DOC023.97.80356

Accu4

™

(T53, 8320)

01/2013, Edition 1

User Manual

用户手册

English...................................................................................................................................................................................................3

中文.......................................................................................................................................................................................................29

2

Table of contents

Specifications on page 3 Operation on page 18

General information on page 4 Maintenance on page 23

Installation on page 7 Troubleshooting on page 24

User interface and navigation

on page 17

Replacement parts and accessories

on page 27

Startup on page 18

Specifications

Specifications are subject to change without notice.

Model 8320 turbidity sensor

Specification Details

Operational:

Flow rate 0.19 to 26.5 LPM (0.05 to 7 GPM)

Ambient conditions 0 to 60 °C (32 to 140 °F)

Sample temperature

range

0 to 60 °C (32 to 140 °F)

Pressure range 0–3.4 bar at 20 °C (0–50 psig at 68 °F)

Pressure drop 0.0001 bar at 0.36 LPM (0.0017 psig at 0.1 GPM)

Residence time 3.8 LPM (9.5 seconds at 1 GPM)

Air venting Integral bubble trap for 0.19 to 1.9 LPM (0.05 to

0.5 GPM) flows.

Installation of an external bubble trap and a restrictor

valve on the sensor outlet is recommended for flows

above 1.9 LPM (0.5 GPM) with air in the sample.

Refer to Use an external bubble trap on page 27.

Mechanical:

Light sources Two near-infrared (880 nm wavelength) LEDs

Specification Details

Power requirements 5 V supplied by the controller to the light sources

and detectors

Process connections ½–in. NPT female standard; adaptable to

3

/

8

–in. or

¼–in. NPT, barb or tube fittings

Wetted materials PVC, polycarbonate, polystyrene, PPO, nitrile and

Buna-N

Enclosure Molded fiber-glass-reinforced polyester (flame

retardant) with four brackets for surface mounting

Dimensions (W x D x H) 285 x 172 x 400 mm (11.21 x 6.79 x 15.75 in.)

Net weight 4.5 kg (10 lb) approximately

Certifications 15 year environmental friendly use period

Model T53 controller

Specification Details

Operational:

Display Graphic dot matrix LCD, 128 x 64 pixels with LED

backlighting; 13 mm (½–in.) main character height;

3 mm (

1

/

8

–in.) auxiliary information character height;

menu screens contain up to six lines of text

Ambient conditions Operation: –20 to 60 °C (–4 to 140 °F); 0–95% relative

humidity, non-condensing

Storage: –30 to 70 °C (–22 to 158 °F); 0–95% relative

humidity, non-condensing

Pollution degree 2

Installation category II

Protection class I

Altitude 2000 m (6561 ft) maximum

English 3

Specification Details

Sensor-to-controller

distance

9 m (30 ft) maximum

1

Power requirements 90–130 VAC (115 VAC nominal) or 180–260 VAC

(230 VAC nominal), 50/60 Hz, 10 VA maximum

Relays Four electromechanical relays; SPDT (Form C)

contacts; 115/230 VAC, 5 A @ 30 VDC resistive

Analog outputs Two isolated 0.00–20.00 mA or 4.00–20.00 mA outputs

each with 0.004 mA (12–bit) resolution; up to 600 ohm

load capacity

Mechanical:

Enclosure NEMA 4X; polycarbonate face panel, epoxy-coated

cast aluminum door and case with four 13-mm (½–in.)

cable entry holes, nylon mounting bracket and stainless

hardware

Mounting Panel, surface or pipe mount

Net weight 2.3 kg (5 lb)

Fuses One type T, 80 mA, 250 V slow-blow fuse for the 230 V

line power circuits, 5 mm x 20 mm; one type T,

100 mA, 250 V slow-blow fuse for the 115 V line power

circuits, 5 mm x 20 mm

Certifications 15 year environmental friendly use period

Accu4 system performance:

Measurement range 0.000–100.0 NTU; auto-ranging and automatic decimal

point shift above 1.000 NTU and 10.00 NTU (same for

other measurement units)

Measurement units NTU, TEF, FNU or FTU

Signal averaging 0 to 60 seconds

System accuracy ±2% of reading, all ranges

Sensitivity 0.001 NTU

Specification Details

Repeatability 0.1% of span or better

Temperature drift Zero and span: 0.01% of span per °C

1

Contact the manufacturer if a longer distance is necessary.

