E1E1E1

CP-UM-5978JECK

Digital Mass Flow Controller

Model F4Q

User’s Manual

Thank you for purchasing this product. This manual contains information

for ensuring the safe and correct use of the product. Those designing

or maintaining equipment that uses this product should first read and

understand this manual. Be sure to keep it nearby for handy reference.

Please read the “Terms and Conditions” from the following URL before

ordering or use:

https://www.azbil.com/products/factory/order.html

NOTICE

Please make sure that this manual is available to the user of the product.

Unauthorized duplication of this user’s manual in part or in whole is

forbidden. The information and specifications in this manual are subject to

change without notice. Considerable effort has been made to ensure that this

manual is complete and accurate, but if you should find an omission or error,

please contact us. In no event is Azbil Corporation liable to anyone for any

indirect, special, or consequential damages as a result of using this product.

SAFETY PRECAUTIONS

The safety precautions explained below aim to ensure safe and correct use

of this product in order to prevent injury to you and others, and to prevent

property damage. Be sure to observe these safety precautions. Also, make

sure you understand the safety guidelines before reading the rest of this

manual.

Key to symbols

WARNING

Warnings are indicated when mishandling this product

may result in death or serious injury.

CAUTION

Cautions are indicated when mishandling this product

may result in minor injury or property damage only.

WARNING

Never allow gases that are within explosive limits to pass through

this device. Doing so might result in an explosion.

Do not use the oxygen model for gas that contains oil. If this

should happen, never use the flow controller again for oxygen.

The oil on the gas-contacting parts may catch fire.

Do not use this device in explosive atmospheres or near flam-

mable fluids or steam.

Use this device within the operating ranges given in the specifica-

tions. Otherwise there is a danger of fire or device failure.

CAUTION

If you wish to use this device for a gas that is not stated in the

specifications, be sure to consult with us in advance. If this device

is used for a gas that is now allowed, device failure or deteriora-

tion of the O-ring seal may result.

Observe the following when using this device for oxygen gas:

• Piping should be done by a specialist experienced in handling

oxygen.

• Use degreased pipes and parts.

• Be sure to remove foreign matter, burrs, etc., from the pipes

before connecting this device.

• Do not touch the gas-contacting parts with bare hands.

If an external shutoff valve is closed, close this device’s valve also.

Otherwise device failure may result.

When carrying this device, hold the bottom. Otherwise injury or

device failure may result.

This device is a precision instrument. Do not drop it or subject it

to impact, or it might be damaged.

CAUTION

When carrying and storing the device, put it in a plastic bag, etc.,

to prevent foreign matter from entering the flow path.

If damage could result from the abnormal functioning of this de-

vice, include appropriate redundancy in the system design.

When mounting this device on a pipe, make sure that the top

panel does not faces downward. If the top panel faces downward,

device failure may result.

When installing, attach securely to prevent vibration. Vibration

may cause malfunction or device failure.

Install this device securely so that it does not come off. Otherwise

injury or device failure may result.

Do not connect a connector or supply power to this device if the

connector of this device is dusty or dirty. There is a danger of fire

or device failure.

Prevent foreign matter from entering the flow path of this device.

If rust, water droplets, oil mist, or dust from the pipes enters the

device, a measurement or control error may occur, or the device

may be damaged.

When using this device for air-fuel ratio control of a burner, pre-

vent the occurrence of flashback and also take countermeasures

for the instrumentation to protect the device even if flashback oc-

curs. Pressure increase or fire in the pipes caused by the backfire

of the burner could damage the device.

Do not connect equipment that causes a large throttling or pres-

sure loss near the piping that is downstream of this device. Doing

so may cause hunting.

Check the product connections and pipe connections for leak-

age before use. Also, check the connections for leakage regularly

after the start of use. It is the user’s responsibility to ensure that

gas leaks can be reliably detected. This is especially important if a

dangerous gas is used.

If the device is installed in an environment with significant tem-

perature change, flow a sufficiently dry gas through the pipes to

remove any remaining wet gas in order to prevent water conden-

sation. There is a danger of device failure.

