BW17

English 8

简体中文15

警告!未经阅读本说明书请勿使用本器具。

FIG. A / 图A

f For house hold use only

Note: The diagrams are for reference, the product may change in appearance

or specifications without notice.

ff 仅供家庭使用

注:图形仅供参考。产品的外观或规格可能会发生变化。如有更改,f

恕不另行通知。

13

8

14

16

15

17

18

21

12

20

2

1

3

4

9

10

11

5

7

6

8

3

4

1 2

5 6

Ø13

87

Nr.

FIG. B / 图B

8

8

8

14

8

11 x 2

11 x 2

OK!

KO!

15

3

3

3

6

OK!

BW17

KO!

6

2

1

2

4

1

5

12

正确!

咔嗒

咔嗒

咔嗒

咔嗒

咔嗒

KO!

不正确!

正确!

不正确!

FIG. B / 图B

1

3 4

6

5

2

1

2

2

3

20” sec

C6

H

1

咔嗒

咔嗒

20秒

1 2 4

5 6

0

I

3

FIG. C / 图C

FIG. D /

图D

4

21

19

19

19

20

20

9

2

FIG. E / 图E

7

6

10 10

4 5

Note: The diagrams are for reference, the product may change in appearance or specifications without notice.

注:f图形仅供参考。产品的外观或规格可能会发生变化。如有更改,恕不另行通知。

L1

S

N

Z1

1~

M

T

S1

NCNOC

VOLT

电压

220 V~

50HZ

220 伏

50赫兹

2 X

2,5MM

2

2 X

2,5平方毫米

S = SWITCH

S = 开关

Z1 = CAPACITOR SUPRESSOR

Z1 = 电容器抑制器

T = THERMAL PROTECTOR

T = 热保护器

M = MOTOR

M = 电机

S1 = PRESSURE SWITCH

S1 = 压力开关

10M MAX

最长f10f米

FIG. F / 图F

8 • ENGLISH

HIGH PRESSURE WASHER

BW17

SPECIFICATIONS

BW17

Power 1700W

Working Flow 5,3 l/min

Max water Flow 7 l/min

Pressure 9 MPa (90 bar)

Maximum Pressure 13 MPa (130 bar)

PSI

1885

T° Input 50 ºC

Maximum Input Pressure 1 MPa

Repulsive Force of the Gun to

the Maximum Pressure

11,9 N

Motor Insulation Class F

Motor Protection IPX5

Sound Level K=3 dB(A):

L

PA

(EN 60704-1) 78,8 dB(A)

L

WA

(EN 60704-1) 93 dB(A)

Unit Vibrations (K=1 m/s

2

) ‹2,5 m/s

2

Weight 6,7 kg

SAVE THESE INSTRUCTIONS

The appliance you have purchased is a technologically

advanced product designed by one of the leading

manufacturers of high pressure pumps. To obtain the best

performance from your unit, read this booklet carefully and

follow the instructions each time you use it. We congratulate

you on your choice and wish you successful operation.

GENERAL SAFETY RULES

SAFETY INSTRUCTIONS

General power tool safety warnings.

Warning! Read all safety warnings and

all instructions. Failure to follow the warnings and

instructions listed below may result in electric shock,

fire and/or serious injury.

Save all warnings and instructions for future reference.

The term in all of the warnings listed below refers to your

mains operated (corded) power tool or battery operated

(cordless) power tool.

1. Safety “Must Nots”

a. Explosion or poisoning hazard. Do not use the

appliance with inammable or toxic liquids, or any

products which are not compatible with the correct

operation of the appliance.

b. Injury hazard. Do not direct the water jet towards

people or animals.

c. Electric shock hazard. Do not direct the water jet

towards the unit itself, electrical parts or towards other

electrical equipment

d. Short circuit hazard. Do not use the appliance

outdoors in case of rain.

e. Injury hazard. This machine is not intended for use

by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience

and knowledge. Children should be supervised to

ensure that they do not play with the appliance.

f. Electric shock hazard. Do not touch the plug and/or

socket with wet hands.

g. Electric shock and short circuit hazard. Do not use

the appliance if the electrical cable is damaged.

h. Explosion hazard. Do not use the appliance if the

high pressure hose is damaged.

i. Accident hazard. Do not jam the trigger in the

operating position.

j. Accident hazard. Check that the data plates are

axed to the appliance, if not, inform your dealer.

Units without plates must not be used as they are

unidentiable and potentially dangerous.

k. Explosion hazard. Do not tamper with or alter the

calibration of the safety valve.

l. Hazardous alteration of operating performance.

Do not alter the original diameter of the spray

head nozzle.

m. Accident hazard. Do not leave the appliance

unattended.

n. Short circuit hazard. Do not move the appliance

by pulling on the electrical cable.

o. Make sure that cars do not drive over the high pressure

hose.

2. Safety “Musts”

a. Short circuit hazard. All electrical conductors must

be protected against the water jet.

b. Electric shock hazard. The appliance must only be

connected to an adequate power supply in compliance

with all applicable regulations.

f Use of a safety residual current circuit-breaker

(R.C.C.B.) will provide additional protection

for the operator (30mA).

c. Injury hazard. The high pressure may cause

materials to bounce of surfaces at speed; therefore

protective clothing and safety goggles, safety boots,

ENGLISH • 9

safety gloves, safety helmets with visors, hearing

protection must be worn.

d. Accidental start-up hazard. Before doing work on

the appliance, remove the plug.

e. Injury hazard. Before pressing the trigger, grip the

gun firmly to counteract the recoil.

f. Contamination hazard. Comply with the requirements

of the local water supply company. According to DIN

1988, the appliance may only be connected to the

mains drinking water supply if a backflow preventer

valve with drain facility is installed in the supply hose.