General information

In no event will the manufacturer be liable for direct, indirect, special,

incidental or consequential damages resulting from any defect or

omission in this manual. The manufacturer reserves the right to make

changes in this manual and the products it describes at any time, without

notice or obligation. Revised editions are found on the manufacturer’s

website.

Safety information

N O T I C E

The manufacturer is not responsible for any damages due to misapplication or

misuse of this product including, without limitation, direct, incidental and

consequential damages, and disclaims such damages to the full extent permitted

under applicable law. The user is solely responsible to identify critical application

risks and install appropriate mechanisms to protect processes during a possible

equipment malfunction.

Please read this entire manual before unpacking, setting up or operating

this equipment. Pay attention to all danger and caution statements.

Failure to do so could result in serious injury to the operator or damage

to the equipment.

Make sure that the protection provided by this equipment is not impaired.

Do not use or install this equipment in any manner other than that

specified in this manual.

Use of hazard information

D A N G E R

Indicates a potentially or imminently hazardous situation which, if not avoided, will

result in death or serious injury.

4 English

W A R N I N G

Indicates a potentially or imminently hazardous situation which, if not avoided,

could result in death or serious injury.

C A U T I O N

Indicates a potentially hazardous situation that may result in minor or moderate

injury.

N O T I C E

Indicates a situation which, if not avoided, may cause damage to the instrument.

Information that requires special emphasis.

Precautionary labels

Read all labels and tags attached to the instrument. Personal injury or

damage to the instrument could occur if not observed. A symbol, if noted

on the instrument, will be included with a danger or caution statement in

the manual.

This is the safety alert symbol. Obey all safety messages that follow

this symbol to avoid potential injury. If on the instrument, refer to the

instruction manual for operation or safety information.

This symbol indicates that a risk of electrical shock and/or

electrocution exists.

This symbol indicates the presence of devices sensitive to Electro-

static Discharge (ESD) and indicates that care must be taken to

prevent damage with the equipment.

Electrical equipment marked with this symbol may not be disposed of

in European public disposal systems after 12 August of 2005. In

conformity with European local and national regulations (EU Directive

2002/96/EC), European electrical equipment users must now return

old or end-of-life equipment to the Producer for disposal at no charge

to the user.

Note: For return for recycling, please contact the equipment producer or supplier

for instructions on how to return end-of-life equipment, producer-supplied

electrical accessories, and all auxiliary items for proper disposal.

This symbol, when noted on the product, identifies the location of a

fuse or current limiting device.

This symbol indicates that the marked item requires a protective earth

connection. If the instrument is not supplied with a ground plug on a

cord, make the protective earth connection to the protective

conductor terminal.

Certification

Canadian Radio Interference-Causing Equipment Regulation,

IECS-003, Class A:

Supporting test records reside with the manufacturer.

This Class A digital apparatus meets all requirements of the Canadian

Interference-Causing Equipment Regulations.

Cet appareil numèrique de classe A répond à toutes les exigences de la

réglementation canadienne sur les équipements provoquant des

interférences.

FCC Part 15, Class "A" Limits

Supporting test records reside with the manufacturer. The device

complies with Part 15 of the FCC Rules. Operation is subject to the

following conditions:

1. The equipment may not cause harmful interference.

2. The equipment must accept any interference received, including

interference that may cause undesired operation.

Changes or modifications to this equipment not expressly approved by

the party responsible for compliance could void the user's authority to

operate the equipment. This equipment has been tested and found to

comply with the limits for a Class A digital device, pursuant to Part 15 of

the FCC rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated

in a commercial environment. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference

to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference, in which case the user will be

required to correct the interference at their expense. The following

techniques can be used to reduce interference problems:

English

5

1. Disconnect the equipment from its power source to verify that it is or

is not the source of the interference.

2. If the equipment is connected to the same outlet as the device

experiencing interference, connect the equipment to a different

outlet.

