-1- -2-

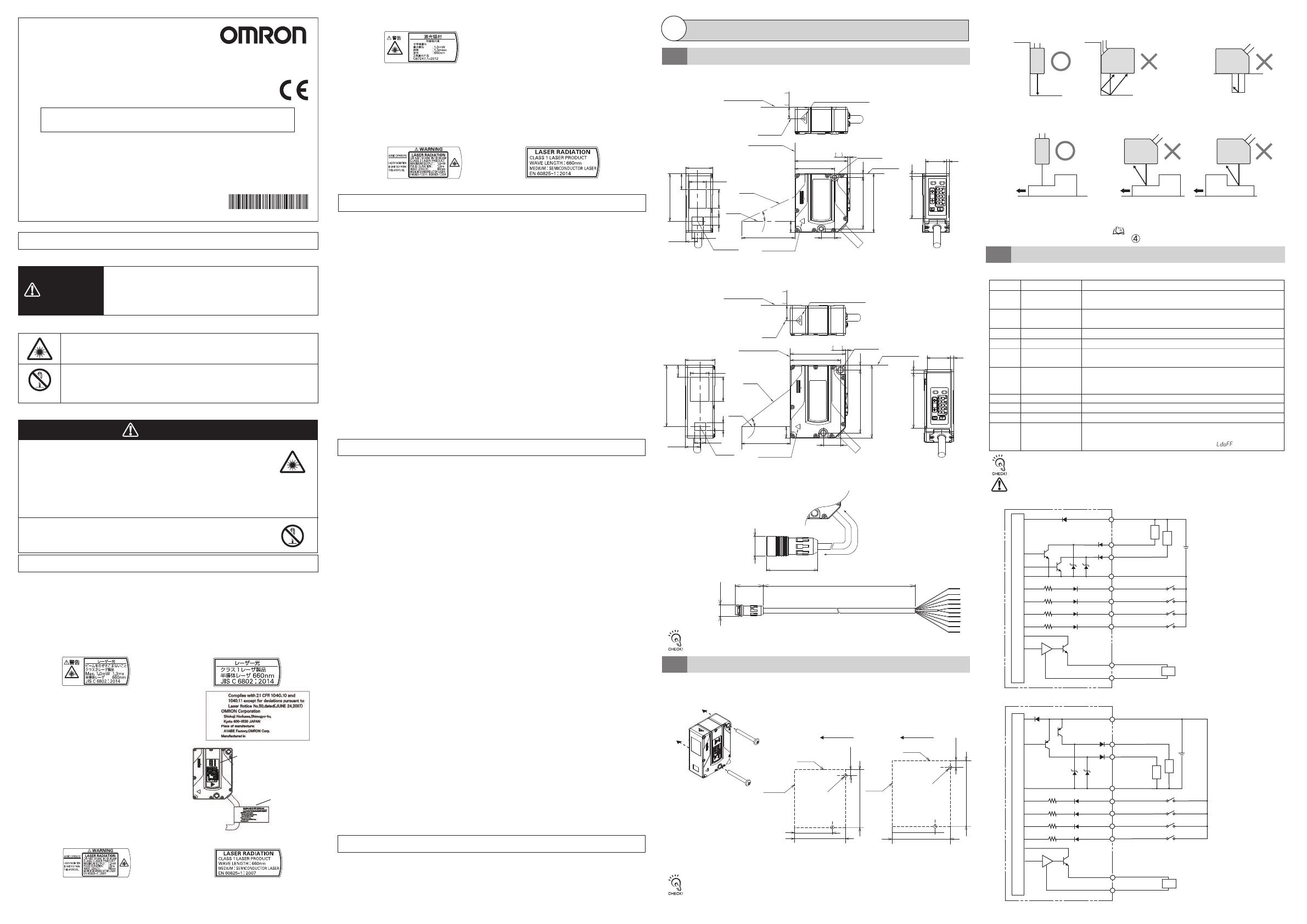

Laser WARNING label(FDA)

FDA Certification label

(FDA)

©

OMRON Corporation 2011 All Rights Reserved.

● Meanings of Signal Words

● Alert Statements

Laser Displacement Sensor CMOS Type

Smart Sensor

ZX1-LD

PRECAUTIONS ON SAFETY

SAFETY PRECAUTIONS FOR USING LASER EQUIPMENT

PRECAUTIONS FOR CORRECT USE

Checking the Package Content

Do not disassemble the product. Doing so may cause the

laser beam to leak, resulting in the danger of visual

impairment.

