S and H Serises

Hydraulic Torque Wrench

Operation Manual

Hangzhou WREN Hydraulic Equipment Manufacturing Co.Ltd

Add:No 24 xingxing Road, Xingqiao, Yuhang district, Hangzhou, China

TEL: 0571-88110295 FAX:0571-88110210

PC311100

Http://www.wrenchina.com

W214

The original version of the Chinese Translation

Catalog

Important Receiving Instructions …………………………………1

S Series,Square Drive Torque Wrenches

H Series,LOW Profile Torque Wrenches

Waring And Caution

Operating The Wrench

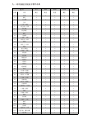

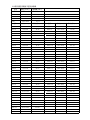

S Series Hydraulic Torque Wrench Pressure-Torque Chart

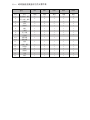

S Series Hydraulic Torque Wrench Pressure-Torque Chart

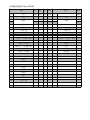

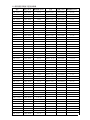

H Series Hydraulic Torque Wrench Pressure-Torque Chart

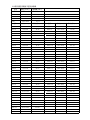

H Series Hydraulic Torque Wrench Pressure-Torque Chart

Inspect、Repair And Maintain

EC Declaration Of Conformity

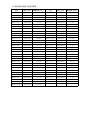

Bolting Tightening Force Recommented Chart

…………………………………1

…………………………………2

…………………………………………2

…………………………4

…………………………………………5

…………9

…………10

…………11

…………12

………………………………………13

……………………………6 8

Operation

………………………………………18

………………………………………14 17

Specification & Parameter

Waring Plate

…………………………………………3

~

~

OPERATION AND MAINTENANCE MANUAL

FOR S AND H HYDRAULIC TORQUE WRENCHES

IMPORTANT RECEIVING INSTRUCTIONS

①

②

③

④

⑤

⑥

⑦

ITEM

BODY

360°SWIVEL J OINT

QUICK COUPLING

FIXING HOOK

360° SWIVEL REACTION ARM

SQUARE DRIVE

DRIVE RETAINER

NAME

SAFTY FIRST !!

Please read carefully follow instructions, warning and caution. Please observe the safety

precautions so that it can avoid personal and equipment to injury when you operate the

equipment. WREN is not responsible for any damage resulting from the operation of

irregularity.

Carefully inspect all components for shipping damage. If any shipping damage is found,

please notify carrier at once. Shipping damage is not covered by warranty. The carrier is

responsible for all repair or replacement cost resulting from damage in shipment.

The material of S series and H series Hydraulic Torque Wrenchs are Aluminium-Titanium

alloy and superhigh strength alloy steel for increased strength, intensity and durability of

the tool. High repeatability, a precise design is with accuracy ±3%.

DESCRIPTION

S series, Square Drive Torque Wrenches:

It is operating manual of S series and H series wrenches, please read carefully follow

instructions﹑warnings and cautions before using the tools.

①

② ③

④

⑤

⑥⑦

1

2

Do not use worn socket and square drive.

WARNING AND CAUTION

WARNING

WARNING

WARNING

CAUTION

CAUTION

WARNING

CAUTION

CAUTION

CAUTION

To avoid personal injury and equipment damages, be sure that every hydraulic component

can rated for 10,000PSI (700kg/cm²) Operating P ressure.

Try to minimum the danger of overl oad Using hydraulic gauge to indicate the working

pressure. Hydraulic gauge is a win dow to show what happened in the hydraulic system.

To replace the worn components with the WREN new components as soon as possible.

Do not subject the components to potential hazard such as fire, sharp surfaces,

extreme

heat or cold, or heave impact.

Never attempt to grasp a leaking pressurized hose with your hands. T he force of escaping

hydraulic fluid could cause serious injury.

Do not let the hose kink, twist, curl or bend so tightly that oil flow within the hose is blocked

or reduced.Do not use the hose to move attach ed equipment. Stress can damage the hose,

causing

personal injury.