3. Move the equipment away from the device receiving the interference.

4. Reposition the receiving antenna for the device receiving the

interference.

5. Try combinations of the above.

Product overview

D A N G E R

Chemical or biological hazards. If this instrument is used to monitor a

treatment process and/or chemical feed system for which there are

regulatory limits and monitoring requirements related to public health,

public safety, food or beverage manufacture or processing, it is the

responsibility of the user of this instrument to know and abide by any

applicable regulation and to have sufficient and appropriate

mechanisms in place for compliance with applicable regulations in the

event of malfunction of the instrument.

The Accu4 low-range turbidimeter system includes a Model

8320 turbidity sensor and Model T53 controller. Refer to Figure 1 and

Figure 12 on page 17. The system design meets the International

Standards for Measurement of Turbidity (ISO 7027) for FNU and

USEPA-approved GLI Method 2 for NTU.

This system is used to monitor the turbidity of potable water or filtered

water.

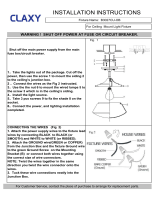

Figure 1 Model 8320 turbidity sensor overview

1 Calibration hose and funnel 6 Detectors (2x)

2 Terminal board 7 Door latch

3 Light sources (2x) 8 Inlet (½–in. NPT female)

4 Flow chamber 9 3-way value, internal

5 Outlet (½–in. NPT female) 10 Sensor cable

Product components

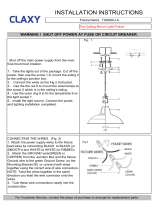

Make sure that all components have been received. Refer to Figure 2

and Figure 3. If any items are missing or damaged, contact the

manufacturer or a sales representative immediately.

6

English

Figure 2 Turbidity sensor components

1 Turbidity sensor 3 Mounting screws (4x)

2 Mounting brackets (4x)

Figure 3 Controller components

1 Controller 6 Flat washers, ¼–in. ID (8x)

2 Sealing gasket for panel mount,

Neoprene

7 Hex nuts, M6 (8x)

3 Mounting foot (2x) for panel mount 8 Pan head screws, M6 x 1.0 x

20 mm (4x)

4 Mounting bracket 9 Pan head screws, M6 x 1.0 x

100 mm for pipe mount (4x)

5 Ground screw, green 10 Pan head screws, M6 x 1.0 x

150 mm for panel mount (4x)

Installation

W A R N I N G

Multiple hazards. Only qualified personnel must conduct the tasks

described in this section of the document.

Installation guidelines

Install the turbidity sensor as near as possible to where the controller is

to be installed. Contact the manufacturer if a distance longer than 9 m

(30 ft) is necessary.

English

7

Make sure that the ambient conditions of the installation location of the

turbidity sensor and controller are within specifications. Refer to

Specifications on page 3.

Install the turbidity sensor indoors or outdoors where there is little or no

ambient vibration. Install the controller in a location that is:

• Clean and dry where there is little or no vibration

• As far as possible away from sources of vibration

• As near as possible to the water source

• Protected from corrosive fluids

Note: If exposed to direct sunlight, the operating temperature of the controller may

increase above the specified limit. Direct sunlight may also decrease the display

visibility. If necessary, use a sun shield (1000G3088-001).

Mechanical installation

Sensor mounting

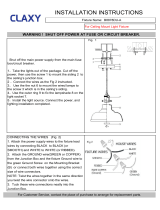

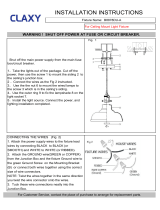

Install the turbidity sensor on a flat surface. Refer to the illustrated steps

in Figure 4. Mounting hardware is supplied by the user.

Figure 4 Sensor mounting

Controller mounting

Install the controller on a flat surface, panel or pipe (horizontal or

vertical). Refer to the instructions supplied with the controller mounting

hardware.

8

English

Electrical installation

W A R N I N G

Potential electrocution hazard. In order to maintain the NEMA/IP

environmental ratings of the enclosure, use only conduit fittings and

cable glands rated for at least NEMA 4X/IP66 to route cables in to the

instrument.