Water that has flowed through backflow preventers

is considered to be non-potable.

g. Accident hazard. Maintenance and/or repair of

electrical components must be carried out by qualified

and Authorized BLACK+DECKER staff for the warranty

to take effect. If the supply cord is damaged, it must

be replaced by the manufacturer, an Authorized

BLACK+DECKER service centre or an equally qualified

person in order to avoid a hazard. If the supply cord

is replaced by an equally qualified person, but not

Authorized by BLACK+DECKER, the warranty will

lose effect.

h. Injury hazard. Discharge residual pressure before

disconnecting the unit hose.

i. Accident hazard. Before using the appliance, check

every time that the screws are fully tightened and that

there are no broken or worn parts.

j. Explosion and electric shock hazard. Only use

detergents which will not corrode the coating

materials of the high pressure hose/electrical cable.

k. Injury hazard. Ensure that all people or animals keep

a minimum distance of 16yd. (15M) away.

3. Improper use

f Use by unskilled persons or those who have not read

and understood the instructions in the manual is forbidden.

f The equipment is not designed to be used by people

(including children) with physical, sensory or mental

capabilities reduced or no experience or knowledge,

unless they are supervised or instructed in the use by

a person responsible for their safety.

f It will be monitored to ensure that children do not play

with the appliance.

f The introduction of inflammable, explosive and toxic

liquids into the appliance is prohibited.

f Use of the appliance in a potentially inflammable or

explosive atmosphere is forbidden.

f The use of non-original spare parts and any other

spare parts not specifically intended for the model in

question is prohibited.

Warning! All modifications to the appliance are prohibited.

Any modifications made to the appliance shall render the

Declaration of Conformity null and void and relieve the

manufacturer of all liability under civil and criminal law.

Warning! Inadequate extension cords can be dangerous. If

an extension cord is used, it shall be suitable for outdoor use,

and the connection has to be kept dry and off the ground. It is

recommended that this is accomplished by means of a cord

reel which keeps the socket at least 60mm above the ground.

Warning! This machine has been designed for use

with the cleaning agent supplied or recommended by

the manufacturer. The use of other cleaning agents or

chemicals may adversely affect the safety of the machine.

Warning! High pressure jets can be dangerous if

subject to misuse. The jet must not be directed at persons,

live electrical equipment or the machine itself.

Warning! Do not use the machine within range of

persons unless they wear protective clothing.

Warning! Do not direct the jet against yourself or others

in order to clean clothes or foot-wear.

Warning! Risk of explosion – Do not spray flammable liquids.

Warning! High pressure cleaners shall not be used by

children or untrained personnel.

Warning! High pressure hoses, fittings and couplings

are important for the safety of the machine. Use only hoses,

fittings and couplings recommended by the manufacturer.

Warning! To ensure machine safety, use only original spare

parts from the manufacturer or approved by the manufacturer.

Warning! Water that has flowed through backflow

preventers is considered to be nonpotable.

Warning! Do not use the machine if a supply cord or

important parts of the machine are damaged, e.g. safety

devices, high pressure hoses, trigger gun.

Warning! Incorrect fuels shall not be used as they may

prove hazardous.

Warning! Do not use near people except that they use

protective clothing.

Warning! Do not use combustion engine powered

machines indoors unless adequate ventilation is assessed

by national labour authorities.

Warning! Ensure that any exhaust emissions are not in

the vicinity of air intakes.

Warning! For gas or oil-heated machines it is important

to provide adequate ventilation and make sure that the flue

gases are properly discharged.

10 • ENGLISH

4. Service

a. Have your power tool serviced by a qualified

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

5. Electrical safety

Your tool is double insulated; therefore no earth

wire is required. Always check that the main voltage

corresponds to the voltage on the rating plate.

Warning! If the power cord is damaged, it must

be replaced by the manufacturer, authorized

BLACK+DECKER Service Center or an equally

qualified person in order to avoid damage or injury.

If the power cord is replaced by an equally qualified

person, but not authorized by BLACK+DECKER,

the warranty will not be valid.

Warning! Always switch off the mains disconnecting

switch when leaving the machine unattended.

6. Labels on tool

The label on your tool may include the following symbols:

Warning! Safety signs. Comply with the instructions

provided by the safety signs ted to the appliance. Check

that they are present and legible; otherwise, replacements

in the original positions.

TECHNICAL INFORMATION

INTENDED USE

This appliance has been designed for individual use for

the cleaning of vehicles, machines, boats, masonry, etc, to

remove stubborn dirt using clean water and biodegradable

chemical detergents.

Vehicle engines may be washed only if the dirty water is

disposed of as per regulations in force.

f Intake water temperature: See data plate on

the appliance.

f Intake water pressure: Below 10 bar.

f Operating ambient temperature: Above 0 °C.

The machine complies with the IEC.

OPERATOR

The symbol on the front cover identifies the appliance’s

intended operator (professional or non-professional).

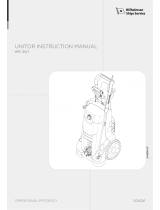

MAIN COMPONENTS (Fig. A)

The machine is delivered partially disassembled

in a carton.

1. Lance

2. Gun with safety catch

3. High pressure hose

4. Nozzle

5. Rotating nozzle

6. Adapter

7. Water filter

8. Brackets

9. Detergent kit

10. Nozzle cleaning tool

11. Screws

12. Electric cable with plug

13. Handle

14. Wheels

15. Lever

16. Hose reel

Caution! Safety devices:

f Starter device (21): The starter device prevents

accidental use of the appliance.

Do not tamper with or adjust the safety valve setting.

f Safety valve and/or pressure limiting valve:

The safety valve is also a pressure limiting valve.

