CDR-HD1500

6

CDR-HD1500

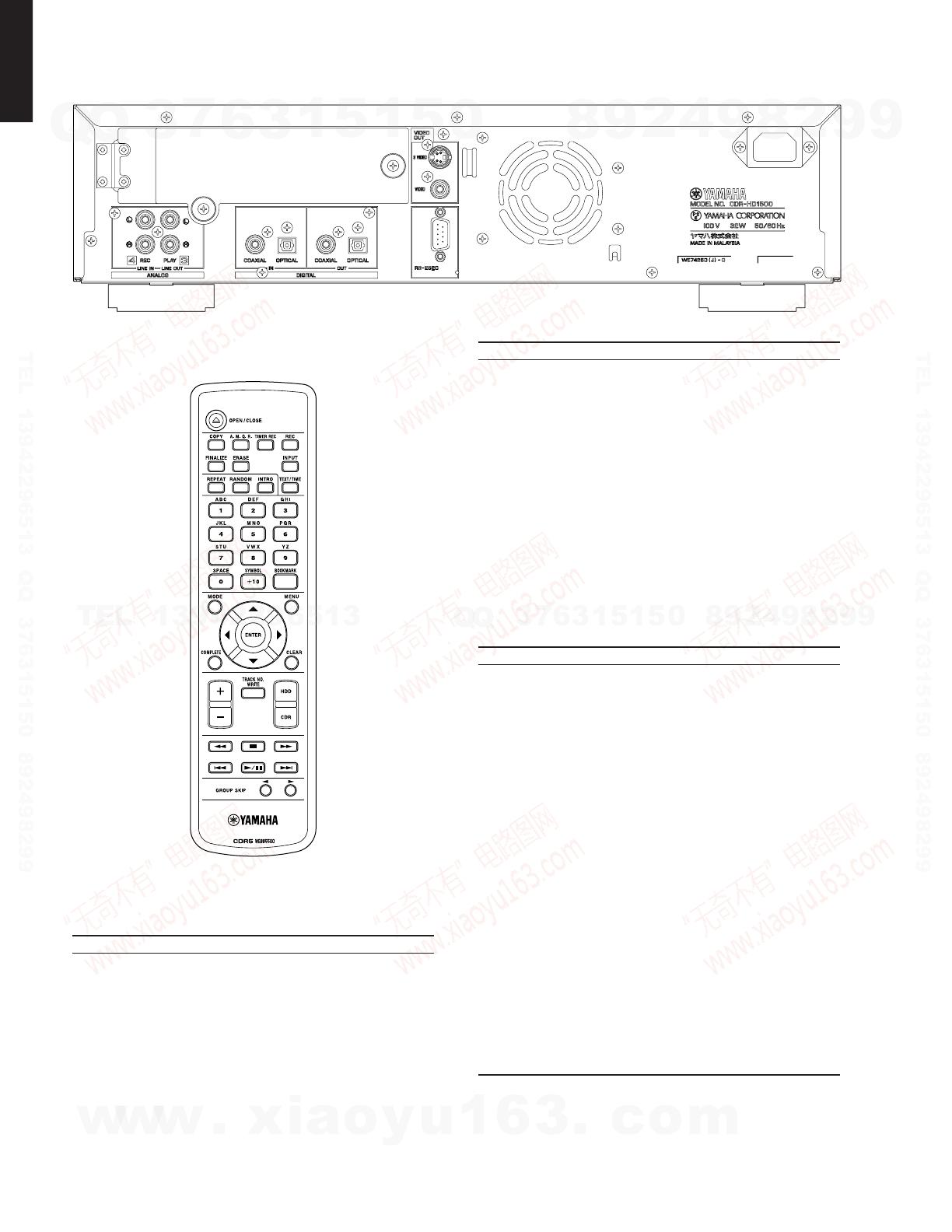

■ REMOTE CONTROL PANEL

CDR-HD1500 (J model)

■ SPECIFICATIONS /

AUDIO PERFORMANCE /

Output Level / (1kHz 0dB) ........................ 2 ± 0.5 Vrms

Frequency Characteristics / (EIAJ)

5Hz to 20kHz.................................................................... ± 0.5 dB

Playback Signal to Noise Ratio / (EIAJ)

...............................................................................105 dB or more

Playback Dynamic Range / (EIAJ)

.................................................................................99 dB or more

Playback THD + Noise / (EIAJ)

...............................................................................0.004 % or less

Recording Signal to Noise Ratio / (EIAJ)

.................................................................................92 dB or more

Recording Dynamic Range / (EIAJ)

.................................................................................92 dB or more

Recording THD + Noise / (EIAJ)

...............................................................................0.006 % or less

