10 Series 20 Weld Head User’s Manual

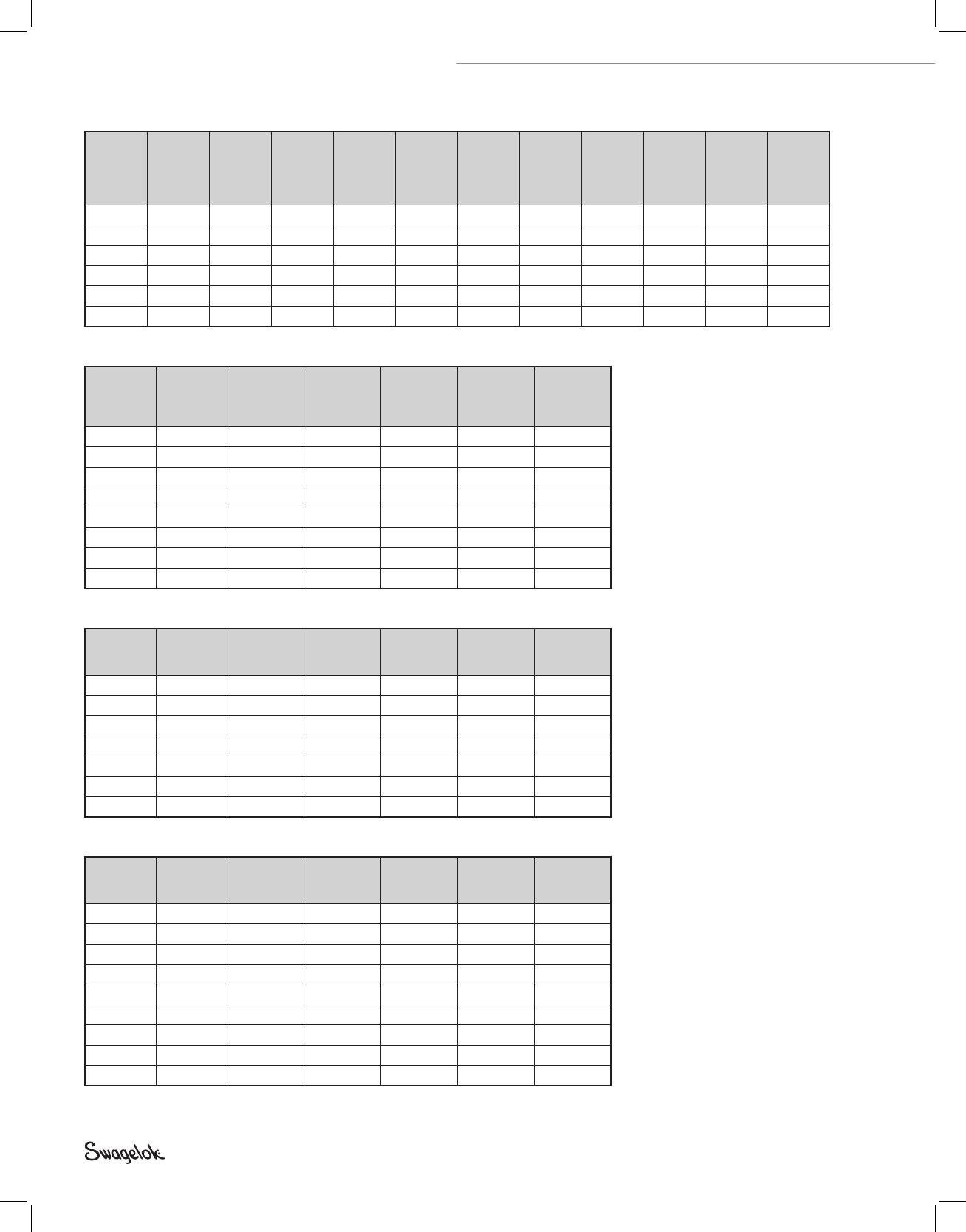

Table 2 SWS-20H Arc Gap Gage Dia. 3.118 in.

Nominal

OD

in.