Use this device within the flow rate range given in the specifica-

tions. To prevent excessive flow, use a suitable means to control

the supply pressure or use a throttle valve or the like to control

the flow rate. If the flow rate exceeds the upper limit, both the

flow rate display and the output voltage/current may indicate

considerably lower values than the actual flow rate.

Do not subject the product to pressure beyond the rated pressure

resistance range. The product may be damaged.

Use this device within the operating differential pressure range.

Otherwise hunting may occur and the valve may be damaged.

Do not blow air through the device or wipe the inside of the flow

path with a rag. Doing so may cause sensor malfunction.

Do not wash the device or steam-clean the inside of the flow

path. Doing so may cause sensor malfunction.

Do not apply excessive force on the cable or connector while the

cable is connected. Excessive force may damage the product.

Do not apply voltage to the instantaneous flow rate setting input ter-

minal while the power is off. Malfunction or device failure may result.

To release the fluid pressure inside the F4Q, vent the gas from the

outlet port.

Releasing the fluid pressure from the inlet port may affect the

rectifying section and cause errors in measurement and control.

UNPACKING

The following items should be included in your purchase.

• Mass flow controller: 1

• Separate display unit: 1*1

• Cable for separate display unit: 1*1

• User’s Manual No. CP-UM-5978JECK (this document): 1

• Inspection report: 1*2

*1. Only when the separable model was purchased.

*2. Only when the inspection report option was selected.

OVERVIEW

This mass flow controller incorporates the thermal micro-flow sensor devel-

oped by Azbil Corporation, and features high-speed response, high accuracy,

and high functionality.