W A R N I N G

Potential Electrocution Hazard. Always disconnect power to the

instrument when making electrical connections.

• Put all wiring to the sensor and controller in ½-inch, grounded metal

conduit to protect the cable from moisture, electrical noise or

mechanical damage.

If only shielded cables are used, applicable strain reliefs or cable grips

are necessary. Accessory watertight cable grips (3H1091) and

locknuts (3H1230) are available from the manufacturer.

• Make sure that the diameter of the cables used is 4.3–11.4 mm (0.17–

0.45 in.) so that the cable strain reliefs hold the cables securely when

tightened.

• Do not put more than one cable in a cable strain relief.

• Close all unused cable entry holes with applicable plugs to keep out

moisture.

• Close all unused cable strain reliefs with rods or cables to keep out

moisture.

Electrostatic discharge (ESD) considerations

N O T I C E

Potential Instrument Damage. Delicate internal electronic components

can be damaged by static electricity, resulting in degraded

performance or eventual failure.

Refer to the steps in this procedure to prevent ESD damage to the

instrument:

• Touch an earth-grounded metal surface such as the chassis of an

instrument, a metal conduit or pipe to discharge static electricity from

the body.

• Avoid excessive movement. Transport static-sensitive components in

anti-static containers or packages.

• Wear a wrist strap connected by a wire to earth ground.

• Work in a static-safe area with anti-static floor pads and work bench

pads.

Wiring overview

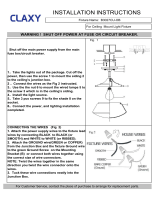

Figure 5 shows the wiring connections and fuses for the controller.

English 9

Figure 5 Wiring overview

1 Analog output connections (2x) 5 AC input power connections

2 RS232 connection (not used) 6 Fuses (2x)

3 TTL connection 7 Relay connections (4x)

4 Sensor cable connections 8 Grounding strip

General wiring procedure

W A R N I N G

Potential Electrocution Hazard. Always disconnect power to the

instrument when making electrical connections.

Connect wiring to the controller as shown in the illustrated steps in

Figure 6. When wiring is complete, close the controller cover and tighten

all the cover screws in order to maintain the NEMA/IP environmental

ratings of the enclosure.

10 English

Figure 6 General wiring procedure

Wiring for power

D A N G E R

Electrocution hazard. Protective Earth Ground (PE) connection is

required.

D A N G E R

Electrical shock and fire hazards. Make sure to identify the local

disconnect clearly for the conduit installation.

W A R N I N G

Potential Electrocution Hazard. If this equipment is used outdoors or in

potentially wet locations, a Ground Fault Interrupt device must be

used for connecting the equipment to its mains power source.

N O T I C E

Install the device in a location and position that gives easy access to the

disconnect device and its operation.

Supply power to the controller with conduit or a power cable. Make sure

that a circuit breaker with sufficient current capacity is installed in the

power line. The circuit breaker size is based on the wire gauge used for

installation.

For installation with conduit:

• Install a local disconnect for the controller within 3 m (10 ft) of the

controller. Put a label on the disconnect that identifies it as the main

disconnect device for the controller.

• Make sure that the power and safety ground service drops for the

controller are 18–12 AWG.

• Connect equipment in accordance with local, state or national

electrical codes.

• Connect the conduit through a conduit hub that holds the conduit

securely and seals the enclosure when tightened.

For installation with a power cable, make sure that the power cable is:

• Less than 3 m (10 ft) in length

English

11

• Rated for at least 60 °C (140 °F) and applicable to the installation

environment

• Not less than 18 AWG with applicable insulation colors for local code

requirements

• A power cable with a three-prong plug (with ground connection) that is

applicable to the supply connection

• Connected through a cable gland (strain relief) that holds the power

cable securely and seals the enclosure when tightened

• Does not have a locking type device on the plug

Wiring procedure

Refer to Table 1, Figure 5 on page 10 and General wiring procedure

on page 10 to connect the controller to power. Supply power to only one

terminal (terminal 3 or 4). Connect line power using the standard three-

wire connection arrangement.