When the gun trigger is released, the valve opens

and the water recirculates through the pump inlet or is

discharged onto the ground.

f Thermostat valve (where fitted):

If the water temperature exceeds the temperature

set by the manufacturer, the thermostat valve

discharges the hot water and draws in an amount of

cold water equal to the amount of water discharged,

until the correct temperature is restored.

f Safety catch (20): Prevents accidental spraying of water

f Overload cutout: stops the appliance in case of overload.

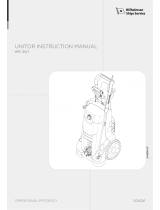

INSTALLATION (Fig. B)

ASSEMBLY

Caution! All installation and assembly operations must

be performed with the appliance disconnected from the

mains power supply.

Read

instructions

manual

Poisoning

hazard

Injury

hazard

Explosion

hazard

Electric shock

and short

circuit hazard

Short circuit

hazard

Danger of

being beaten

by objects that

bounce

Use eye

protection

Wear proper

clothing

...... Class II

Construction

.... Safety Alert

Symbol

V ........ Volts

A ........ Amperes

Hz ....... Hertz

W ........ Watts

min ..... minutes

..... Alternating

Current

Danger sign, warns users not to direct the water jet at people,

animals, elec- trical equipment or the product itself.

Not connect to potable water.

ENGLISH • 11

The assembly sequence is illustrated in Fig. B.

Assembling the rotating nozzle

The rotating nozzle kit delivers greater washing power.

Use of the rotating nozzle may cause of reduction in pressure

of 25% compared to the pressure obtained with the adjustable

nozzle. However, the rotating nozzle kit delivers greater

washing power due to the rotation of the water jet.

Electrical connection

Caution! Check that the electrical supply voltage

and frequency (V/Hz) correspond to those on the

appliance data plate (Fig. B8).

The appliance should only be connected to a mains power

supply equipped with an adequate earth connection and a

differential security breaker (30mA) to cut off the electricity

supply in the instance of a short circuit.

Use of extension cables: Use cables featuring “IPX5”

protection level. The cross-section of the extension cable

should be proportionate to its length; the longer it is, the

greater its cross-section should be.

Water supply connection

Caution! Only clean or filtered water should be used for

intake. The delivery of the water intake tap should be equal

to that of pump capacity. Place the appliance as close to

the water supply system as possible.

Connection points:

Water outlet (OUTLET)

Water inlet with filter (INLET)

Connection to the mains water supply

The appliance can be connected directly to the mains

drinking water supply only if the supply hose is fitted with a

backflow preventer valve as per current regulations in force.

Make sure that the hose is at least Ø 13mm and that it is

reinforced.

Suction of water from open containers

1 Screw the inlet hose with filter to the water INLET and

insert it down to the bottom of the container.

2 Vent the air from the appliance:

a) Unscrew the lance.

b) Start the appliance and keep the gun open until

there are no air bubbles in the water flowing out.

3 Switch the appliance off and screw the lance back on.

N.B.: the maximum suction height is 0.5 m. The suction

hose should be filled before use.

ADJUSTMENT INFORMATION (Fig. C)

f Adjusting the spray nozzle: Water flow is adjusted

by regulating the nozzle (4).

f Adjusting the detergent: To deliver detergent at the

correct pressure, set the nozzle (4) (where fitted) on

“ ” or fit the detergent kit (9) as shown.

f Adjusting the pressur: The regulator is used

to adjust the working pressure. The pressure is shown

on the pressure gauge (where fitted).

USE OF THE APPLIANCE (Fig. D)

CONTROLS

Starter device (21)

Set the starter switch on (ON/I) to:

a) start the motor (in models without TSS device);

b) set the motor ready to start (in models with TSS

device). If there is a pilot light on the starter device, it

should light up. Set the starter device switch on

(OFF/0) to stop the appliance. If there is a pilot light

on the starter device, it should go out.

f Water jet control lever (19).

Warning! - Danger!

During operation the appliance must be positioned as

shown in Fig. D. on a firm, stable surface.

Start-up (Fig D)

1. Turn on the water supply tap fully.

2. Release the safety catch (20).

3. Depress the gun trigger for a few seconds and start up

the appliance using the starter device (ON/I).

Warning! - Danger!

Before starting up the appliance check that it is receiving water

correctly; use of the appliance without water will damage it. Do

not cover the ventilation grilles when the appliance is in use.

TSS models - In TSS models

(with automatic delivery flow cut-off system):

f when the gun trigger is released the dynamic

pressure automatically cuts out the motor;

f when the gun trigger is depressed the automatic

drop in pressure starts the motor and the pressure is

restored after a very slight delay;

f if the TSS is to function correctly, all gun trigger

releasing and depressing operations must be at

least 4-5 seconds apart.

To prevent damage to the appliance, do not allow it to

operate dry and check that it is properly supplied with

water. For models without TSS, to prevent damage to

the appliance due to an increase in water temperature,

do not cut off the jet of water for more than 5 minutes

with the appliance running. Beware of kickback force

when opening the trigger gun.

Stopping the appliance

1. Set the starter device switch on (OFF/0).

2. Depress the gun trigger and discharge the residual

pressure inside the hoses.

12 • ENGLISH

3. Engage the gun safety catch (20).

Restarting

1. Release the safety catch (20).

2. Depress the gun trigger and discharge the residual

air inside the hoses.

3. Set the starter device on (ON/I).

Storage

1. Switch the appliance off (OFF/0).

2. Remove the plug from the socket.

3. Turn off the water supply tap.

4. Discharge the residual pressure from the gun until

all the water has come out of the nozzle.

5. Drain and wash out the detergent tank at the end of

the working session. To wash out the tank, use clean

water instead of the detergent.

6. Engage the gun safety catch (20).

Recommended cleaning procedure

Dissolve dirt by applying the detergent mixed with water to

the surface while still dry.