Actual

OD

in.

Setting

for

0.030in.

Arc Gap

in.

Setting

for

0.040in.

Arc Gap

in.

Setting

for

0.050in.

Arc Gap

in.

Setting

for

0.060in.

Arc Gap

in.

Setting

for

0.070in.

Arc Gap

in.

Setting

for

0,5mm

Arc Gap

mm

Setting

for

0,64mm

Arc Gap

mm

Setting

for

0,76mm

Arc Gap

mm

Setting

for

1,02mm

Arc Gap

mm

Setting

for

1,14mm

Arc Gap

mm

1/2 .500 1.839 1.849 1.859 1.869 1.879 46,45 46,59 46,97 46,97 47,09

3/4 .750 1.964 1.974 1.984 1.994 2.004 49,63 49,77 49,89 50,15 50,27

1 1.000 2.089 2.099 2.109 2.119 2.129 52,80 52,94 53,06 53,32 53,44

1 1/4 1.250 2.214 2.224 2.234 2.244 2.254 55,98 56,12 56,24 56,50 56,62

1 1/2 1.500 2.339 2.349 2.359 2.369 2.379 59,15 59,29 59,41 59,67 59,79

2 2.000 2.589 2.599 2.609 2.619 2.629 65,50 65,64 65,76 66,02 66,14

Table 3 SWS-20H Arc Gap Gage Dia. 79,20 mm.