Do not put the sensor cable (and interconnect cable, if used) in the same

conduit with power wiring. Electrical noise may interfere with the sensor

signal.

Table 1 AC power wiring information

Input voltage Terminal Description

Color—North

America

Color—EU

115 VAC,

single phase

3 Hot

Black Brown

230 VAC,

single phase

or split phase

4 Hot

115 or

230 VAC

2 Neutral (N) White Blue

— Protective

Earth (PE)

grounding

strip

Green Green with

yellow stripe

Connect the sensor cable

W A R N I N G

Potential Electrocution Hazard. Always disconnect power to the

instrument when making electrical connections.

Refer to General wiring procedure on page 10, Figure 7 and Table 2 to

connect the sensor cable to the controller.

Cut the sensor cable to the shortest applicable length before it is

connected to the controller to prevent unnecessary electrical noise that

may interfere with the sensor signal. Keep the cable away from motors

or other equipment that may give off electrical or magnetic fields.

Directly connect the sensor to the controller to remove potential

problems caused by wet environments and a junction box.

12 English

Figure 7 Connect the sensor cable

Table 2 Sensor cable wiring information

Terminal block Terminal

number

Wire color Terminal

number

Wire color

TB-1 12 Red 18 Brown

13 Violet 19 Grey

14 Green 20 Blue

15 White 21 Black

16 Yellow 22 Orange

Connect the inner shield wires to the grounding strip.

Connect the analog outputs (optional)

W A R N I N G

Potential Electrocution Hazard. Always disconnect power to the

instrument when making electrical connections.

The controller contains two isolated 0.00-20.00 mA or 4.00-20.00 mA

analog outputs (Output 1 and Outputs 2) that represent the measured

turbidity. Use the analog outputs for analog signaling or to control

external devices. Refer to Figure 5 on page 10 and General wiring

procedure on page 10 to connect the analog outputs. Refer to Configure

the analog outputs on page 19 for configuration information.

Make connections with twisted-pair shielded wire and connect the shield

to the grounding strip in the controller.

• Do not connect the shield at both ends of the cable.

• Use of non-shielded cable may result in radio frequency emission or

susceptibility levels higher than allowed.

• Maximum loop resistance is 600 ohms.

Notes:

• The analog outputs are isolated from the other electronics, but are not

isolated from each other.

English

13

• The analog outputs are self-powered. Do not connect to a load with

voltage that is independently applied.

• The analog outputs cannot be used to supply power to a 2-wire (loop-

powered) transmitter.

Connect the relays (optional)

W A R N I N G

Potential Electrocution Hazard. Always disconnect power to the

instrument when making electrical connections.

W A R N I N G

Potential Electrocution Hazard. Power and relay terminals are

designed for only single wire termination. Do not use more than one

wire in each terminal.

W A R N I N G

Potential fire hazard. Do not daisy-chain the common relay

connections or jumper wire from the mains power connection inside

the instrument.

C A U T I O N

Fire hazard. Relay loads must be resistive. Always limit current to the

relays with an external fuse or breaker. Obey the relay ratings in the

Specifications section.

The controller contains four electromechanical relays (Relay A, B, C and

D) that are opened or closed by the measured turbidity or diagnostics.

Refer to Configure the relays on page 19. The relay outputs are not

powered.

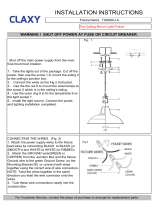

Refer to General wiring procedure on page 10, Figure 8 and Table 3 to

connect the relays to a control or alarm device.

The relay terminals accept 18–12 AWG wire (as determined by load

application). Wire gauge less than 18 AWG is not recommended.

When switching large inductive loads (e.g., motors and pumps) or

currents higher than 5 A, use an auxiliary relay to extend the controller

relay life.

Use the relays at either all high voltage (greater than 30 V-RMS and

42.2 V-PEAK or 60 VDC) or all low voltage (less than 30 V-RMS and

42.2 V-PEAK, or less than 60 VDC). Do not configure a combination of

both high and low voltage.

