TITLE:

Mini-Latch 2.5

FLANGE PIN TYPE TIN PLATING 製品仕様書

THIS DOCUMENT CONTAINS INFORMATION THAT IS PROPRIETARY TO MOLEX ELECTRONIC

TECHNOLOGIES, LLC AND SHOULD NOT BE USED WITHOUT WRITTEN PERMISSION

EN-127(2015-12)

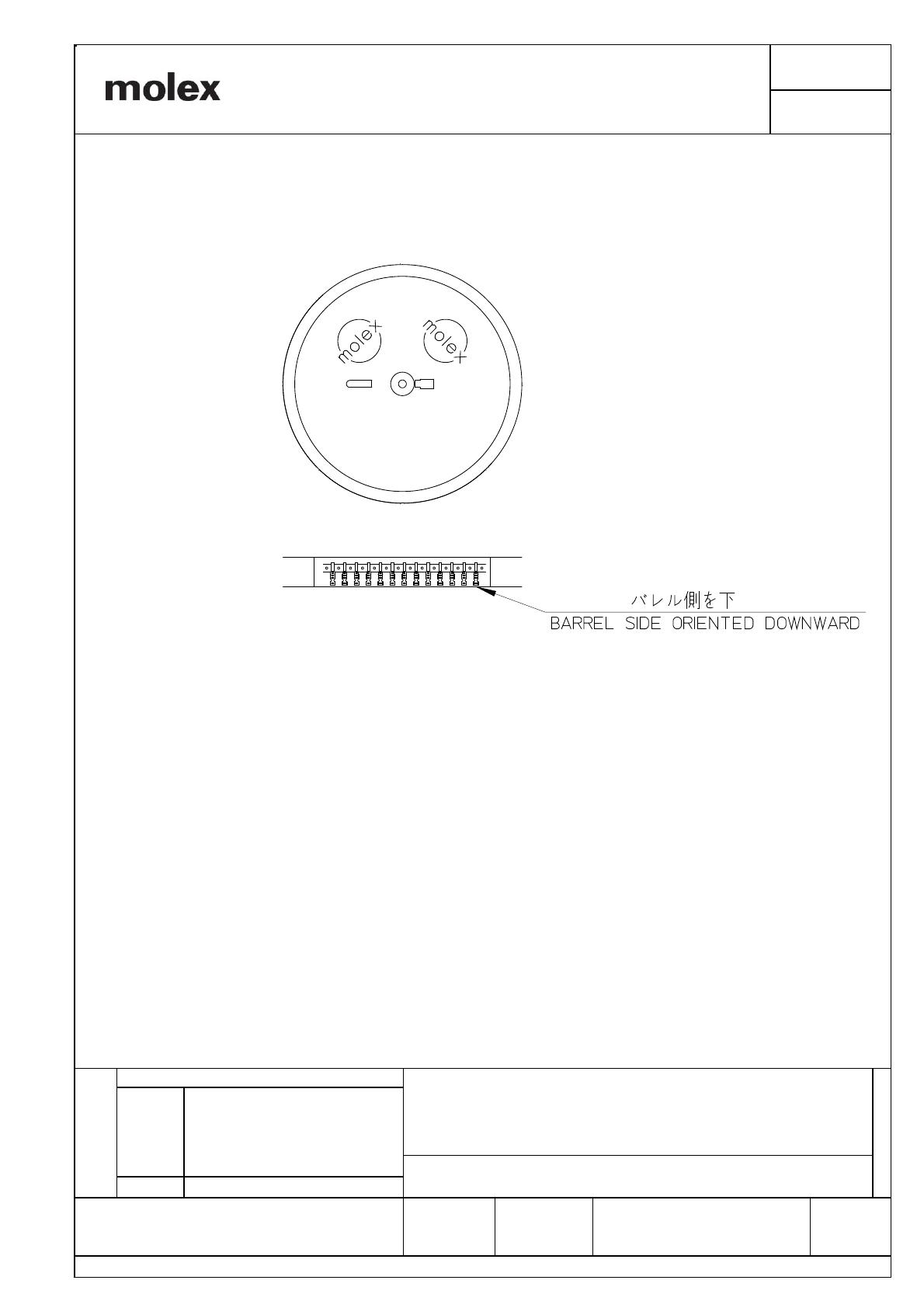

5. 本製品はセンターキャリア品の為、カートンよりリールを取り出し保管される場合には、

バレル側を下側にして保管願います。

バレル側を上にして保管されますと端子自重により巻き緩みが発生する恐れがあります。

When storing the terminal with remove the reel from the carton, please keep barrel down side.

Because this item has center career. Do not keep barrel up side. It could loosen the terminal.

図4リール保管時の向き

FIG.4 DIRECTION OF THE REEL STORAGE

6. 圧着機へリールを長時間掛けた状態でいますと、端子自重により巻き緩みが発生する恐れがあります。

ご使用にならない場合には、中間紙で端子全周を2~3周巻いた後、巻き緩みが生じない様、中間紙先端、

フランジ間のテープ止めをし、バレル側を下にして保管願います。

Do not put the reel in the crimping machine for long period. It could loosen the terminal. When it is not used,

after rolling interleaf twice, or three times into terminal all around, please keep barrel down side, with taping

tip of the interleaf and flange.

7. 圧着仕様を満足する為に、当社推奨圧着機のご使用をお願い致します。

In order to meet the crimp specification, please use our recommended crimping machine.

8. 外装カートン組立及び、中間紙繋ぎにステープル(ホチキス)は、使用しないで下さい。

Stapler prohibited in whole area with outer carton assembly, linking the interleaf .

.