To avoid personal injuries and equipment damages, do not remove the shroud of the

wrench.

Do not modify any com ponent of the wrench. Do not change the relief valve which

i

the swivel couplings.s inside

The incorrect system connection w ill cause failure and danger. Before connection, make

sure the swivel couplings being cle an. After application, the swivel couplings must be put

on

the dust caps.

Please use the socket of good perf or mance. The quality should be according with the

standard of ISO-2725 or ISO-1174 or DIN3129 or DIN3121 or ASME-B107.2/1995.

H series, Low Profile Torque Wrenches:

ITEM

NA ME

①

②

③

④

⑤

⑥

⑧

⑦

LOW PROFILE CASSETTE

PIN

POWER HEAD

QUICK COUPL ING

REACTION ARM

LINK PIN

RATCHET

360°×360° SWIVEL J OINT

⑨

360°SWIVEL J OINT

①

② ③ ④

⑤

⑥

⑧

⑦

H27/H54/H120/H210

①

②

③

④

⑨

⑥

⑧

⑦

H430

3

Warning Plate

Warning plate is shown in table 1

IF DRIVE STICKS OUT RIGHT,

IT'S SET FOR TIGHTEN.

LEFT. IT'S SET FOR LOOSE!

LOCK REACTION

ARM BEFORE

USING TOOL!

warning table

Meaning

Affixed Position

IF DRIVE STICKS OUT

RIGHT IT’S SET FOR

TIGHTEN.LEFT IT’S SET

FOR LOOSE!

WORK HEAD

REVERSE LEVER

NO HAND

LOCK REACTION ARM

BEFORE USING TOOL!

REVERSE LEVER

4

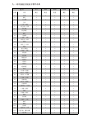

Bo lting

FOR M 1

NOTE:

BOLTING TIGH TENING FORCE RECOMME NTED CH ART

St rengt h Grade

4.8 6.8 8.8 10. 9

Min bre aking

st rength

3 92MPa 588MPa 784MPa 941MP a

Material

Q235(SS41) 35(S35C) 35CrMo(SCM3) 42CrMo(SCM4)

Thread KGM N .m

22 7 69 10 98 14 137 17 165

24 10 98 14 137 21 206 25 247

27 14 137 21 206 29 284 35 341

30 18 176 28 296 41 402 58 569

32 23 225 34 333 55 539 78 765

36 32 314 48 470 70 686 100 981

41 45 441 65 637 105 1029 150 1472

46 60 588 90 882 125 1225 200 1962

50 75 735 115 1127 150 1470 210 2060

55 100 980 150 1470 180 1764 250 2453

60 120 1176 180 1764 220 2156 300 2943

65 155 1519 240 2352 280 2744 390 3826

70 180 1764 280 2744 320 3136 450 4415

75 230 2254 350 3430 400 3920 570 5592

80 280 2744 420 4116 480 4704 670 6573

85 360 3528 530 5149 610 5978 860 8437

90 410 4018 610 5978 790 7742 1100 10791

95 510 4998 760 7448 900 8820

100 580 5684 870 8526 1100 10780

105 660 6468 1000 9800 1290 12642

110 750 7350 1100 10780 1500 14701

115 830 8143 1250 12250 1850 18130

120 900 8820 1400 13720 2250 22050

130 1080 10584 1650 16170 2500 24500

145 1400 13720 2050 20090

155 1670 16366 2550 24990

175 2030 19894 3050 29890

mm

Th e below s are DIN(F or you referen ce)

KGM N .m KGM N .m KGM N .m

The figure of the chart is the Max torque of the bolting, the recommended torque is 80% of chart

figure For instance:M52,strength grade is 8.8,the torque is 4704×80%=3763N.m

12. 9

117 6MPa

40 GrNiMoA(SNCM)

23 225

36 363

49 480

69 680

93 911

120 1176

180 1764

240 2352

250 2450

300 2940

370 3626

470 4606

550 5390

680 6664

850 8330

1050 10290

1350 13230

KGM N .m

14

16

18

20

22

24

27

30

33

36

39

42

45

48

52

56

60

64

68

72

76

80

85

90

100

110

120

M

5

OPERATION

The wrench and power pump are connected by a 700 BAR operating pressure, twin-line hose

assembly. Each end of the hose will have one male and one female connector to assure proper

interconnection between pump and wrench.