Figure 8 Typical wiring configuration

1 Relay A 5 Control or alarm device, non-

inductive load switching

2 Relay C 6 Control or alarm device, inductive

load switching

3 Capacitor (0.1 µF, 600 V) 7 100–230 VAC

4 Resistor (100 ohms, 1 watt) 8 Phase 2 or N

Table 3 Relay wiring information

NC COM NO

Normally closed Common Normally open

14 English

Connect the TTL input (optional)

W A R N I N G

Potential Electrocution Hazard. Always disconnect power to the

instrument when making electrical connections.

The controller has one TTL input that lets the user hold or transfer the

analog outputs and the relays. Refer to Figure 5 on page 10. The TTL

input feature function is the same as the output state (HOLD, XFER or

ACTIVE) selected during the last calibration.

• HOLD—The analog outputs and relays are held at their present

values/on-off states.

• XFER (transfer)—The analog output values and relay states are

changed to the selected Set Transfer values/states. Refer to

Configure the analog outputs on page 19 and Configure the relays

on page 19.

• ACTIVE—The analog outputs and relays represent the measured

turbidity. The TTL input is disabled.

To apply a TTL hold or transfer, locally or remotely connect the two TTL

terminals. When this connection is broken, the applied hold or transfer

releases.

Note: The TTL input feature is disabled during calibration and system diagnostic

tests that are started by the user.

Plumbing

Plumb the sensor

D A N G E R

Fire hazard. This product is not designed for use with flammable

liquids.

N O T I C E

When metal fittings are used, do not over tighten them onto the plastic inlet or

outlet fitting of the sensor or damage to the plastic fitting may occur.

Install the sensor in an "in line" process configuration using a closed loop

piping arrangement or in a sample bypass line configuration using an

open drain piping arrangement. Refer to Figure 9 and Figure 10.

Procedure notes:

• Bushings may be used to decrease to a smaller tubing size. Barb or

tube fittings may be installed.

• Use larger sample tubing for applications in which sediment buildup

commonly occurs. A faster flow rate helps flush sediment through the

sensor.

• Use Teflon tape to seal the inlet and outlet connections. Do not use

pipe dope or other liquid sealants.

English 15

Figure 9 Closed-loop piping arrangement

1 Outlet (½–in. NPT female) 6 Process output

2 To open atmosphere (to vent for

calibration)

7 3-way valve (½–in. IPS)

3 Isolation ball valve (½–in. IPS) 8 Inlet (½–in. NPT female)

4 Process output 9 3-way valve (½–in. IPS)

5 Isolation ball valve (½–in. IPS)

Figure 10 Sample bypass line configuration

1 Outlet (½–in. NPT female) 4 Isolation ball valve (½–in. IPS)

2 Isolation ball valve (½–in. IPS) 5 Process input

3 To open drain 6 Inlet (½–in. NPT female)

Connect the sample stream

Install the sample line into a larger process pipe to minimize interference

from air bubbles or pipeline bottom sediment. A sample line that goes

into the center of a process pipe is best.

Figure 11 shows examples of good and bad methods of sample line

installation into a process pipe.

Keep the sample line as short as possible to decrease analysis delay.

Sediment can collect in long sample lines.

16

English

Figure 11 Sampling methods

1 Air 2 Sample flow

User interface and navigation

User interface

Figure 12 shows the display and keypad of the Model T53 controller.

Table 4 gives the key functions.

Figure 12 Display and keypad

1 Display 2 Keypad

Table 4 Key functions

Key Function

MENU Go to the Main Menu screen and cancel the procedure

to change a setting

ESC Go back one menu level or cancel the procedure to

change a setting

ENTER Confirm a menu selection or confirm changes to a

setting

RIGHT and LEFT

arrows

Toggle between the two Measure screens or change the

cursor position

UP and DOWN

arrows

Select a menu, or change a setting or value

Display description

Figure 13 shows the Measure screen. To go to the Measure screen,

push MENU and then ESC.

English

17

Note: If the keypad is not used within 30 minutes, except during calibration or while

specific controller Test/Maintenance functions are used, the display automatically

goes to the Measure screen.

From the Measure screen, push the RIGHT or LEFT arrow to toggle

between the two Measure screens. The second Measure screen is for

Service use only.