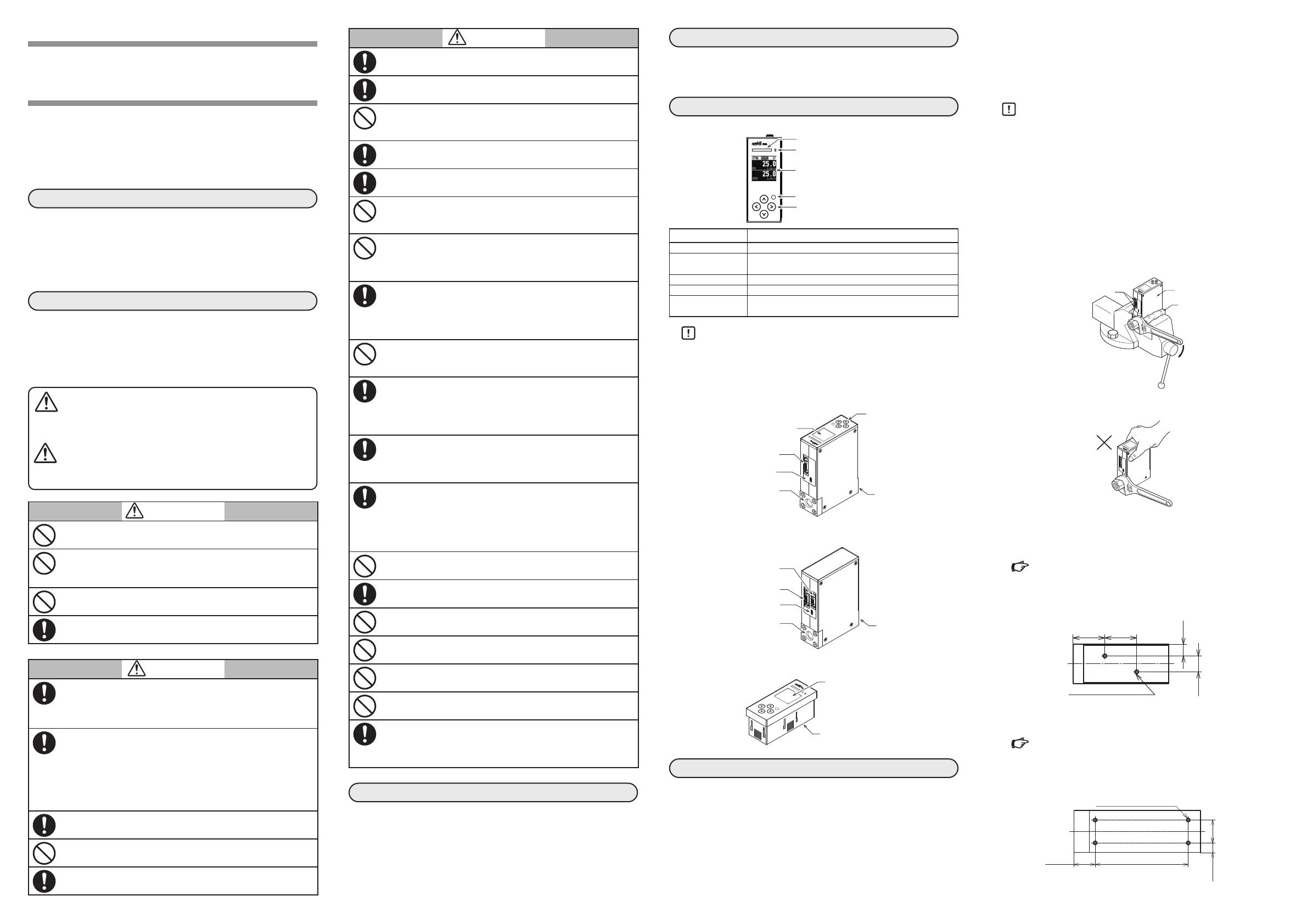

NAMES AND FUNCTIONS OF PARTS

Top panel

Part name Application

Status indicator An LED to indicate abnormalities or valve control status

Communication

indicator

An LED to indicate the communication status of the

device

Display Used to monitor controlled values or to specify settings.

Valve control key Used to switch valve operation modes.

Arrow keys Used for general purposes such as screen transitions,

cursor movement, and numerical value input.

Handling Precautions

• Do not press the keys with a screwdriver, needle, or other sharp-

tipped object. Device failure may result.