CONNECTING THE TOOL

FIG3

S SERIES

DRIVE DIRECTION CHANGE

To remove the square, disengage the drive retainer assembly by depressing the center round

button and gently pulling on the square end of the square drive. The square drive will slide easily

out.

To insert the drive in the tool, place the drive in the desired direction, engage drive and bushing

splines, then twist drive and bushing until ratchet spline can be engaged. Push drive through

ratchet. Depress drive retainer button, engage retainer with drive and release button to lock.

SETTING THE REACTION ARM

All WREN's Torque wrenches are equipped with a universal reaction arm. These reaction arms

are employed to absorb and counteract forces created as the unit operates. The reaction arm

should extend in the same direction of the square drive; However, slight adjustments may be

made to suit your particular application. The function of a reaction device is to hold the tool in

position against the forces generated to tighten or loosen bolts or nuts. Hydraulic wrenches

generate tremendous force. The reaction arm can be

Squ are D rive

Drive Retai ner

Button

FIG4

FIG5

lossing tightening

6

positioned in numerous places within a 3600 circle. However, for the arm to be correctly

positioned, it must be set within a 900 quadrant of that circle. That quadrant is the area

located between the protruding square drive and the bottom of the housing away from the

swivel inlets. It will always be toward the lower half of the housing and on one side of the

housing when tightening and the other side when loosening.

SETTING THE SQUARE DRIVE FOR ROTATION

The position of the square drive when looking toward the shroud will determine if the tool

is set to tighten or loosen the nut. When the square drive extends to the left when looking

at the shroud with the inlets away from you, the tool is set to loosen the nut. When the

square drive extends to the right, the tool is set to tighten the nut. To change the direction

of rotation for MXTA series wrenches simply push the square drive into the housing until

the drive projects out the opposite side of the tool.

SETTING THE TORQUE

After determining the desired torque, use the torque conversion charts on page 5 to

determine the pressure that is necessary to achieve that torque.

1.Connect the tool to the power supply and turn the pump on.

2.Depress the advance remote control button causing the pressure to be shown on the

gauge.

3.Adjust the pressure by first loosing the nut that locks the pressure adjustment handle and

then rotate the handle clockwise to increase the pressure and counter clockwise to

decrease the pressure. When decreasing pressure, always lower the pressure below the

desired point and then bring the pressure gauge back up to the desired pressure.

4.When the desired pressure is reached, retighten the lock nut and cycle the tool again to

confirm that the desired pressure setting has been obtained.

FIG6

T Ha ndle

Lock ing Rin g

1.Place the square Drive in the socket, insert the socket retainer ring and pin, and place the

socket on the nut. Make certain the square drive and socket are the correct size for the nut

and that the socket fully engages the nut.

2.Position the reaction arm against an adjacent nut, flange or solid system

component.Make certain that there is clearance for the hoses and swivel couplings.Do not

allow the tool to react against the hoses, or swivel couplings.When reacting directly off the

tool body with reaction arm removed. Do not react off the exposed end plug spigot.

3.After having turned the pump on and presetting the pressure for the correct

torque,depress the remote control advance button to advance the piston assembly.

4.When the wrench is started, the reaction surface of the wrench or reaction arm will move

against the contact point and the nut will begin to turn. Once the piston reaches the end of

its stroke depress the remote control return button to retract the piston.

OPERATING THE WRENCH

7

5.Continue this cycling operation of advance and retract until the nut is no longer turning

and the pump gauge reaches the preset pressure. The piston rod will retract when the

retract button is pressed and under normal conditions, an audible “Click”will be heard as

the tool resets itself.

6.Continue to cycle the tool until it “Stalls”and the preset psi/torque has been attained.