To adjust the display contrast, push and hold ENTER and

simultaneously push the UP or DOWN arrow while the Measure screen

shows.

Figure 13 Measure screen

1 Relay status

1

3 Analog Output 1 value (mA)

3

2 Turbidity reading

2

1

The relays that are energized show. For example, if Relay A and C are

energized, "RELAY: A C" shows. The relay status flashes when a relay

overfeed timer has expired.

2

If the reading is not within the measurement range of the controller, a series of

"+" or "–" shows.

3

Push the DOWN arrow to see the Analog Output 2 value (mA).

Startup

Select the language

Select the display language (default = English).

1. Push MENU and select CONFIGURE>LANGUAGE.

2. Use the UP and DOWN arrows to select the language.

3. Push ENTER.

Start the flow

Start the flow of sample through the flow chamber.

1. Turn the 3-way valve handle of the sensor to the OPERATE position.

2. If the recommended isolation valve is used downstream of the

sensor outlet, open the isolation valve slowly to start the flow.

3. Measure the flow at the outlet. Make sure that the flow is within the

flow range shown in Specifications on page 3.

Operation

Configuration

Configure the sensor

1. Push MENU and select CONFIGURE>SENSOR.

2. Select an option.

Option Description

SELECT

UNITS

Select the measurement units shown—NTU (default), TEF,

FNU or FTU.

SET FILTER Set the amount of time for measurement averaging—0 to

60 seconds (30 seconds = default).

For example, if the value is set to 30 seconds, the turbidity

value shown is updated every 30 seconds and the value is

the average of the turbidity values during the previous

30 seconds.

18 English

Option Description

PULSE

SUPPRESS

Set the pulse suppression feature to on or off. ON—Pulse

suppression is enabled. Pulse suppression prevents

unstable readings caused by external interference (e.g.,

entrained gas bubbles in the sample and electromagnetic

interference). Pulse suppression identifies a pulse change

(reading spike) as a temporary upset and does not show

most of the pulse change. OFF—Pulse suppression is

disabled.

ENTER NOTE Select the alphanumberic text that is shown on the top line

of the Measure screen (default = ACCU4). The text can be

a maximum of 8 characters. The selected digit is in square

brackets. Push the UP or DOWN arrow to change the value

of the selected digit. Push the RIGHT arrow to select the

next digit.

3. Push ENTER to confirm.

Configure the analog outputs

If the analog outputs of the controller are used, configure the analog

outputs. The two analog outputs of the controller represent the

measured turbidity.

1. Push MENU and select CONFIGURE>SET OUTPUT 1 (or 2).

2. Select a configuration option.

Option Description

SET 4mA (or

0mA) VALUE

Select the turbidity value that represents 4 mA (or 0 mA)

on the analog output—0.00 (default) to 100.00.

SET 20mA

VALUE

Select the turbidity value that represents 20 mA on the

analog output—0.00 to 100.00 (default).

Note: If the same turbidity values are set for 0/4 mA and

20 mA, the analog outputs automatically go to and stay at

20 mA.

SET

TRANSFER

Set the transfer value of the analog output—4 (or 0) to

20 mA (default = 20 mA). During calibration, the analog

outputs can be held, transferred or kept active. When

transfer is selected, the analog outputs are held at the

transfer value.

Option Description

SET FILTER Set the amount of time for analog output averaging—

0 (default) to 60 seconds.

For example, if the value is set to 30 seconds, the value of

the analog outputs is updated every 30 seconds and the

value is the average of the analog output values during the

previous 30 seconds.

Note: The analog output filter time setting is added to the

sensor filter time setting which increases the time delay

between measurement updates.

SCALE

0mA/4mA

Set the analog output range of the analog output. 0mA—

0 to 20 mA. 4mA (default)—4 to 20 mA.

3. Push ENTER to confirm.

Configure the relays

If the relay connections of the controller are used, configure the relays.

The four relays of the controller are energized or de-energized (opened

or closed) by the measured turbidity or diagnostics.

1. Push MENU and select CONFIGURE>SET RELAY (A, B, C or D).

2. Select a configuration option.

Option Description

SET

FUNCTION

Set the relay to function as a control, alarm or status relay.