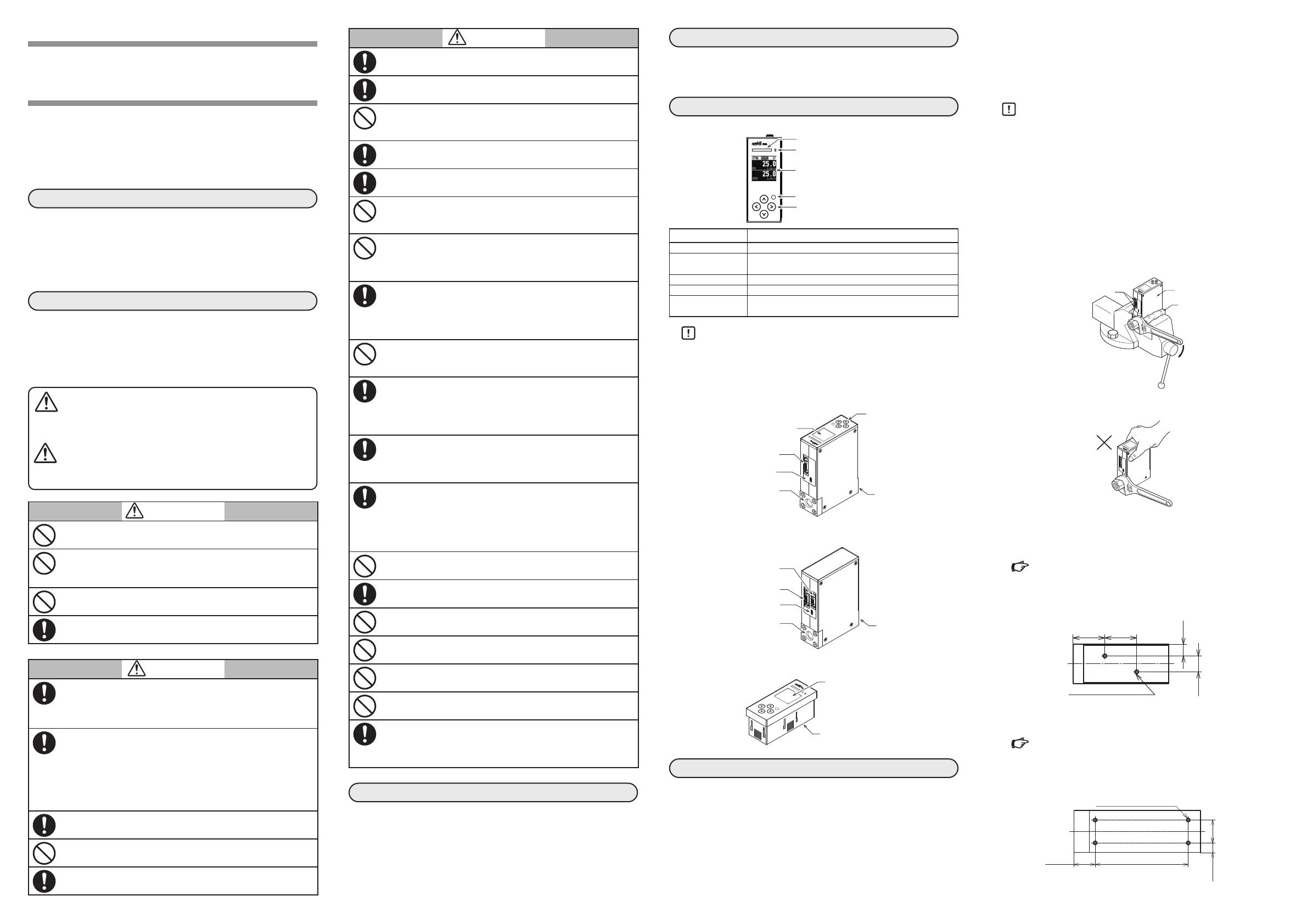

Main unit

z Integrated model

Connector for external connection

Micro USB terminal for loader

Display

Arrow keys

Top panel

Inlet pipe connection port Outlet pipe connection port

z Separable model

Connector for external connection

Connector for separate display unit

Micro USB terminal for loader

Inlet pipe connection port Outlet pipe connection port

Separate display unit

Display

Connector (on the back)

INSTALLATION

Installation location

Do not install this product in a place with any of the following

characteristics:

• Temperature or humidity outside the specified high and low limits

• Sudden temperature changes resulting in condensation

• Corrosive gases such as sulfide gas

• Flammable gas, liquid or vapor

• Large amounts of dust, salt, iron powder or other conductive sub-

stances, water droplets, oil mist, or organic solvents

• Mechanical vibration or shock outside the range of the specifications

• Direct sunlight, wind, or rain

• Splashing of fluids such as oil or chemicals

• Proximity to high-voltage lines, welding machines, or other sources of

electrical noise

• Strong electromagnetic fields

Handling Precautions

• The valve on this device cannot completely stop the flow of gas. If

complete shutoff is required, provide a separate shutoff valve.

• If there is a possibility of foreign matter entering the device,

install an upstream filter, strainer, or mist trap capable of elimi-

nating foreign matter 0.1 µm or greater in diameter. Be sure to

inspect and replace the filter at regular intervals.

Installation method

z Installing fittings for UNF connections

When attaching the fitting (on a UNF connection), hold the lower part

of the main unit in a vise gripped between rags to protect the finished

surfaces, and turn the fitting to tighten.

The device may be damaged if the lower part of it is not secured.

Main unit

Rag

Connector latches

Do not hold the upper part of the main unit when tightening the fitting.

Doing so may cause deformation and damage.

Installing the main unit

z Model F4Q9200/9500/0002/0005/0020/0050 (B,C)/0100

Installing the device using the F9Y4QB1 (an optional part) is

recommended.

User’s manual (CP-SP-1461E) for model F4Q (for information on

the F9Y4QB1)

The figure below shows the positions of the mounting holes on the base of

the device. Install the device with two M4 screws using the holes.

Unit: mm

M4 screw (2), depth 5 min.

30±0.5 30±0.5

11±0.5

15

±0.5

z Model F4Q0050 (J,K)/0200

Installing the device using the F9Y4QB2 (an optional part) is

recommended.

User’s manual (CP-SP-1461E) for model F4Q (for information on

the F9Y4QB2)

The figure below shows the positions of the mounting holes on the base of

the device. Install the device with four M4 screws using the holes.

Unit: mm

11.5±0.5

27 ±0.5

M4 screw (4), depth 5 min.

110±0.5

25.3±0.5

Valve control key

Arrow keys

Status indicator

Communication indicator

Display