7.Once the nut stops rotating, cycle the tool one last time to achieve total torque

H SERIES

CONNECTING THE POWER HEAD WITH THE LOW PROFILE CASSETTE

Both the square drive cartridge link and the low clearance ratcheting link are inserted and

removed from the power head in the same way. The “Hook”described by the link's drive

plates is inserted around the fixed pin of the power head, and the link is swung down to rest

along the base of the power head cylinder. At this point, the link pin holes of the power

head and link will align. Insert the link pin to secure.

Ratchet Link

Power head

Link Pin

FIG7

LOW PROFILE WRENCH POSITIONS

The position of the tool relative to the nut determines whether the action will tighten or

loose the nut. The power stroke of the piston assembly will always turn the ratchet hex to

ward the shroud

FIG8

Tightening Loosening

Drawing of Positions

After determining the desired torque, use torque conversion charts on page 5 to determine

the pressure that is necessary to achieve that torque.

1. Connect the tool to the power supply and turn the pump on.

2. Depress the advance remote control button causing the pressure to be shown on the

gauge.

3. Adjust the pressure by first loosing the nut that locks the pressure adjustment handle and

then rotate the handle clockwise to increase the pressure and counter clockwise to

decrease the pressure. When decreasing pressure,always lower the pressure below the

desired point and then bring the pressure gauge back up to the desired pressure.

4.When the desired pressure is reached, retighten the lock nut and cycle the tool again to

confirm that the desired pressure setting has been obtained.

SETING THE TORQUE

OPERATING THE WRENCH

1.Place the ratchet hex on the nut. Make certain it is the correct size for the nut and

that it fully engages the nut.

2.Position the reaction surface against an adjacent nut, flange or solid system

component. Make certain that there is clearance for the hoses, swivel, and inlets. Do

not allow the tool to react against the hoses, swivels or inlets.

3.After having turned the pump on and presetting the pressure for the correct

torque, depress the remote control advance button to advance the piston assembly.

If the notch in the piston rod did not engage the retract pin in the ratchet engage the

pin automatically during the first advance stroke.

4.When the low profile cassette is connected to the housing and the wrench is

started, the reaction surface of the wrench will move against the contact point and

the nut will begin to turn. Once the piston reaches the end of its stroke depress the

remote control return button to retract the piston.

5.Continue this cycling operation of advance and retract until the nut is no longer

turning and the pump gauge reaches the preset pressure. The piston rod will retract

when the retract button is pressed and under normal conditions, an audible

“Click”will be heard as the tool resets itself.

6.Continue to cycle the tool until it “Stall”and the preset psi/torque has been

attained.

7.Once the nut stops rotating, cycle the tool one last time to achieve torque.

