5861 SERIES INSTRUCTION MANUAL No. 205-03-300

106-03-004 🄫 2020 KYOCERA Corporation PAGE 9/13

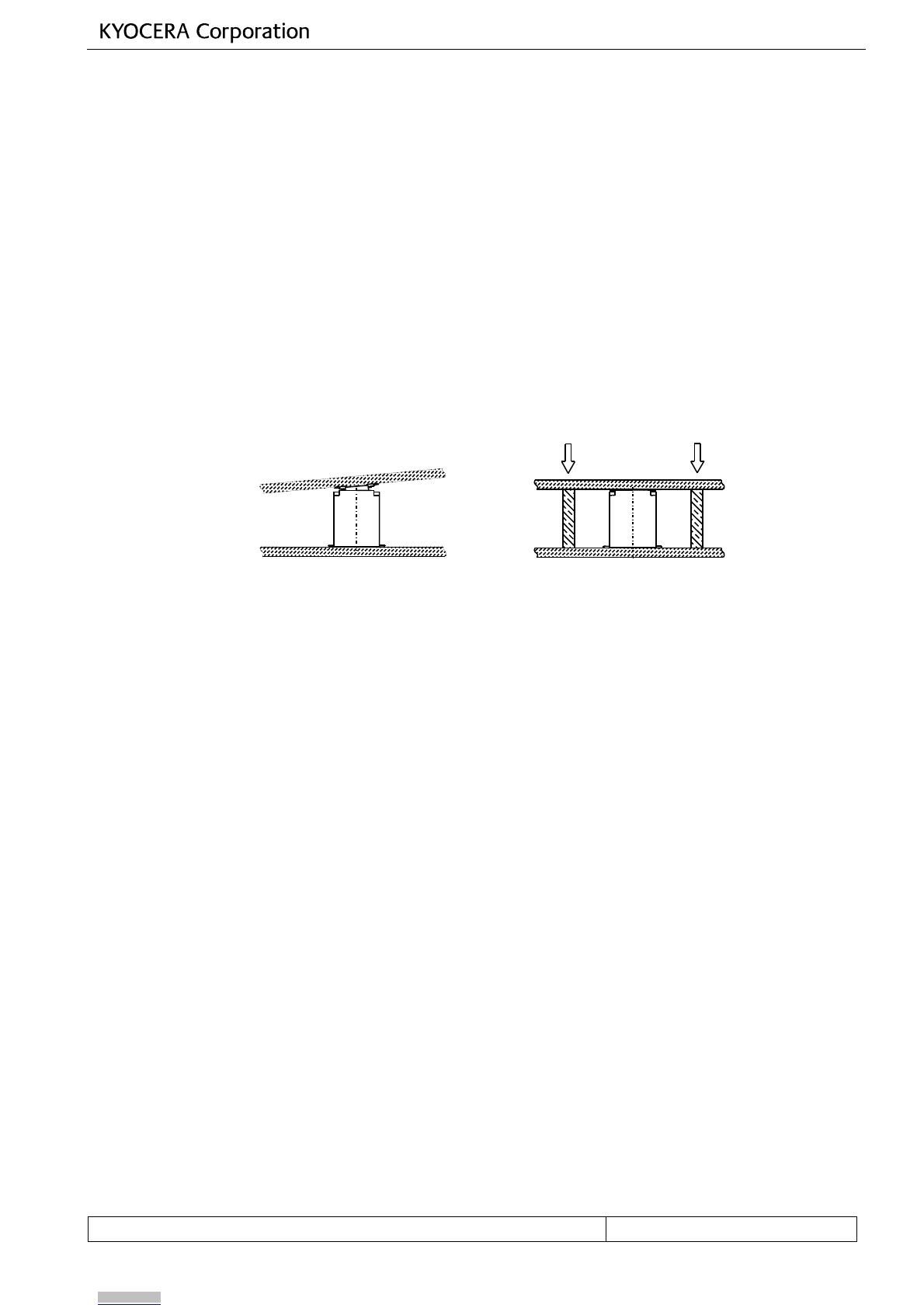

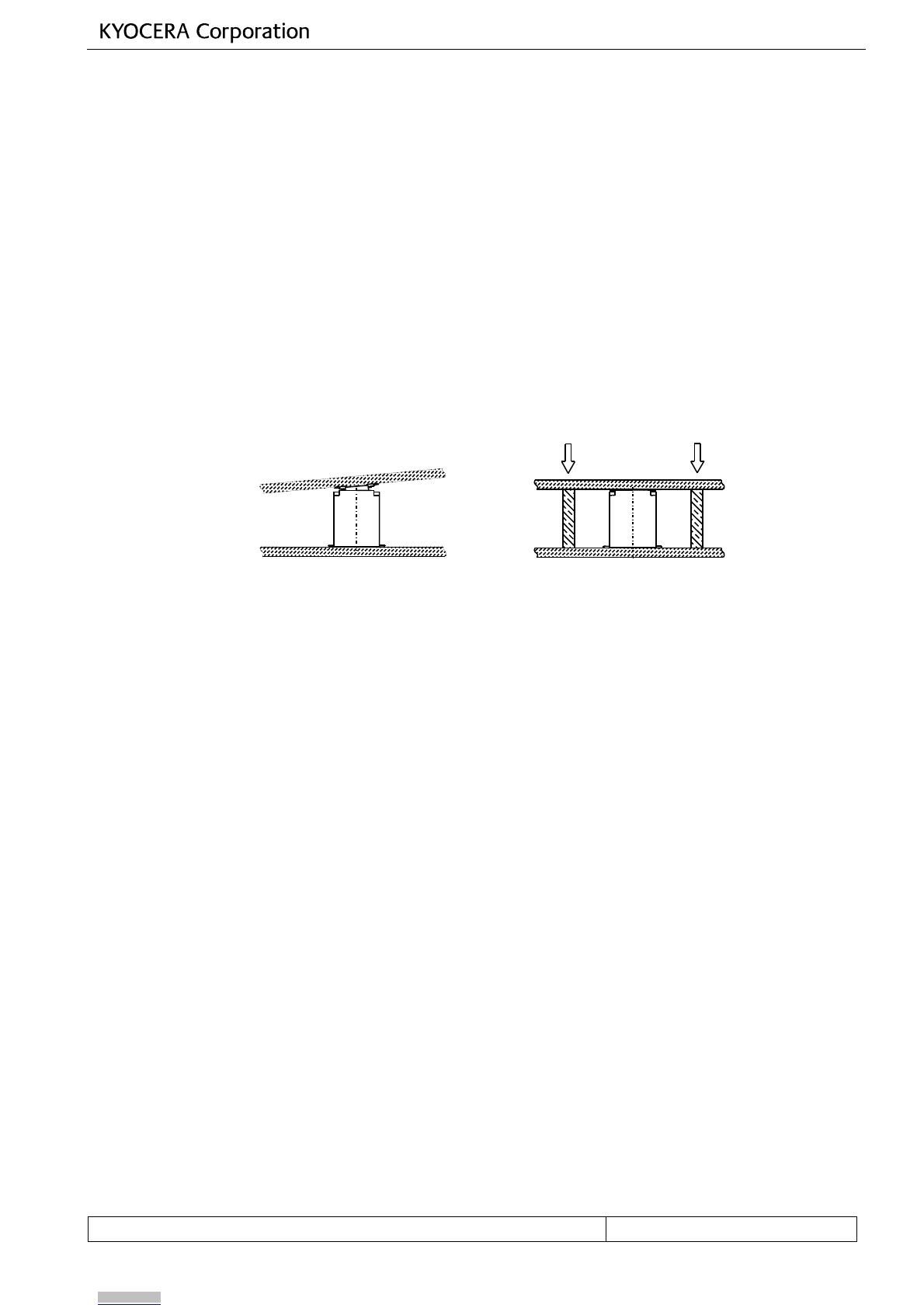

(3) 嵌合は位置合わせを行った上で、Plug 側、Rec.側の両方が平行になる状態で行って下さい。

なお、嵌合位置合わせは、過度な力を加えずに行って下さい。過度な力を加えた場合、成形品の破壊等、

発生する場合があります。

Align connectors before mating, and apply pressure on plug and receptacle connectors so that they would be

mated straight in parallel. Do not apply an excessive pressure when aligning them, or mold goods could be

damaged or broken.

(4) 製品幅が小さいため、嵌合位置合わせは Plug、Rec.が大きくズレないように、ご注意をお願い致します。

Because the connector is very small, be careful not to move the plug or receptacle connector when aligning

them.

(5) 本製品はコネクタのみでの基板保持は出来ません。押さえが無い場合、嵌合のはずれ、

テールはんだ剥離、接触不安定が懸念されます。スペーサーなどをご使用頂き、ねじ止めなどの

嵌合固定が必要です。

The connector is impossible to support the PCB by itself. Without other supporting objects,

imperfect mating , peeling of tails or contacting failure may be caused. As supporting objects,

use spacers fixed by screws.

3-5. チェッカーに関して CHECKER

本製品をそのままチェッカーとしてご使用する場合、耐久性が劣ること、相手側製品に過度にダメージを与え

る場合がありますので、ご注意願います。チェッカーをご要望の際は弊社までご連絡願います。

If the connector targeted in this manual is used as a checker, please be informed that durability

may not be high enough or the product to be checked could be damaged excessively.

Please contact us when you request

our specified

plug or receptacle for the checker.

3-6. 活線挿抜関して HOT SWAP

本製品に電流を流した状態での挿抜は、なさらないよう御願い致します。

Insertion and separation under live current shall not be done.

NG OK

Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.