When dealing with vertical surfaces work from the bottom

upwards. Leave the detergent to act for 1-2 minute but do

not allow the surface to dry. Starting from the bottom, use

the high pressure jet at a minimum distance of 30 cm. Do

not allow the rinse water to run onto unwashed surfaces.

In some cases, scrubbing with brushes is needed to

remove dirt. High pressure is not always the best solution

for good cleaning results, since it may damage some

surfaces. The finest adjustable nozzle jet setting or the

rotating nozzle should not be used on delicate or painted

parts, or on pressurised components (e.g. tyres, inflation

valves, etc.). Effective cleaning depends on both the

pressure and volume of the water used, to the same degree.

MAINTENANCE (Fig. E)

Any maintenance operations not covered by this chapter should

be carried out by an Authorized Sales and Service Centre.

¡Important! To ensure product SAFETY and

RELIABILITY, repairs, maintenance and adjustment

(other than those listed in this manual) should be performed

by authorized service centers or other qualified organizations,

always using identical replacement parts. Unit contains no

user service able parts inside.

Caution! Always disconnect the plug from the power

socket before carrying out any work on the appliance.

Cleaning the nozzle

1. Disconnect the lance from the nozzle.

2. Remove any dirt deposits from the nozzle hole using

the tool (10).

Cleaning the filter

Inspect the intake filter (7) and detergent filter (if fitted)

before each use, and clean in accordance with the

instructions if necessary.

Unjamming the motor (On models with this feature)

In case of lengthy stoppages, limescale sediments may

cause the motor to seize. To unjam the motor, turn the

drive shaft with a tool.

End-of-season storage

Treat the appliance with non-corrosive, non-toxic antifreeze

and lubricate the o-rings using the lubricating grease tube

(where supplied) as shown before storing it away for winter.

Put the appliance in a dry place, protected from frost.

PROTECTING THE ENVIRONMENT

Separate collection. This product must not be

disposed of with normal household waste.

Should you find one day that your

BLACK+DECKER product needs replacement,

or if it is of no further use to you, do not dispose

of it with household waste. Make this product

available for separate collection.

Separate collection of used products and

packaging allows materials to be recycled and

used again. Re-use of recycled materials helps

prevent environmental pollution and reduces the

demand for raw materials. Local regulations may

provide for separate collection of electrical products

from the household, at municipal waste sites or by

the retailer when you purchase a new product.

SERVICE INFORMATION

Black + Decker offers a full network of company-owned

and authorized service locations throughtout Asia. All

Black + Decker Service Centers are staffed with trained

personnel to provide customers with efficient and reliable

product service.

Whether you need technical advice, repair, or genuine

factory replacement parts, contact the Black + Decker

location nearest to you.

NOTE

f Black + Decker’s policy is one of continuous

improvement to our products and, as such, we reserve

the right to change product specifications without prior

notice.

f Standard equipment and accessories may vary by

country.

ENGLISH • 13

Problem Possible Causes Solution

Pump does not reach

working pressure

Nozzle worn Replace nozzle

Water filter fouled Clean filter (7) (Fig. E)

Insufficient water supply Turn on water supply tap fully

Air being sucked into system Check tightness of hose fittings

Air in pump

Switch off the appliance and keep depressing

and releasing the gun trigger until the water

comes out in a steady flow. Switch the appliance

back on again.

Adjustable nozzle not positioned correctly Set nozzle (4) (+) setting (Fig. C)

Thermostatic valve tripped

Wait for correct water temperature to be

restored

Water being sucked from an open

container from a height of more than

0.5 m.

Reduce the suction height.

Pump pressure drops during

suddenly use

Water being sucked from an external tank Connect appliance to the mains water supply

Inlet water too hot Reduce temperature

Nozzle clogged Clean nozzle (Fig. E)

Inlet filter (7) fouled Clean filter (7) (Fig. E)

Motor “buzzes” but fails to

start

Power supply voltage too low

Check that the voltage of the mains power supply

line is the same as that on the plate (Fig. B)

Voltage drop due use of extension cable Check characteristics of extension cable

Appliance not used for a long period

of time

Contact your nearest Authorised Service Centre

Problems with TSS device Contact your nearest Authorised Service Centre

Motor fails to start

No electrical power

Check that the plug is firmly in the socket and

that the mains voltage supply is present (*)

Problems with TSS device

Contact your nearest Authorised Service

Centre

Appliance not used for a long period

of time

Using the tool unjam the motor through the hole

at the rear of the appliance (in models with this

feature)

Water leakages

Seals worn

Have the seals replaced at your nearest

Authorised Service Centre

Safety valve tripped and discharging Contact an Authorised Service Centre

Appliance noisy Water too hot Reduce temperature (see technical data)

Oil leakages Seals worn

Contact your nearest Authorised Service

Centre

TSS versions only: appliance

starts even with gun trigger

released

High pressure system or pump circuit

not watertight

Contact your nearest Authorised Service

Centre

TSS versions only: no water

delivery when gun trigger is

depressed (with supply hose

connected)

Nozzle clogged Clean nozzle (Fig. E)

f Product specifications may differ by country.

f Complete product range may not be available in all

countries. Contact your local Black + Decker dealers

for range availability.

14 • ENGLISH

No detergent sucked in

Adjustable nozzle on high pressure

setting

Set nozzle (4) on «

» setting (Fig. C)

Detergent too dense Dilute with water

High pressure hose extension being

used

Fit original hose

Deposits or restriction in detergent

circuit

Flush with clean water and eliminate any

restrictions. If the problem persists, contact an

Authorised Service Centre

Water escapes from thermo-

stat valve

Water temperature inside pump head

has exceeded max. rated value stated

on nameplate

With appliance in operation, do not stop the

water jet for more than 5 minutes at a time

* If the motor starts and does not restart during operation, wait 2-3 minutes before repeating the start-up procedure

(overload cutout has been tripped).