8

9

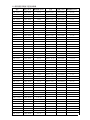

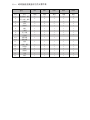

S SERIES HYDRAULIC TORQUE WRENCH PRESSURE-TORQUE CHART

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70 1727

Model Number

Mpa N.m N.m N.m N.m N.m

S17 S45 S100 S150 S370

172

197

221

246

270

295

319

344

369

393

418

442

467

491

516

541

565

590

614

639

663

688

713

737

762

786

811

835

860

885

909

934

958

983

1007

1032

1057

1081

1106

1130

1155

1179

1204

1229

1253

1278

1302

1327

1351

1376

1401

1425

1450

1474

1499

1523

1548

1573

1597

1622

1646

1671

1695

452

517

581

646

710

775

839

904

969

1033

1098

1162

1227

1291

1356

1421

1485

1550

1614

1679

1743

1808

1873

1937

2002

2066

2131

2260

2195

2325

2389

2454

2518

2583

2647

2712

2777

2841

2906

2970

3035

3099

3164

3229

3293

3358

3422

3487

3551

3616

3681

3810

3745

3874

3939

4003

4068

4133

4197

4262

4326

4391

4455

4529

1006

1150

1293

1437

1581

1725

1868

2012

2156

2299

2443

2587

2731

2874

3018

3162

3305

3449

3593

3737

3880

4024

4168

4311

4455

4599

4743

4886

5030

5174

5317

5461

5605

5749

5892

6036

6180

6323

6467

6611

6755

6898

7042

7186

7329

7473

7617

7761

7904

8048

8192

8335

8479

8623

8767

8910

9054

9198

9341

9485

9629

9773

9916

10064

1497

1711

1925

2139

2352

2566

2780

2994

3208

3422

3636

3849

4063

4277

4491

4705

4919

5133

5346

5560

5774

5988

6202

6416

6630

6843

7057

7271

7485

7699

7913

8127

8340

8554

8768

8982

9196

9410

9624

9837

10051

10265

10479

10693

10907

11121

11334

11548

11762

11976

12190

12404

12618

12831

13045

13259

13473

13687

13901

14115

14328

14542

14756

14974

3699

4227

4756

5284

5813

6341

6870

7398

7926

8455

8983

9512

10040

10569

11097

11625

12154

12682

13211

13739

14268

14796

15324

15853

16381

16910

17438

17967

18495

19023

19552

20080

20609

21137

21666

22194

22722

23251

23779

24308

24836

25365

25893

26421

26950

27478

28007

28535

29064

29592

30120

30649

31177

31706

32234

32763

33291

33819

34348

34876

35405

35933

36462

36992

10

Model Number S17 S45 S100 S150 S370

ft.lbsft.lbsft.lbsft.lbs ft.lbspsi

1000

1200

1400

1600

1800

2000

2200

2400

2600

2800

3000

3200

3400

3600

3800

4000

4200

4400

4600

4800

5000

5200

5400

5600

5800

6000

6200

6400

6600

6800

7000

7200

7400

7600

7800

8000

8200

8400

8600

8800

9000

9200

9400

9600

9800

10000

S SERIES HYDRAULIC TORQUE WRENCH PRESSURE-TORQUE CHART

125

150

175

200

226

251

276

301

326

351

376

401

426

451

476

501

526

551

576

601

626

651

677

702

727

752

777

802

827

852

877

902

927

952

977

1002

1027

1052

1077

1102

1128

1153

1178

1203

1228

1253

329

395

461

527

593

658

724

790

856

922

988

1054

1119

1185

1251

1317

1383

1449

1514

1580

1646

1712

1778

1844

1909

1975

2041

2107

2173

2239

2305

2370

2436

2502

2568

2634

2700

2765

2831

2897

2963

3029

3095

3161

3226

3292

733

879

1026

1172

1319

1465

1612

1759

1905

2052

2198

2345

2491

2638

2784

2931

3078

3224

3371

3517

3664

3810

3957

4103

4250

4396

4543

4690

4836

4983

5129

5276

5422

5569

5715

5862

6008

6155

6302

6448

6595

6741

6888

7034

7181

7327

1090

1308

1527

1745

1963

2181

2399

2617

2835

3053

3271

3489

3707

3925

4143

4361

4580

4798

5016

5234

5452

5670

5888

6106

6324

6542