Nominal

OD

mm

Actual OD

mm

Setting for

0,50 mm

Arc Gap

mm

Setting for

0,64 mm

Arc Gap

mm

Setting for

0,76 mm

Arc Gap

mm

Setting for

1,02 mm

Arc Gap

mm

Setting for

1,14 mm

Arc Gap

mm

12 12,00 46,12 46,26 46,38 46,64 46,76

18 18,00 49,12 49,26 49,38 49,64 49,76

22 22,00 51,12 51,26 51,38 51,64 51,76

23 23,00 51,62 51,76 51,38 51,64 51,76

25 25,00 52,62 52,76 52,88 53,14 53,26

28 28,00 54,12 54,26 54,38 54,64 54,76

35 35,00 57,62 57,76 57,88 58,14 58,26

52 52,00 66,12 66,26 66,38 66,64 66,76

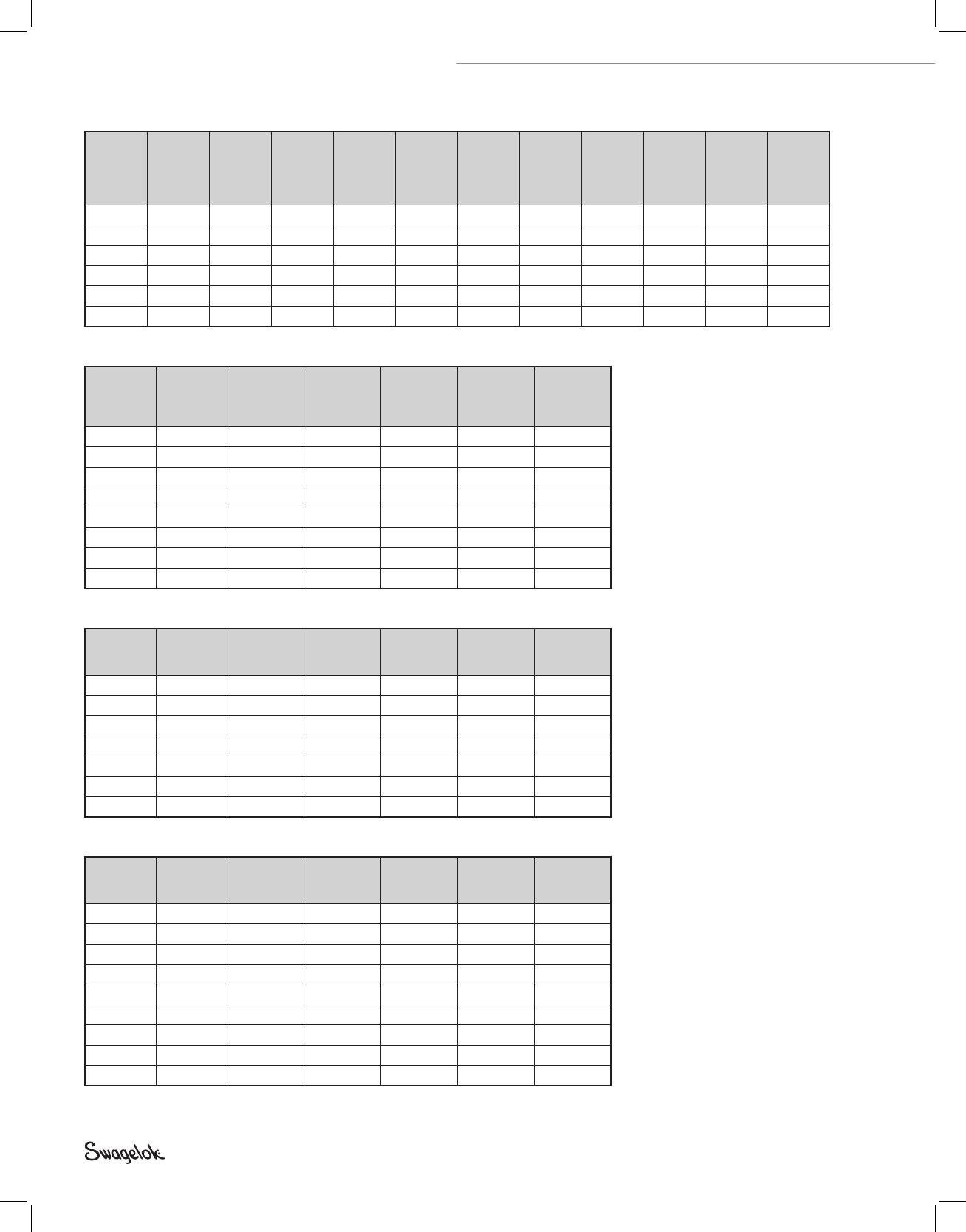

Table 4 SWS-20H Pipe Arc Gap Gage Settings (standard)

Pipe Size

in.

Actual OD

in.

Setting for

0.030 in.

Arc Gap

Setting for

0.040 in.

Arc Gap

Setting for

0.050 in.

Arc Gap

Setting for

0.060 in.

Arc Gap

Setting for

0.070 in.

Arc Gap

1/4 0.54 1.859 1.869 1.879 1.889 1.899

3/8 0.675 1.927 1.937 1.947 1.957 1.967

1/2 0.84 2.009 2.019 2.029 2.039 2.049

3/4 1.05 2.114 2.124 2.134 2.144 2.154

1 1.315 2.247 2.257 2.267 2.277 2.287

1 1/4 1.66 2.419 2.429 2.439 2.449 2.459

1 1/2 1.9 2.539 2.549 2.559 2.569 2.579

Table 5 SWS-20H Pipe Arc Gap Gage Settings (metric)

Pipe Size

mm

Actual OD

mm

Setting for

0,76 mm.

Arc Gap

Setting for

1,02 mm.

Arc Gap

Setting for

1,27 mm.

Arc Gap

Setting for

1,52 mm.

Arc Gap

Setting for

1,78 mm.

Arc Gap

10,2 10,2 45,46 45,72 45,97 46,22 46,48

13,5 13,5 47,11 47,37 47,62 47,87 48,13

17,2 17,2 48,96 49,22 49,47 49,72 49,98

18,9 18,9 49,81 50,07 50,32 50,57 50,83

21,3 21,3 51,01 51,27 51,52 51,77 52,03

26,9 26,9 53,81 54,07 54,32 54,57 54,83

33,7 33,7 57,21 57,47 57,72 57,97 58,23

42,4 42,4 61,56 61,82 62,07 62,32 62,58

48,3 48,3 64,51 64,77 65,02 65,27 65,53

13-205R4.indb 10 2/1/13 2:43 PM