If the problem recurs more than once, contact your nearest Authorized Service Centre.

简体中文•15

高压清洗器

BW17

规格

BW17

功率

1700W

工作流 5.3 升/分钟

最大水流 7 升/分钟

压力 9 兆 帕( 90 巴)

最大压力 13 兆 帕( 130 巴)

PSI

1885

输入温度

50ºC

最大输入压力 1 兆帕

喷枪达到最大压力时的

排斥力

11.9 牛

马达绝缘等级 F 级

马达防护等级

IPX5

噪声等级 K=3 分贝 (A):

L

PA

(EN 60704-1)

78.8 分贝 (A)

L

WA

(EN 60704-1)

93 分贝 (A)

单位振动加速度

(K=1 m/s

2

)

‹2,5 m/s

2

重量 6.7 千克

请妥善保管好这些说明

您购买的产品技术先进,其设计出自一家领先的高

压泵制造商。为达到最佳使用效果,请仔细阅读本

手册,并始终按照说明使用工具。恭喜您选择我们

的 产 品 。祝 您 成 功 操 作 。一般

一般安全规则

安全说明

电动工具一般安全警告。

警告!请仔细阅读所有安全警告和说明。

如 不 遵 守 以 下 任 何 警 告 和 说 明 ,可 能 会 导 致 触 电 、

火灾和/或严重伤害。

保留所有警告和守则以供日后参考。以下所有警告

中的术语是指电源驱动(有线)电动工具,或者电池

驱 动( 无 线 )电 动 工 具 。

1 . 安 全“ 禁 忌 事 项 ”

a. 爆炸或中毒危险。禁止将本设备与易燃或有毒

液体或者与本产品正常运行不兼容的任何产品

一起使用。

b. 受伤危险。不要将水流射向人或动物。

c. 触电危险。禁 止 将 水 流 射 向 装 置 本 身 、电 气 部 件

或其他电气设备。

d. 短路危险。请勿在户外使用本设备,以防淋雨。

e. 受伤危险。本机器不适合体力、感觉或智力不

足,或者缺乏经验及知识的人员(包括小孩)

使用。应看管好儿童,以确保他们不将此设备当

做玩具来玩。

f. 触电危险。禁止湿手触摸插头和/或插座。

g. 触电和短路危险。电源线损坏时,禁止使用本

设备。

h. 爆炸危险。高压软管损坏时,禁止使用本设备。

i. 事故危险。禁止将触发开关卡在操作位置。

j. 事故危险。确认设备贴有铭牌,如果没有,请告

知经销商。不得使用无铭牌的装置,因为它们无

法 识 别 ,并 且 可 能 存 在 危 险 。

k. 爆炸危险。禁止摆弄或更改安全阀的校准。

l. 操作性能的危险更改。禁止修改喷嘴的原始

尺寸。

m. 事故危险。不要让设备处于无人值守的状态。

n. 短路危险。不要通过拉动电缆来移动设备。

o. 确保车辆不会轧过高压软管。

p. 警 告!高压喷雾器如果使用不当有时会是危

险的。不准将水流射向人员、带电的电气设备或

器具本身。

2 . 安 全“ 注 意 事 项 ”