6760

6978

7196

7415

7633

7851

8069

8287

8505

8723

8941

9159

9377

9595

9813

10031

10249

10468

10686

10904

2694

3233

3772

4311

4850

5388

5927

6466

7005

7544

8083

8621

9160

9699

10238

10777

11316

11854

12393

12932

13471

14010

14549

15088

15626

16165

16704

17243

17782

18321

18859

19398

19937

20476

21015

21554

22092

22631

23170

23709

24248

24787

25325

25864

26403

26942

11

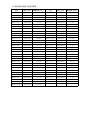

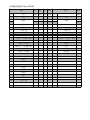

H SERIES HYDRAULIC TORQUE WRENCH PRESSURE-TORQUE CHART

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

Model Number

Mpa N.m N.m N.mN.m N.m N.m N.m N.m N.m N.m

H27 H54 H120 H210 H430

Bolt Size Range

1946 5060 2765 7080 5080 85105 70100 105115 80117 120175

262

299

337

374

412

449

487

524

561

599

636

674

711

749

786

823

861

898

936

973

1011

1048

1085

1123

1160

1198

1235

1273

1310

1347

1385

1422

1460

1497

1535

1572

1609

1647

1684

1722

1759

1797

1834

1871

1909

1946

1984

2021

2059

2096

2133

2171

2208

2246

2283

2321

2358

2395

2433

2470

2508

2545

2583

2625

306

350

393

437

481

525

568

612

656

699

743

787

831

874

918

962

1005

1049

1093

1137

1180

1224

1268

1311

1355

1399

1443

1486

1530

1574

1617

1661

1705

1749

1792

1836

1880

19

23

1967

2011

2055

2098

2142

2186

2229

2273

2317

2361

2404

2448

2492

2535

2579

2623

2667

2710

2754

2798

2841

2885

2929

2973

3016

3068

537

614

690

767

844

921

997

1074

1151

1227

1304

1381

1458

1534

1611

1688

1764

1841

1918

1995

2071

2148

2225

2301

2378

2455

2532

2608

2685

2762

2838

2915

2992

3069

3145

3222

3299

3375

3452

3529

3606

3682

3759

3836

3912

3989

4066

4143

4219

4296

4373

4449

4526

4603

4680

4756

4833

4910

4986

5063

5140

5217

5293

5372

603

689

775

861

948

1034

1120

1206

1292

1378

1464

1551

16

37

1723

1809

1895

1981

2067

2154

2240

2326

2412

2498

2584

2670

2757

2843

2929

3015

3101

3187

3273

3360

3446

3532

3618

3704

3790

3876

3963

4049

4135

4221

4307

4393

4479

4566

4652

4738

4824

4910

4996

5082

5169

5255

5341

5427

5513

5599

5685

5772

5858

5944

6037

1173

1341

1508

1676

1843

2011

2178

2346

2514

2681

2849

3016

3184

3351

3519

3687

3854

4022

4189

4357

4524

4692

4860

5027

5195

5362

5530

5697

5865

6033

6200

6368

6535

6703

6870

7038

7206

7373

7541

7708

7876

8043

8211

8379

8546

8714

8881

9049

9216

9384

9552

9719

9887

10054

10222

10389

10557

10725

10892

11060

11227

11395

11562

11737

1434

1639

1844

2049

2253

2458

2663

2868

3073

3278

3483

3687

3892

4097

4302

4507

4712

4917

5121

5326

5531

5736

5941

6146

6351

6555

6760

6965

7170

7375

7580

7785

7989

8194

8399

8604

8809

9014

9219

9423

9628

9833

10038

10243

10448

10653

10857

11062

11267

11472

11677

11882

12087

12291

12496

12701

12906

13111

13316

13521

13725

13930

14135

14349

2121

2424

2727

3030

3333

3636

3939

4242

4545

4848

5151

5454

5

757

6060

6363

6666

6969

7272

7575

7878

8181

8484

8787

9090

9393

9696

9999

10302

10605

10908

11211

11514

11817

12120

12423

12726

13029

13332

13635

13938

14241

14544

14847

15150

15453

15756

16059

16362

16665

16968

17271

17574

17877

18180

18483

18786

19089

19392

19695

19998

20301

20604

20907

21216

2312

2642

2973

3303

3633

3963

4294

4624

4954

5285

