© 2018 MIMAKI ENGINEERING CO.,LTD.

3.1 P. 3

INSTALLATION PROCEDURE MANUAL > Installation Procedure > Installation Procedure

Rev.

Model

OPT-J0475

Issued

2018.08.30

Revised

2019.08.23

Remarks

3.1 Installation Procedure

1.3

1

2

3

4

5

6

7

Connection with Ink supply attachment unit

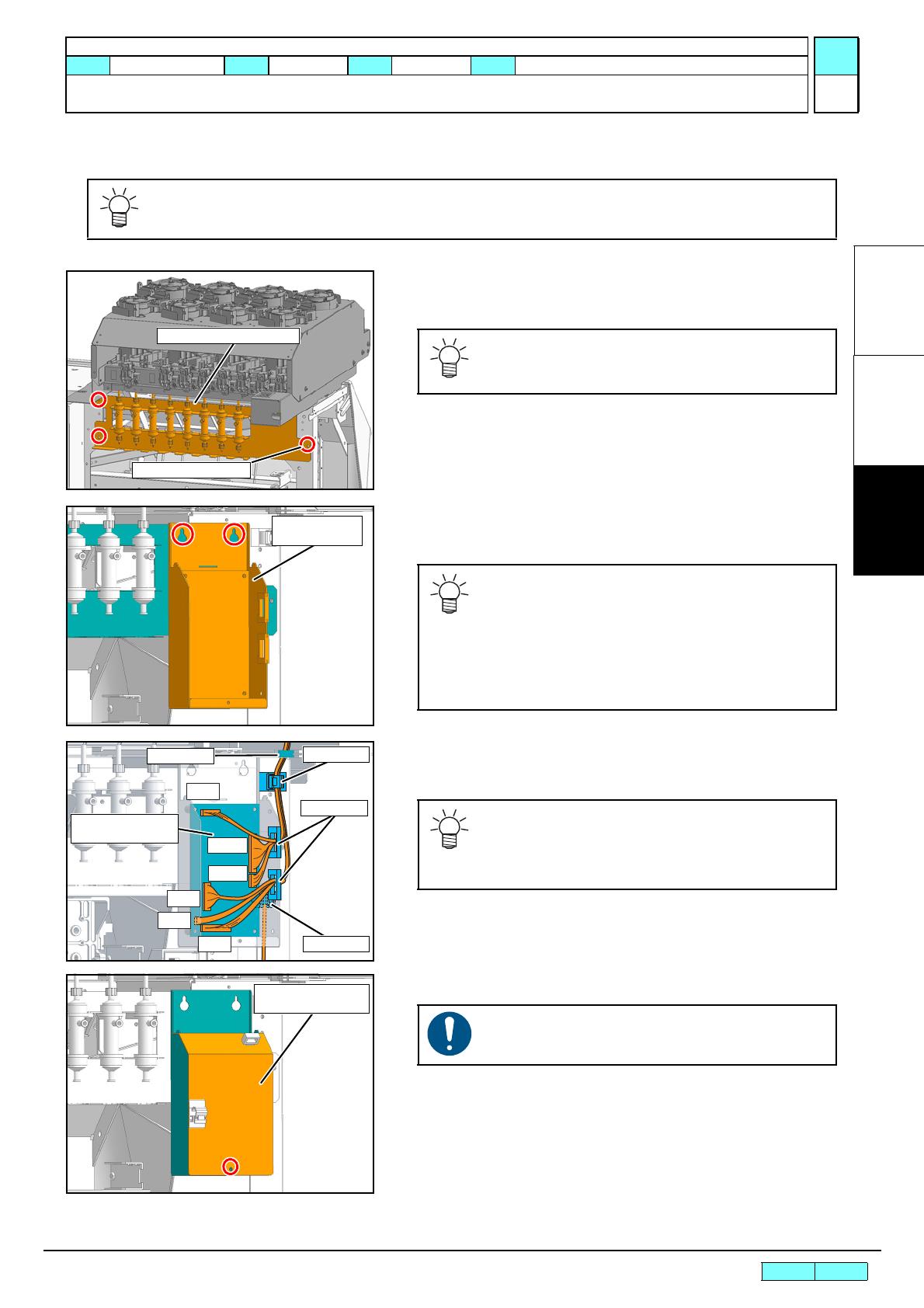

1. Attach the Degassing module Assy. (P4*10SMW black

screw x3)

2. Install the Ink IO PCB Assy. together with the Ink IO PCB

BKT in the Degassing module Assy. (Screw x2)