Indicates a potentially hazardous situation which, if

not avoided, will result in minor or moderate injury,

or may result in serious injury or death. Additionally

there may be significant property damage.

INSTRUCTION SHEET

■ Power Supply and Wiring

• Do not impose voltage exceeding the rated voltage: 10 to 30 VDC, including 10% ripple (p-p).

• When supplying power to the Sensor, make sure that the polarity of the power is correct, and do

not connect to an AC power supply.

• Do not short-circuit the load for the open collector output. Short-circuiting the load may cause

re or damage on the Sensor.

• Connect the load correctly. Short-circuiting the load may cause re or damage on the Sensor.

• Keep the load within the rated range. Overloading may result in re or damage on the Sensor.

• Wire the product cable separately from high-voltage or power lines. Placing them in the same

wiring or the same duct may cause induction, resulting in the product malfunction or damage.

• Always turn off the power of the Sensor before connecting or disconnecting the cable or

connector.

• Do not use the Sensor for the safety circuits in nuclear power or life-critical applications.

• Implement safety measures e.g. fail-safe circuits.

■ Installation

• Make sure that all installation screws must be tighten securely.

Tightening torque: M3, 0.5N·m (ZX1-LD50/ZX1-LD100)

M4, 1.2N·m (ZX1-LD300/ZX1-LD600)

■ Others

• Do not attempt to disassemble, deform by pressure, incinerate, repair, or modify this product.

• When disposing of the product, treat as industrial waste.

• If you notice an abnormal condition such as a strange odor, extreme heating of the unit, or

smoke, immediately stop using the product, turn off the power, and consult your dealer.

Laser safety measures for laser devices are stipulated both in Japan and overseas. Here, four

cases are described.

(1) Usage in Japan

The JIS C6802:2014 standard stipulates the safety precautions that users must take according

to the class of the laser product.

The ZX1-LD is classied into class 2 dened by this standard.

The ZX1-LDL is classied into class 1 dened by this standard.

■ Installation Location

Do not install the product in locations subjected to the following conditions:

• Surrounding air temperature outside the rating

• Rapid temperature uctuations (causing condensation)

• Relative humidity outside the range of 35 to 85%

• Presence of corrosive or ammable gases

• Presence of dust, salt, or iron particles

• Direct vibration or shock

• Reection of intense light (such as other laser beams, electric arc-welding machines, or

ultra-violet light)

• Direct sunlight or near heaters

• Water, oil, or chemical fumes or spray, or mist atmospheres

• Strong magnetic or electric eld

• In the water, rain, or outdoors

■ Power Supply and Wiring

• Do not supply the power to the Sensor before checking the I/O wiring.

• Ground the FG terminal when using a commercially-available switching regulator.

• If the power supply line is subject to surges, connect a surge absorber that meets the conditions

of the operating environment.

• Do not turn ON the power after wiring before making sure that the power supply is connected

correctly; there are no faulty connections, e.g. load short-circuits; the load current is correct.

Incorrect wiring may result in failure.

• Use a ZX0-XCR Extension Cable (sold separately) to extend the Sensor’s cable. Use only one

cable. Do not extend the cable for the Sensor to a length exceeding 20 m.

• The display and indicators turn ON after approx. 2.5 seconds after the power is turned ON.

• The sensor is certicated by the UL standard on the assumption of the following installation

conditions.

It is based on the assumption of usage in "Class 2 circuit". Please use it with "Class 2 power supply"

in the United States or Canada. The current rating of overcorrect protection is 0.8A max.

It is certicated as open type. The sensor shall be installed within an enclosure.

Rating of the cable is 30V. Please use it as internal cable wiring only in the end products equipment.

■ Warming Up

• After turning ON the power, allow the Sensor to warm up for approx. 30 minutes prior to use.

The circuitry is not stable immediately after turning the power ON, and the values gradually

change until the Sensor is completely warmed up. When using LD-OFF input for a long period

of time, perform warmng up for more than 30 minutes after cancelling LD-OFF.

■ Maintenance and Inspection

• Always turn OFF the power of the Sensor before connecting or disconnecting the cable or for

making adjustment.

• Do not use thinner, alcohol, benzene, acetone, or kerosene to clean the Sensor.