a. 短路危险。所有导电物体必须进行防喷水

保护。

b. 触电危险。设备只能连接电力充足的电源,以遵

守所有适用法规。

使用安全漏电断路器 (R.C.C.B.) 能为操作人

员提供额外保护(30 毫安)。

c. 受伤危险。高压可能会导致材料从表面高速弹

回,因此必须穿戴防护服和防护眼罩、防护靴、

防护手套、带面甲的防护头盔及听力保护

装置。

d. 意外启动危险。在 对 设 备 作 业 前 ,请 先 拔 下

插头。

e. 受伤危险。在按下扳机前,先紧紧握住喷枪以对

抗反冲力。

f. 污染危险。遵守当地供水公司的要求。按照

DIN1988,只有在供水软管中安装了带有排污设

施的防回流阀时,才能将设备连接到饮用自来

水供水系统。流经防回流阀的水不可饮用。

g. 事故危险。电气组件的维护和/或检修必须由符

合资质且经过授权的 BLACK+DECKER 人员进

行,以便质保生效。如果电源线受损,必须由制

16•简体中文

造商、经过授权的BLACK+DECKER 服务中心或

具有同等资质的人员更换,以免发生危险。如电

源线由具备同等资格但未经 BLACK+DECKER 授

权的人士更换,则产品质保将失效。

h. 受伤危险。在 断 开 装 置 软 管 前 ,先 释 放 剩 余

压力。

i. 事故危险。每次使用设备前,请确保螺丝完全拧

紧 ,而 且 没 有 破 裂 或 磨 损 的 部 件 。

j. 爆炸和触电危险。仅可使用不腐蚀高压软管/电

气线缆涂层材料的洗涤剂。

k. 受伤危险。确保所有人或动物保持至少

16 码(15 米)距离。

3. 不当使用

禁止不熟练的人员或没有阅读和了解手册中说明

的人员使用此设备。

本设备不适合体力、感官或智力不足以及缺乏

经 验 、知 识 的 人 员( 包 括 儿 童 )使 用 ,除 非 负 责

他们安全的人员已经为他们提供关于使用此设

备的监督或指示。

监督儿童,确保他们不将此设备当做玩具

来玩。

禁止将易燃、易爆和有毒液体引入此设备。

禁止在可能发生燃烧或爆炸的环境中使用此

设备。

禁止使用非原装配件或任何其他不是专门用于

相关模型的备件。

警 告!禁止对设备进行任何修改。任何修改都将

导致“符合标准声明”失效,制造商将不承担任何民

事和刑事责任。

警告!不符合规格的延长线会造成危险。使用的

延长线应适合户外使用,连接必须保持干燥且远离

地面。建议通过卷线器来完成此操作,使插座距地面

至少 60 毫米。

警 告!使用不适当延长的软线可能是危险的。

如果使用延长软线,则插头与插座必须是防水结

构的。

警告!本机器设计为使用制造商提供或推荐的清

洁剂。使用其他清洁剂或化学品可能对机器安全产

生不利影响。

警 告!高 压 喷 水 器 使 用 不 当 时 会 很 危 险 。切 勿 将

水流射向人员、带电设备或机器本身。

警告!如果安全范围内有未穿戴防护服的人员,

请勿使用本机器。

警告!不要为了清洗衣服鞋袜而将水流射向自己

或他人。

警告!爆炸危险 – 请勿喷射可燃液体。

警告!儿童或未经培训人员不应使用高压清洁器

及蒸汽清洁器。

警告!高压软管、配件和接头在本机器的安全操

作中发挥重要作用。仅可使用由制造商推荐的软管、

配件和接头。

警 告!高压软管,管接头对器具的安全是重要的, 旧

软管组件不能重复利用。只使用制造厂推荐的软管

与管接头

警告!为了确保器具安全只使用制造厂提供或认可

的配件原物。

警告!流经防回流阀的水不可饮用。

警告!如果器具的电源线或重要部件,例如安

全装置、高压软管、触发喷枪等损坏,不要使用本

器具。

警告!不得使用错误的燃料,因为它们可能会造

成危险。

警 告!禁止在未穿戴防护服的人员附近使用。

警 告!禁止在室内使用内燃机提供动力的机器,

除非国家劳动部评估认为其通风充分。

警 告!确保不在进气口附近排放任何废气。

警 告!对于天然气或汽油加热的机器,务必提供

充分的通风,并确保废气正确排放。

4. 检修

a. 将您的工具交由合格的维修人员检修,只能使

用相同的替换部件进行更换。这样可以确保工具的

安全性。

5. 电气安全

本工具采用双重绝缘,因此无需接地线。

请务必检查电源电压是否与铭牌一致。

警告!如果电源线受损,必须由制造商、

经过授权的

BLACK+DECKER 服务中心或具有同等

资质的人员更换,以免发生损坏或受伤

情况。如电源线由具备同等资格但未经

BLACK+DECKER 授权的人士更换,质保将

无效。

警 告!机器处于无人值守的状态时,务必关闭主

连接开关。进行用户维护之前,请务必切断电源。

简体中文•17

6. 工具上的标签

您的工具上可能包含下列符号:

参阅说明

手册

中毒危险

受伤

危险

爆炸危险

触电和短路

危险

短路危险

被弹回的物

体打中的危

险

使用护目设

备

穿着合适的

服装

.... II 级结构

.... 安全警示

.... 符号

V ......... 伏特

A ......... 安培

Hz ........ 赫兹

W ........ 瓦特

min ...... 分钟

.... 交流电

危 险 标 志 :警 告 用 户 不 得 将 水 流 射 向 人 员 、动 物 、

电气设备或产品本身。

未连接饮用水。

警 告!安 全 标 志。请遵守安装到设备上的安全标志

所提供的说明。请检查以确认安全标志存在并且清

晰易读;否则,请在原位置安装替代品。

技术信息

设计用途

此 设 备 是 专 为 清 洗 车 辆 、机 器 、小 艇 、砖 石 建 筑 等 而

设计,可使用干净的水和可生物降解的化学洗涤剂

去除顽固污垢。

只有按现行法规处理污水时,才可以清洗车辆发

动机。

注入水的温度:查看设备上的铭牌。

注入水的压力:10 巴以下。

工作环境温度:0°C 以上。

机器符合 IEC 要求。

警 告!使用不适当延长的软线可能是危险的。

操作人员

前盖上的符号标识了设备的预期操作人员(专业人

员 或 非 专 业 人 员 )。

主 要 元 件( 图A)

机 器 部 分 拆 装 交 付 ,并 以 纸 箱 包 装 。

1. 喷管

2. 具有安全制动装置的喷枪

3. 高压软管

4. 喷嘴

5. 旋转喷嘴

6. 适配器

7. 水过滤器

8. 支架

9. 洗涤剂套件

10. 喷嘴清洁工具

11. 螺钉

12. 带有插头的电缆

13. 手柄

14. 轮子

15. 杆

16. 软管卷轴

警 示!安 全 装 置:

启动器装置 (21):启动器装置可防止意外启用

设备。

请不要窜改或调整安全阀设置。

安全阀和/或压力限制阀:安全阀也是压力限

制阀。释放喷枪扳机后,阀门将打开,水将重新

循环至水泵入口或排放到地面。

调 温 阀( 如 果 已 安 装 ):

如 果 水 温 超 出 制 造 商 设 定 的 温 度 ,调 温 阀 会 排

除热水,并吸入与排放水量相等的冷水,直至恢

复正确的温度。

安全制动装置 (20): 防止意外喷水

过载切断:过载时停止设备。

安装(图 B)

组装

警示!所有安装和组装操作必须在此设备与主电

源断开连接的情况下执行。

组装顺序如图 B 所示

组装旋转喷嘴

旋转喷嘴套件可提供更强大的清洗能力。

与可调节喷嘴获得的压力相比,使用旋转喷嘴可以

将压力降低 25%。但是,由于旋转喷嘴可产生旋转水

流,因此可提供更强大的清洁能力。

电气连接

警 示!请检查电源电压和频率 (V/Hz) 是否符合设

备铭牌上的电压和频率(图 B8)。

只应将设备连接到装配有适当接地连接的主电源,

且此电源还应装配了差分安全断路器(30 毫安),

以便在设备短路时切断电源。

使用延长电缆:请使用具有“iPX5”保护级别的电

缆。延长电缆的横截面应与电缆长度成正比;电缆

越 长 ,其 横 截 面 应 越 大 。

供水系统连接

警 示!只 应 注 入 干 净 或 经 过 滤 的 水 。入 口 水 龙 头 的

输出量应等于泵容量的输出量。请将设备放置在尽

可能接近供水系统的位置。

18•简体中文

连接点:

