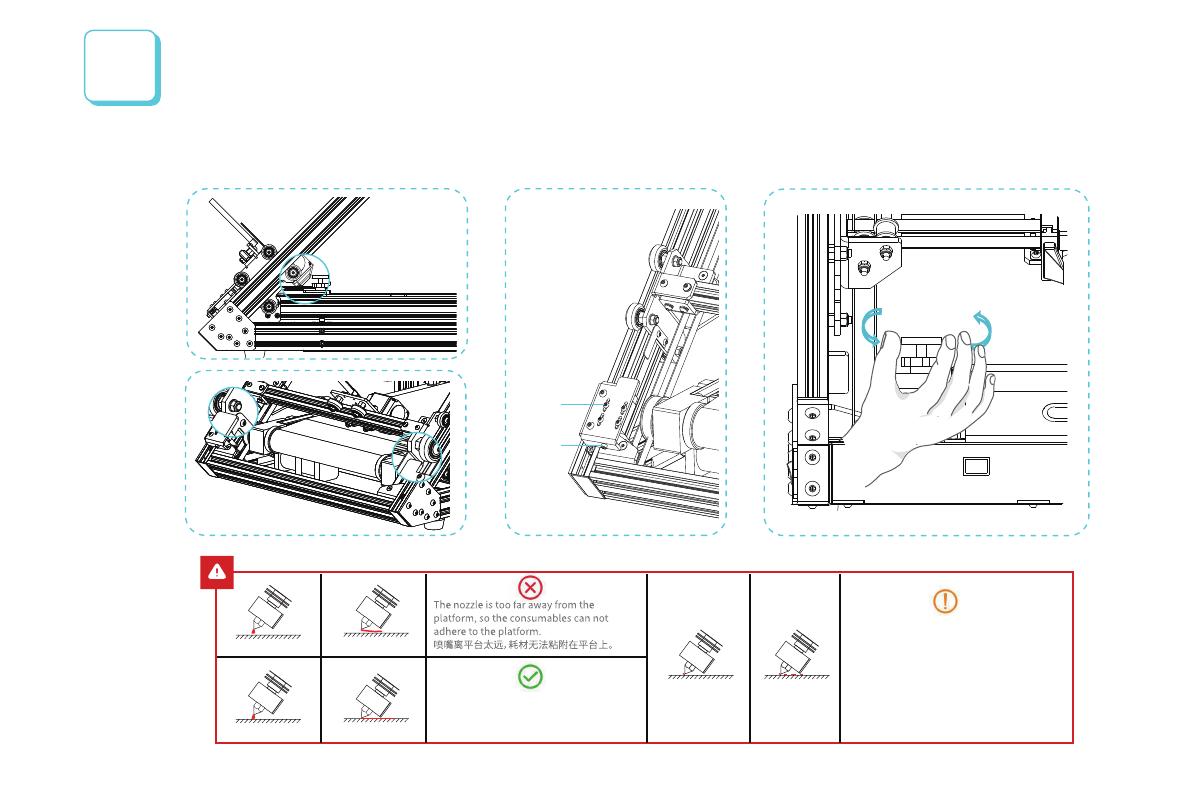

The even filament adheres right on the

platform.

The nozzle is too close to the platform,

the consumables are not extruded

enough, and the nozzle outlet is

damaged.Causes a plug and scratches

the belt.

耗材挤出饱满均匀,刚好贴在平台上。

喷嘴离平台太近,耗材挤出不足,喷嘴出口损伤,

造成堵头,刮伤皮带。

11

4

AY axis end-stop adjusting

screw

Y轴限位安装螺丝

BY axis end-stop

adjusting the screw

Y轴限位调节螺丝

3

A

B

2

1