• If considerable foreign matter or dust collects on the glass surface of the front of Sensor, use a

blower brush (for camera lenses) to blow off the foreign matter. Avoid blowing it off with your

breath. For a small amount of foreign matter or dust, gently wipe with a soft cloth. Do not wipe

hard. The damaged glass surface may result in detection errors.

■ Sensing Object

The product cannot accurately measure the following types of objects: Transparent objects,

objects with an extremely low reective sensor ratio, objects smaller than the spot diameter,

objects with a large curvature, excessively inclined objects, etc.

• Sensor: 1

• Instruction sheet (this sheet): 1 each (Japanese and English)

• FDA Certication label : 1

• Laser Warning Label : 1 each Japanese, English(FDA), English and Chinese)

(The explanatory labels are attached to ZX1-LDL instead of the warning explanation labels.

Japanese, English(FDA) and English))

WARNING

● Explanation of Signs

● Laser beam

Indicates caution on potential laser beam hazard.

● Do not disassemble

Indicates prohibition when there is a risk of minor injury from

electrical shock or other source if the product is disassembled.

WARNING

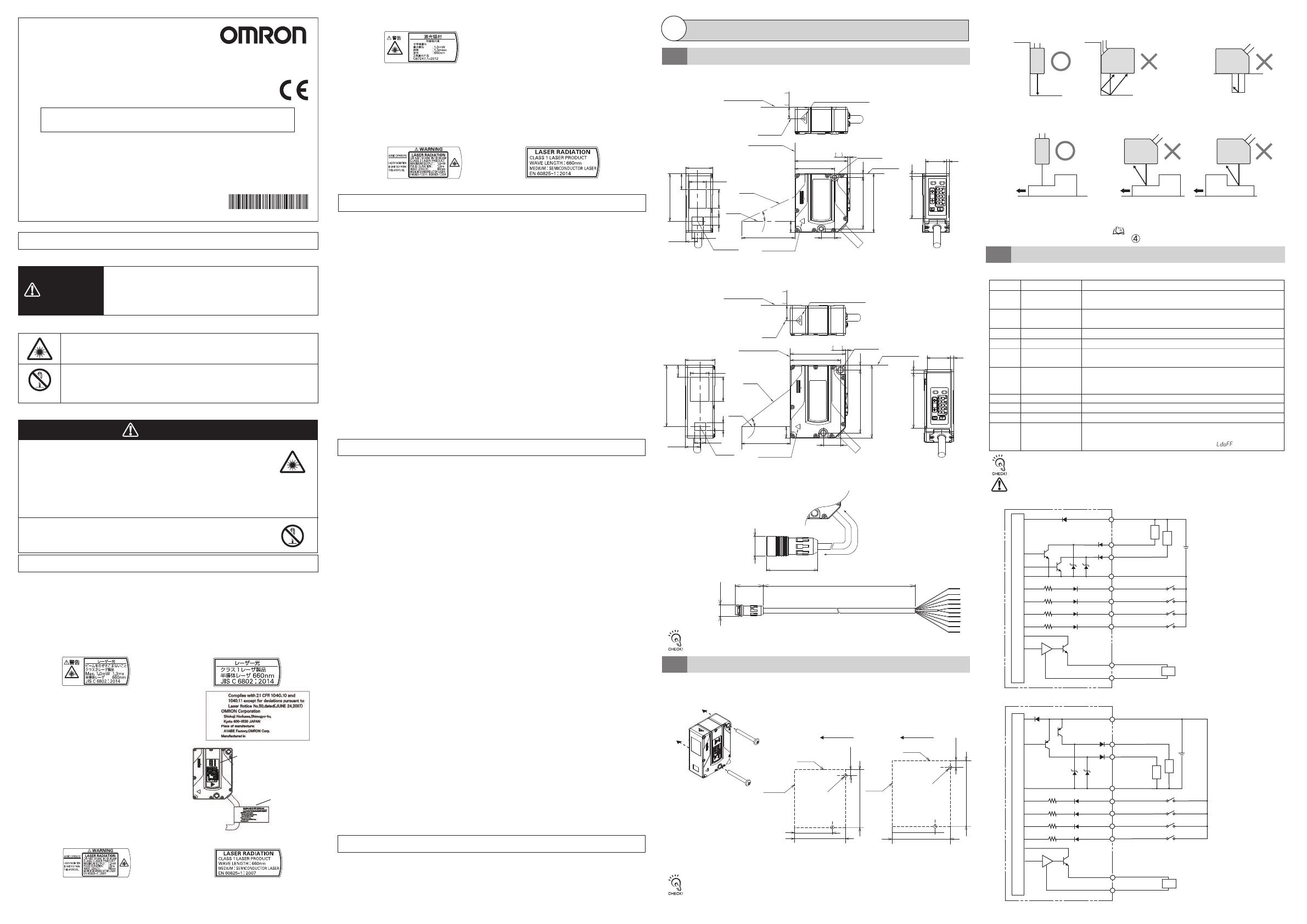

■ I/O Circuit Diagram <NPN Output Type>

■ I/O Circuit Diagram <PNP Output Type>

Installation

1

Dimensions

1-1

Wiring

1-3

The table below shows individual external I/O wires and their roles.