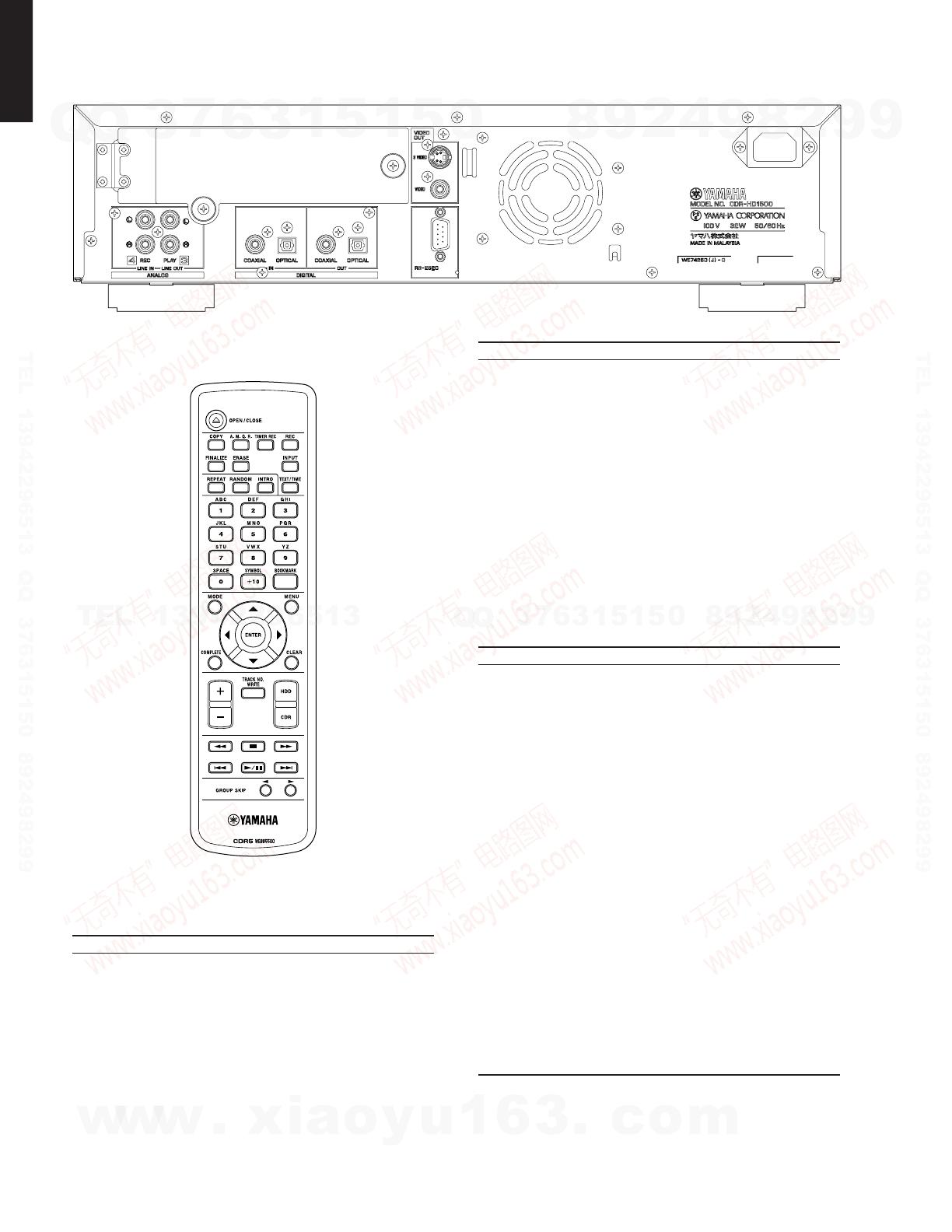

INPUT/OUTPUT /

Line Output /

Output Level ....................................................................... 2 Vrms

Output Resistance ......................................................... 990 ohms

Line Input /

Input Sensitivity ........................................................... 500 mVrms

Input Impedance .......................... 24 k-ohms (REC LEVEL Max.)

Digital Output /

Coaxial Output Level ..................................... 0.5 Vp-p (75 ohms)

Optical Output Level ........................................................ -20 dBm

Sampling Frequency ....................................................... 44.1 kHz

Digital Input /

Coaxial Input Level ........................................ 0.5 Vp-p (75 ohms)

Optical Input Level ........................................................... -20 dBm

Input Gain (with Digital Volume) ........................................ ±12 dB

Input Gain (without Digital Volume) ..................................... ±0 dB

Sampling Frequency Tolerance

........................................... 32 kHz, 44.1 kHz, 48 kHz and 96 kHz

Headphone Output / (Phones Level Max)

Output Level (-20 dB, 150 ohms load) ....................... 330 mVrms

GENERAL /

Model / HDD / CD recorder

Application Discs / CDs, CD-Rs for AUDIO, CD-

RWs for AUDIO

HDD Capacity / No HDD (Support BigDrive over

137GB, up to 400GB)

Power Supply /

U model ................................................................AC 120 V 60 Hz

A model ................................................................AC 240 V 50 Hz

B, G models .........................................................AC 230 V 50 Hz

J model ........................................................... AC 100 V 50/60 Hz

Power Consumption /

U, A, B, G models ................................................................. 37 W

J model .................................................................................. 32 W

Standby Power Consumption / 0 W

Operating Temperature / + 5 °C ~ + 35 °C

Max. Dimensions / (W x H x D)

.................. 435 x 115.5 x 414.5 mm (17-1/8" x 4-1/2" x 16-5/16")

(include legs, terminals and knobs)

Weight /

CDR-HD1500 without HDD ......................... 8.2 kg (18 lbs. 1 oz.)

Panel Color /

Gold Color ......................................................................... J model

Black Color ....................................................... U, A, B, G models

Titanium Color ............................................................ B, G models

Accessories

Remote Control x 1, Optical Cable x 1, Audio Pin Cable x 2,

Video Pin Cable x 1, Power Cable x 1 (U, J models), Batteries

(Manganese Dry) x 2

* Specifications are subject to change without notice due to product

improvements.

U .......... U.S.A. model A ...... Australian model

B .......... British model G ...... European model

J ........... Japanese model

http://www.xiaoyu163.com

http://www.xiaoyu163.com