5615

5945

6275

6606

6936

7266

7597

7927

8257

8587

8918

9248

9578

9909

10239

10569

10899

11230

11560

11890

12221

12551

12881

13211

13542

13872

14202

14533

14863

15193

15523

15854

16184

16514

16845

17175

17505

17835

18166

18496

18826

19157

19487

19817

20147

20478

20808

21138

21469

21799

22129

22459

22790

23124

4379

5005

5630

6256

6881

7507

8132

8758

9384

10009

10635

11260

11886

12511

13137

13763

14388

15014

15639

16265

16890

17516

18142

18767

19393

20018

20644

21269

21895

22521

23146

23772

24397

25023

25648

26274

26900

27525

28151

28776

29402

30027

30653

31279

31904

32530

33155

33781

34406

35032

35658

36283

36909

3753

4

38160

38785

39411

40037

40662

41288

41913

42539

43164

43792

4848

5541

6233

6926

7618

8311

9003

9696

10389

11081

11774

12466

13159

13851

14544

15237

15929

16622

17314

18007

18699

19392

20085

20777

21470

22162

22855

23547

24240

24933

25625

26318

27010

27703

28395

29088

29781

30473

31166

31858

32551

33243

33936

34629

35321

36014

36706

37399

38091

38784

39477

40169

40862

41554

42247

42939

43632

44325

45017

45710

46402

47095

47787

48481

H SERIES HYDRAULIC TORQUE WRENCH PRESSURE-TORQUE CHART

Model Number

psi ft.lbs ft.lbs ft.lbs ft.lbs ft.lbs ft.lbs ft.lbs ft.lbs ft.lbs ft.lbs

H27 H54 H120 H210 H430

Bolt Size Range

1946 5060 2765 7080 5080 85105 70100 105115 80117 120175

191

229

267

305

343

382

420

458

496

534

572

611

649

687

725

763

801

840

878

916

954

992

1030

1069

1107

1145

1183

1221

1259

1298

1336

1374

1412

1450

1488

1527

1565

1603

1641

1679

1717

1756

1794

1832

1870

1908

1000

1200

1400

1600

1800

2000

2200

2400

2600

2800

3000

3200

3400

3600

3800

4000

4200

4400

4600

4800

5000

5200

5400

5600

5800

6000

6200

6400

6600

6800

7000

7200

7400

7600

7800

8000

8200

8400

8600

8800

9000

9200

9400

9600

9800

10000

223

267

312

357

401

446

490

535

579

624

669

713

758

802

847

892

936

981

1025

1070

1114

1159

1204

1248

1293

1337

1382

1426

1471

1516

1560

1605

1649

1694

1738

1783

1828

1872

1917

1961

2006

2051

2095

2140

2184

2229

391

469

548

626

704

782

860

939

1017

1095

1173

1252

1330

1408

1

486

1565

1643

1721

1799

1877

1956

2034

2112

2190

2269

2347

2425

2503

2581

2660

2738

2816

2894

2973

3051

3129

3207

3286

3364

3442

3520

3598

3677

3755

3833

3911

439

527

615

703

791

878

966

1054

1142

1230

1318

1405

1493

1581

1669

1757

1845

1933

2020

2108

2196

2284

2372

2460

2547

2635

2723

2811

2899

2987

3074

3162

3250

3338

3426

3514

3601

3689

3777

3865

3953

4041

4129

4216

4304

4392

854

1025

1196

1367

1538

1709

1880

2051

2221

2392

2563

2734

2905

3076

3247

3418

3588

3759

3930

4101

4272

4443

4614

4785

4

955

5126

5297

5468

5639

5810

5981

6152

6322

6493

6664

6835

7006

7177

7348

7519

7689

7860

8031

8202

8373

8544

1044

1253

1462

1671

1880

2089

2298

2507

2716

2925

3133

3342

3551

3760

3969

4178

4387

4596

4805

5014

5222

5431

5640

5849

6058

6267

6476

6685

6894

7102

7311

7520

7729

7938

8147

8356

8565

8774

8983

9191

9400

9609

9818

10027

10236

10445

1545

1854

2163

2472

2781

3090

3399

3708

4017

4326

4635

4944

5253

5562

5871

6180

6488

6797

7106

7415

7724

8033

8342

8651

8960

9269

9578

9887

10196

10505

1081

4