出水口 (OUTLET)

带有过滤器的进水口 (INLET)

连接到自来水系统

只有按现行条例

在供水软管上安装了防回流阀后,此设备才可以直

接 连接到饮用自来水系统上。请确保软管的直径至

少为 13 毫米,且该软管经过加固。

从开放容器中吸水

1 用螺丝将带有过滤器的入口软管固定到进水口,

然后将其插入容器底部。

2 从 设 备 通 风 :

a) 拧开喷管螺丝。

b ) 启 动 设 备 并 使 喷 枪 保 持 打 开 状 态 ,直 至 留 出 的

水中没有气泡。

3 关闭设备,然后重新将喷管拧紧。

N.B.:最大吸水高度为 0.5 米。使用前应将吸水软

管注满。

调节信息(图C)

调节喷嘴:通过调节喷嘴 (4) 调节水流。

调节洗涤剂:要以正确的压力提供清洗剂,请将

喷嘴 (4)( 如 果 已 安 装 )设 置 为“ ”,或 者 如 图 所

示安装清洁剂套件 (9)。

调 节 压 力 :使 用 调节器 调节工作压力。压力显示

在 压 力 计 上( 如 果 已 安 装 )。

使用设备(图 D)

控制

启动器装置 (21)

将启动器开关设置为 (ON/I) 以:

a) 启动电机(在不带 TSS 设备的模型中);

b) 设置电机以备启动(在带 TSS 设备的模型中)。

如果启动器装置上有指示灯,则应亮起。将启动器

装置开关设置为(OFF/0) 以 停 止 设 备 。如 果 启 动 器 装

置 上 有 指 示 灯 ,则 应 熄 灭 。

水流控制杆 (19)。

警告!- 危险!

操 作 期 间 ,必 须 按 图 D所示,将设备放置在牢固且平

稳的表面上。

启动(图 D)

1. 完全打开水龙头。

2. 释放安全制动装置 (20)。

3. 压 下 喷 枪 扳 机 几 秒 钟 ,并 使 用

启动器装置 (ON/I) 启动设备。

警告!- 危险!

启动设备前,请检查其是否正常接水;无水使用会使

设 备 受 损 。请 勿在使用设备时盖住通风格栅。

TSS 模型 - 在 TSS 模型

(带有自动输送流切断系统)中:

释放喷枪扳机后,动态压力将自动切断电机;

压下喷枪扳机后,自动压降将启动电机,并在极

短的延 迟后 恢 复压力;

要确保 TSS 能正常工作,所有喷枪扳机释放和

压下操作之间必须间隔至少4-5 秒钟。

为防止设备受损,请禁止干燥运行并确认其适当供

水。对于未配备 TSS 的模型,要防止设备由于水温

升高而受损,请不要在设备运行时截断水流 5 分钟

以上。打开触发器喷枪时,请小心反冲力。

停止设备

1. 将启动器装置开关设置为 (OFF/0)。

2. 压下喷枪扳机,并排出软管内的剩余压力。

3. 啮合安全制动装置 (20)。

重新启动

1. 释放安全制动装置 (20)。

2. 压下喷枪扳机,并排出软管内的剩余空气。

3. 将启动器装置设置为 (ON/I)。

存储

1. 关闭设备 (OFF/0)。

2. 从插座上拔下插头。

3. 关闭水龙头。

4. 排空喷枪内的剩余压力,直至喷嘴中的水全部

流出。

5. 收工时,请排空并清洁洗涤剂箱。要清洁洗涤

剂箱,请使用干净的水,不要使用清洁剂。

6. 啮合安全制动装置 (20)。

推荐的清洁过程

在仍然干燥的表面上涂抹混合有水的洗涤剂以溶

解污垢。

处理垂直表面时,从底部向上进行处理。让清洁剂

作用 1-2 分钟,但不要让表面干燥。从底部开始,在

距离表面至少 30 厘米处利用高压进行喷射。不要

让冲洗水流到未清洗的表面上。

在某些情况下,需要用刷子擦洗来去除污垢。高压

并不一定是获得良好清洁效果的最佳解决方案,因

为它可能会损坏某些表面。不应在精细或涂漆部件

或充压组件(例如,轮胎、充气阀等)上使用最精细

的可调节喷嘴喷射设置或旋转喷嘴。高效的清洁取

决于压力和用水量,两者同样重要。

维 护( 图 E )

本章未涉及的所有维护操作都应由经授权的销售和

服务中心来执行。

简体中文•19

重 要 信 息!为了确保产品安全可靠,所 有 修 理 、

维护和调节工作(除了本手册中列出的以外)都必须

由授权的服务中心或其他合格机构执行,并始终使

用相同的替换部件。本装置内不含可由用户自行检

修的部件。

警 示!对 设 备 执 行 任 何 操 作 之 前 ,务 必 将 插 头 从

电源插座上拔下。

清洁喷嘴

1. 卸下喷嘴的喷管。

2. 使用工具(10) 去除喷嘴孔中的污垢。

清洁过滤器

在每次使用前

检查入口过滤器 (7) 和洗涤剂过滤

器(如果已安装),并根据需要按照说明进行清洁。

排除电机阻塞 (在具有此功能的模型上)