ALARM (default)—a relay with separate high and low

alarm points and deadbands that operates in response to

the measured turbidity. CONTROL—a relay with phasing,

setpoint, deadband and overfeed timer that operates in

response to the measured turbidity. STATUS—a relay that

operates only in response to selected system diagnostic

conditions.

English 19

Option Description

SET

TRANSFER

Set the transfer state of the relay—DE-ENERGIZED

(default) or ENERGIZED. During calibration, the relays

can be held, transferred or kept active. When transfer is

selected, the relays are held at the transfer state.

ACTIVATION This menu changes depending on the selected function of

the relay (alarm relay, control relay or status relay). Refer

to SET FUNCTION.

A table for each relay type follows. Refer to the applicable

table for the configuration options.

Alarm relay

Option Description

LOW ALARM Set the low alarm value—0.00 (default) to 100.00. The

relay is energized when the measured turbidity is lower

than the low alarm value.

HIGH ALARM Setsthe high alarm value—0.00 to 100.00 (default). The

relay is energized when the measured turbidity is higher

than the high alarm value.

LOW

DEADBAND

Set the measured turbidity range in which the relay stays

on after the measured turbidity increases above the low

alarm value—0.00 (default) to 10.00.

HIGH

DEADBAND

Set the measured turbidity range in which the relay stays

on after the measured value decreases below the high

alarm value—0.00 (default) to 10.00.

OFF DELAY Set the delay time for the relay to switch off—0 (default)

to 300 seconds.

ON DELAY Set the delay time for the relay to switch on—0 (default)

to 300 seconds.

Control relay

Option Description

PHASE Set the phase for the relay to high or low. HIGH (default)

—The relay is energized when the measured turbidity is

higher than the setpoint. LOW—The relay is energized

when the measured turbidity is lower than the setpoint.

SET SETPOINT Set the setpoint (measured turbidity) value at which the

relay is energized—0.00 to 100.00 (default).

DEADBAND Set the measured turbidity range in which the relay stays

on—0.00 (default) to 10.00. For a high phase relay, this is

the range after the measured value decreases below the

setpoint. For a low phase relay, this is the range after the

measured value increases above the setpoint.

OVERFEED

TIMER

Set the time to limit how long the relay can stay on—

0.0 (default) to 999.9 minutes. For more details on

overfeed timer operation, refer to Overfeed timer for

control relays on page 20.

OFF DELAY Set the delay time for the relay to switch off—0 (default) to

300 seconds.

ON DELAY Set the delay time for the relay to switch on—0 (default) to

300 seconds.

Status relay

Option Description

SET

STATUS

TYPE

Set the status relay type. ALL (default)—The relay is

energized when there is a "Fail" or a "Chamber Unknown"

condition or a "Chamber Dirty" condition. WARN—The relay is

energized only when there is a "Chamber Dirty" condition.

FAIL—The relay is energized only when there is a "Fail" or a

"Chamber Unknown" system condition. Refer to

Troubleshooting on page 24 for the list of conditions.

3. Push ENTER to confirm.

Overfeed timer for control relays

The overfeed timer setting prevents a condition that keeps the measured

turbidity higher than the setpoint or deadband setting (e.g., damaged

20

English

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

他の言語で

- English: Hach Accu4 User manual

関連論文

その他のドキュメント

-

Extech Instruments MO100 ユーザーマニュアル

-

OTT MF pro Basic ユーザーマニュアル

-

T'nB DCC70PLP データシート

T'nB DCC70PLP データシート

-

Bernard Controls SQ Range Installation & Operation Manual

-

Mettler Toledo 5000TOCi Sensor 取扱説明書

-

CLAXY B8878DU インストールガイド

CLAXY B8878DU インストールガイド

-

CLAXY B3027CU-OB ユーザーマニュアル

CLAXY B3027CU-OB ユーザーマニュアル

-

CLAXY B8878DU ユーザーマニュアル

CLAXY B8878DU ユーザーマニュアル

-

Vaisala MHT410 ユーザーマニュアル

-

GF Ball Valve Type 546 Pro ユーザーマニュアル