The individual wire colors and roles are the same between pre-wired and

connector joint models.

Wire the Sensor correctly. Unused wires must be insulated. Incorrect wiring may

result in damage to the Sensor.

Role

Brown

Wire color

Name

Connect to 10 to 30 VDC (including 10% ripple (p-p)). Used as the

common I/Os terminal for all I/O except monitor output for a PNP output type.

0-V power supply terminal. Used as the common I/Os terminal

for all I/O except monitor output for an NPN output type.

Blue GND

Outputs the CH1 judgment result.

White

OUT1 Judgment output

Outputs the CH2 judgment result.

Green

OUT2 Judgment output

TUNE1 input

TUNE2 input

Outputs the current value according to the measurement result.

(4 to 20 mA)

Black

Analog output

0-V ground line for analog output.

Connect this line separately from the blue (0 V) GND.

[Important] When analog output is not used, be sure to connect to blue (0 V).

Shield

Analog GND

Inputs tuning to CH1.

Inputs tuning to CH2.

Pink

Zero reset input

Used to execute or cancel zero reset.

Purple

Red

LD-OFF input

Power supply

Orange

■

■

10.2

A*

L*

1. 9

57

15.5

4.5

45.6

55.8

13.6

10.7

227

10.1

17

13.6

A*

L*

10.2

3.246.1

11. 7

2

35.3

Reference surface

2-3.2 dia.

(Mounting hole)

Receiver

axis

Emitter

axis

10.5

Emitter axis

42.3

10.5

14.23

16.77

10.1

15.1

* ZX1-LD50: L=50, A=21°

ZX1-LD100: L=100, A=11.5°

* ZX1-LD300: L=300, A=6.6°

ZX1-LD600: L=600, A=3.4°

Emitter center

Reference surface

Reference surface

Emitter

axis

Reference surface

2-4.5 dia.

(Mounting hole)

Reference surface

Emitter center

Receiver

axis

Emitter

axis

Thank you for selecting an OMRON product. This sheet primarily

describes precautions required in installing and operating the product.

• A specialist who has the knowledge of electricity must treat the product.

• Please read this manual carefully, and use it correctly after thoroughly

understanding the product.

• Please keep this manual properly for future reference whenever

it is necessary.

■ Labeling on Laser Use

The ZX1-LD has the following WARNING label or explanatory label on the side of the sensors.

Emitter center position mark

Emitter center

position mark

Emitter center position mark

Emitter center

position mark

Vinyl insulated round-shaped robot cable

Dia 6.5 9-wire (cross section of conductor:

0.125 mm2/insulator diameter: 0.7 mm)

Standard length: 2 m

Root section bending disabled length: 0 mm

Minimum bending radius: 39 mm

Vinyl insulated round-shaped robot cable

Dia 6.5 9-wire (cross section of conductor:

0.125 mm2/insulator diameter: 0.7 mm)

Standard length: 2 m

Root section bending disabled length: 0 mm

Minimum bending radius: 39 mm

Reference surface

10 to 30 VDC

Shield: Analog GND

Black: Analog output

300 Ω max.

Current output

4 to 20 mA

Red: LD-OFF input

Purple: Zero reset input

Pink: TUNE2 input

Orange: TUNE1 input

Blue: GND (0 V)

Green: OUT2

judgment output

White: OUT1

judgment output

Brown: 10 to 30 VDC

Load

Load

Internal circuit

Load

Shield: Analog GND

Black: Analog output

Red: LD-OFF input

Purple: Zero reset input

Pink: TUNE2

Orange: TUNE1

Blue: GND (0 V)

Brown: 10 to 30 VDC

Load

Internal circuit

Load

Load

10 to

30 VDC

Current output

4 to 20 mA

300 Ω max.