如 果 电 机 长 时 间 停 止 运 行 ,石 灰 石 沉 淀 物 可 能 会 导

致电机堵塞。要排除电机堵塞,请使用工具转动驱

动器轴。

季末存储

要在冬季存储设备,存储前在设备上涂抹非腐蚀且

无毒的防冻剂,并如图所示,使用润滑油管(如果已

提供)润滑 O 形环。将设备放置在干燥场所,注意

防冻。

保护环境

分类回收。本产品不得与普通家庭垃圾一

起处理。

如果您发现您的 BLACK+DECKER 产品需要

进行替换,或您已经不再需要使用这些产

品,请勿将它们与家庭废物一起处理。

请将它们单独分类回收。

分类回收使用过的产品和包装能够让材料

得以再循环和再利用。再生材料的再利用

有 助 于 防 止 环 境 污 染 ,并 降 低 对 原 材 料 的

需求。当地法规可能要求由市政废物处理

点或向您出售新产品的零售商提供将家庭

废物与电气产品分开收集的服务 。

服务信息

Black + Decker 提供覆盖整个亚洲的公司隶属和授

权服务地点。所有 Black + Decker 服务中心都具有

训练有素的人员,为客户提供高效和可靠的产品服

务。

不论您是需要技术建议、维修或原厂替换部件,

请联系离您最近的 Black + Decker 地点。

备注

Black + Decker 的政策之一是持续改进我们

的产品,因此,我们保留随时更改产品规格的

权利,恕不另行通知。

标准设备和附件可能会因国家(地区)而异。

产品规格可能会因为不同的国家(地区)而有

所不同。

并非所有的国家(地区)都可提供完整的产品系

列。有关各产品系列的供货情况,请联系您当地

的 Black + Decker 经销商。

制造商:Annovi Reverberi S.p.A.

地 址:Zona Industriale Torrazzi, Via Martin Luther King

341122 MODENA MO, ITALY

产 地:浙江嘉兴

20•简体中文

问题 可能原因 解决方案

水泵未达到工作压力

喷嘴用旧 更换喷嘴

水过滤器变脏 清洁过滤器 (7)(图 E)

供水不足 将供水系统水龙头完全打开

系统中吸入了空气 检查软管配件的紧密性

泵中有空气

关 闭 设 备 ,然 后 按 下 并 松 开 喷 枪 扳 机 ,

直至水稳定地流出。再次打开设备。

可调喷嘴位置不正确 将喷嘴 (4) 设置为 (+)(图 C)

调温阀跳闸 等待水温恢复正常

水从高度超过 0.5 米的开放容器

中吸入。

降低吸 入高度。

突然使用时泵压降低

水从外部水箱吸入 将设备连接到自来水系统

入口水过热 降低温度

喷嘴阻塞 清洗喷嘴(图 E)

入口过滤器 (7) 污染 清洁过滤器 (7)(图 E)

电 机“ 发 出 声 音 ”,但 未

能启动

电源电压过低

检查电源线上的电压是否与铭牌 (图 B)

上的电压相同

使用延长电缆导致电压降低 检查延长电缆的特性

设备长时间未使用 请与最近的授权服务中心联系

TSS 设备存在问题 请与最近的授权服务中心联系

电机启动失败

未通电

请 检 查 插 头 是 否 在 插 座 中 插 牢 ,电 源 电 压

是否存在 (*)

TSS 设备存在问题 请与最近的授权服务中心联系

设备长时间未使用

使用工具从设备后部的孔排除电机

阻 塞( 在 具 有 此 功 能 的 模 型 中 )

水渗漏

密封件用旧 在最近的授权服务中心更换密封件

安全阀跳闸并放电 请联系授权维修中心

设备有噪音 水太热 降低温度(请参见技术参数)

油渗漏 密封件用旧 请与最近的授权服务中心联系

仅 TSS 版本:设备在释放

喷枪扳机时也会启动

高压系统或泵回路不防水 请与最近的授权服务中心联系

仅 TSS 版本:按下喷枪

扳 机 后 不 出 水( 已 连 接 供

水软管)

喷嘴阻塞 清洗喷嘴(图 E)

未吸入洗涤剂

可调节喷嘴设置为高压

将喷嘴 (4) 设置为 «

» (图 C)

洗涤剂太浓 用水稀释

使用了高压软管延长管 安装原装软管

洗涤剂回路出现沉淀物或阻塞

用清水冲洗,清除堵塞。如果问题仍然存

在 ,请 联 系 授 权 维 修 中 心

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

他の言語で

- English: BLACK+DECKER BW17 User manual

関連論文

-

BLACK+DECKER PW1500S ユーザーマニュアル

-

BLACK+DECKER LSW20 ユーザーマニュアル

-

BLACK+DECKER STPW1600 ユーザーマニュアル

-

BLACK+DECKER PW1370TD ユーザーマニュアル

-

BLACK+DECKER PW1450TD ユーザーマニュアル

-

BLACK+DECKER LST220 ユーザーマニュアル

-

BLACK+DECKER LST136 ユーザーマニュアル

-

BLACK+DECKER LDX116C ユーザーマニュアル

-

BLACK+DECKER STPW1400 ユーザーマニュアル

-

BLACK+DECKER FSMH13151SM ユーザーマニュアル

その他のドキュメント

-

Hitachi AW 130 Handling Instructions Manual

-

Makita HW001G ユーザーマニュアル

-

Stanley STEL670 ユーザーマニュアル

-

Hitachi R 18DA Handling Instructions Manual

-

Creative Aurvana In-Ear2 取扱説明書

-

Unitor HPC 30/1 ユーザーマニュアル

Unitor HPC 30/1 ユーザーマニュアル

-

Pro sKit SS-615 Adjustable Temperature Heat Gun ユーザーマニュアル

Pro sKit SS-615 Adjustable Temperature Heat Gun ユーザーマニュアル

-

Graco Inc. 3Z9329L ユーザーマニュアル

-

VEVOR JY-SA10L ユーザーマニュアル

-

Graco Inc. Xs4 AA ユーザーマニュアル