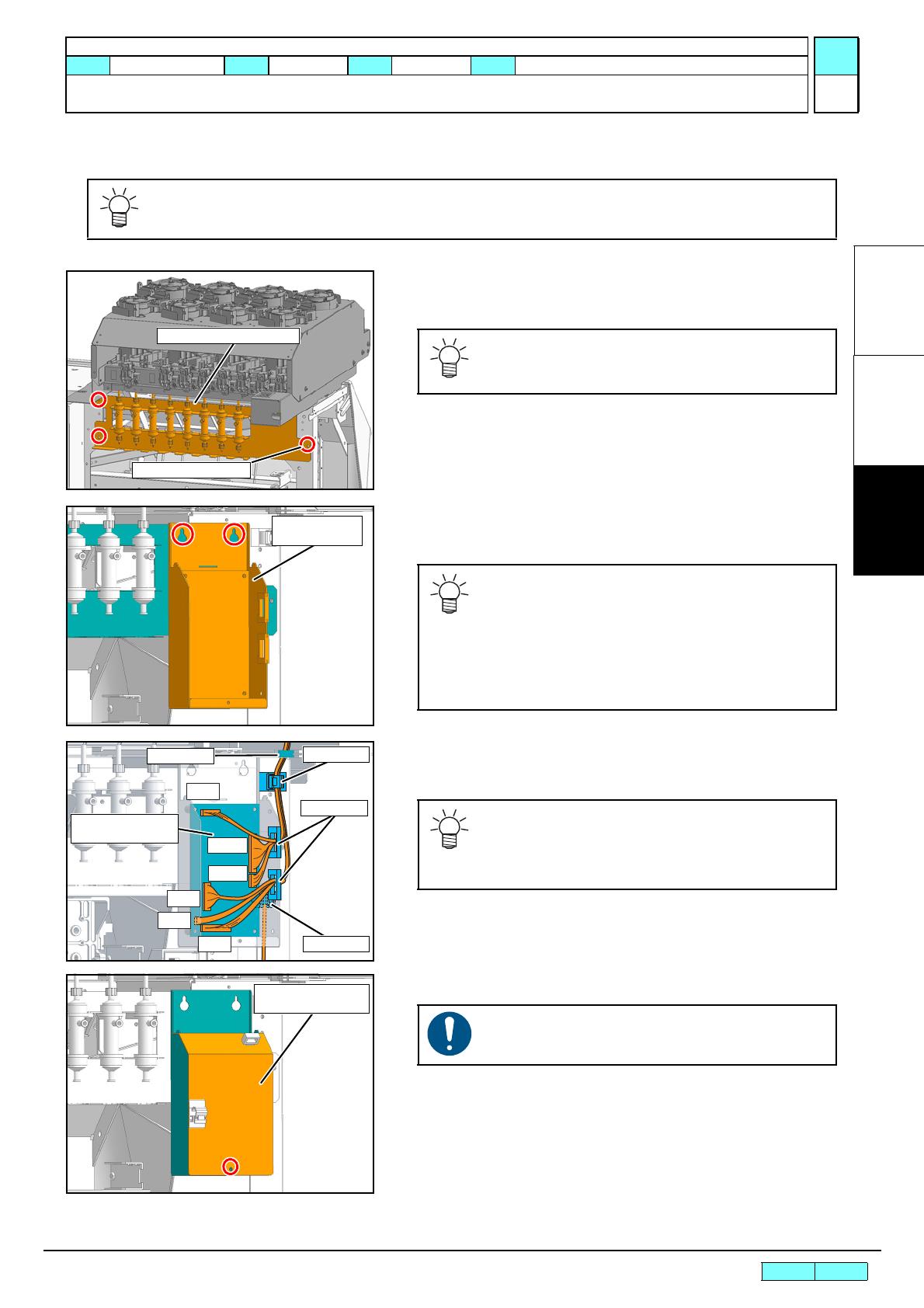

3. Connect the connectors to CN3, CN5, CN6, Cn7, CN12 and

CN13 on the Ink IO PCB Assy.

4. Fix the cable with a clamp.

5. Attach the Ink IO PCB bracket cover. (Screw x1)

Installation of the Ink supply attachment unit refers to [OPT-J0476 Ink supply attachment unit

Installation Procedure Manual (D501433)]

Degassing module Assy.

Temporal fastening

Fasten temporarily the screws at the right of

backside which will be fastened together in the

STEP7.

As for the Ink IO PCB BKT and the Ink IO PCB

Assy., use the ones removed in the procedure

[OPT-J0476 Ink supply attachment unit Instal-

lation Procedure Manual (D501433)].

It is easy to work by attaching screws (x2) for

the twin hole to Degassing module Assy.

beforehand.

Ink IO PCB

Assy.

Clamp

Clamp

Clamp

Clamp

As for the CN3 and CN6, connect the cables of

the main unit.

Remaining cables are to be collected in the Ink

IO PCB BKT and clamped.

Be careful not to pinch the cables.