11123

11432

11741

12050

12359

12668

12977

13286

13595

13904

14213

14522

14831

15140

15449

1684

2021

2358

2694

3031

3368

3705

4042

4378

4715

5052

5389

5726

6062

6399

6736

7073

7410

7746

8083

8420

8757

9094

9430

9767

10104

10441

10778

11114

11451

11788

12125

12462

12798

13135

13472

13809

14146

14482

14819

15156

15493

15830

16166

16503

16840

3190

3827

4465

5103

5741

6379

7017

7655

8293

8931

9569

10206

10844

11482

12120

12758

13396

14034

14672

15310

15948

16586

17223

17861

18499

19137

19775

20413

21051

21689

22327

22965

23603

24240

24878

25516

26154

26792

27430

28068

28706

29344

29982

30619

31257

31895

3531

4237

4944

5650

6356

7062

7769

8475

9181

9887

10593

11300

12006

12712

13418

14125

14831

15537

16243

16949

17656

18362

19068

19774

20481

21187

21893

22599

23306

24012

24718

25424

26130

26837

27543

28249

28955

29662

30368

31074

31780

32486

33193

33899

34605

35311

12

Routine Maintenance and transport ofhydraulic torque wrench

Maintenance of the hydraulic torque wrench.

1 Before and after use, should check the screws are loose or not on the torque wrench,

if loose should be tightened. If you do not tighten, it may cause damage to the equipment.

、

2 Inside of the Torque Wrench, all parts should be regularly smear NLGI # 2, in complex

environmental conditions, should be cleaned and lubricated.

、

3 The coupler should be kept clean after work, tighten the dust cap to prevent dust entering

the hydraulic system failure to make the equipment damage.

、

4 Connecting devices, switch direction control valves, check the pressure with or without

exception.

、

5 Check for leakage, if a similar situation, please identify the reasons and processed.、

6 The parts of inside torque wrench are connected, if one part fails, it is bound to affect

other parts caused by wear, so regular inspection and maintenance are very important.

、

Hydraulic torque wrench noise declaration.

Hydraulic torque wrench noise value: 70db.≤

Hydraulic torque wrench transport information.

1 Handle with care.、

2 The shipment should be vertical upward, as shown in the figure 9-1.、

FIG 9-1

3 Product handling, generally using portable, car handling and lifting and moving,、

as shown in the figure 9-2.

FIG 9-2

13

14

15

16

17

S series drawing

NOTE:30# can not part from the piston rod assembly

19

17

16

15

2728

29

30

31

32

33

34

35

34

36

37

38

39

40

41

26

25

24

1

2

15

16

17

18

9

8

7

6

3

4

5

2

20

21

22

23

14

13

12

11

10

S17、S45、S100、S150、S370

series

30# Part drawing

30-4

30-3

30-2

30-1

12

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

ページが読み込まれています...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

関連論文

その他のドキュメント

-

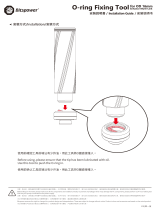

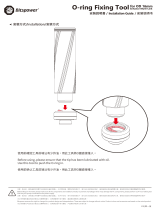

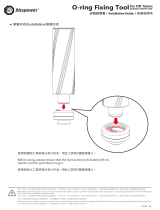

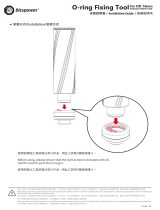

Bitspower BPTA-ORFT16 インストールガイド

Bitspower BPTA-ORFT16 インストールガイド

-

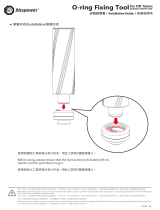

Bitspower BPTA-ORFT12 インストールガイド

Bitspower BPTA-ORFT12 インストールガイド

-

Bitspower BPTA-ORFT14 インストールガイド

Bitspower BPTA-ORFT14 インストールガイド

-

Electrolux EOC5851EAX Recipe book

-

Electrolux EOC5851FAX Recipe book

-

Philips DDL162CHKAC0/93 Product Datasheet

-

Philips DDL162CHKAB0/93 Product Datasheet

-

Philips DDL162CIKAB0/93 Product Datasheet

-

Philips DDL162CIKAB0/93 Product Datasheet

-

Philips HD4681/55 Product Datasheet