Green: OUT2

judgment output

White: OUT1

judgment output

PRECAUTIONS FOR SAFE USE

ZX1-LD3006/ZX1-LD6006

■ ZX1-LD506/ZX1-LD1006

15 dia.

37.3 L*

Ø 15.5

39.8

* The length of L is as follows:

ZX0-XC10R: 10 m, ZX0-XC20R: 20 m

The extension cable is the robot cable, the same as the cable of the Sensor Unit.

Vinyl insulated round-shaped robot cable

Dia 6.5 9-wire (cross section of conductor:

0.125 mm2/insulator diameter: 0.7 mm)

Standard length: 0.5 m

Sensor root section bending disabled length: 0 mm

Connector section bending disabled length: 40 mm

Minimum bending radius: 39 mm

To mount ZX1-LD50 and ZX1-LD100, use M3 screws (tightening torque: 0.5 N·m) and

ZX1-LD300 and ZX1-LD600, M4 screws (tightening torque: 1.2 N·m).

Mounting Sensor

1-2

Do not touch the sensor emitter and receiver sections. Correct detection may

not be possible if fingerprints are attached to these areas. If fingers have

inadvertently touched the areas, wipe the areas using a soft, clean cloth.

ZX1-LD300

ZX1-LD600

ZX1-LD50

ZX1-LD100

2-M3

P=0.5

3.2±0.1

49.3±0.1

23.6±0.1

35.3±0.1

4.5±0.1

2-M4

P=0.7

61.5±0.1

30.1±0.1

45.6±0.1

Reference

surface

Mounting hole dimensions (Unit: mm)

Emitter/Receiver direction

Reference

surface

Reference

surface Reference

surface

<Detection Near the Wall Surface>

<Detection of Workpiece with Level Difference>

<Cavity Detection>

Stable detection is possible

regardless of level difference.

Level difference may cause

an abnormal detection value.

The Sensor is less

inuenced by ambient

lighting.

The Sensor is easily inuenced by

ambient lighting, which may cause

detection value variations. *

Detection is not possible if

the emitter or receiver section

is blocked.

■ Caution on Mounting Direction

* Before performing tuning, apply mat paint on the wall surface or turn ON the background suppression

function to avoid laser light reection.

Refer to " 5. Background suppression function,

Detailed Settings"

The following precautions must be observed, since they are essential to ensure safety in operation.

■ Installation Environment

•Do not use the Sensor in locations subject to explosive or ammable gases.

• To ensure safety in operation and maintenance, do not install the Sensor near high-voltage

equipment or power devices.

ON: Laser turns OFF (radiation stop). In this state, analog output, digital

display, judgment output and judgment output display are output based on

keep function settings. The digital display shows [ ].

(2) USA

This product is subjected to the U.S. FDA (Food and

Drug Administration) laser regulations. The ZX1-LD

and ZX1-LDL is already reported to

CDRH (Center for Devices and Radiological Health).

Accession Number:

(ZX1-LD :1210041-000)

(ZX1-LDL :1210041-001)

When using a device equipped with the The ZX1-LD

and The ZX1-LD L in the U.S., attach an FDA

certication label on the sensor at the correct location as

indicated,and replace the warning label or explanatory

label with corresponding English Label(FDA).

The ZX1-LD is classied into Class 2 by the IEC

60825-1:2007 standard according to the regulations of

Laser Notice No.50 of the FDA standard.

The ZX1-LDL is classied into Class 1 by the IEC

60825-1:2007 standard according to the regulations of

Laser Notice No.50 of the FDA standard.

(3) China

The ZX1-LD is classied into Class 2 by the GB7247.1:2012 standard. When using in China,

warning labels must be replaced by Chinese ones supplied with the product.

The ZX1-LDL is classied into Class 1 by the GB7247.1:2012 standard.

(4)Usage in countries other than Japan, U.S. and China

・When usage in countries other than Japan, U.S. and China, warning labels must be replaced by

suitable for the area ones supplied with the ZX1-LD□□. When exporting to Europe, labels fall

under EU standard EN60825-1:2014. The ZX1-LD□□ is classied into Class 2 by the IEC

60825-1:2014 / EN 60825-1:2014 standard.

Do not expose your eyes to the laser radiation either directly

(i.e., after reflection from a mirror or shiny surface). Loss of

sight may possibly occur in case of the exposure to laser

high power density.

Caution - Use of controls or adjustments or performance of

procedures other than those specified herein may result in

hazardous radiation exposure

*0199560-4H*