15.After-Sales Service Card

Outbound freight

Company commitment

Company commitment

/

/

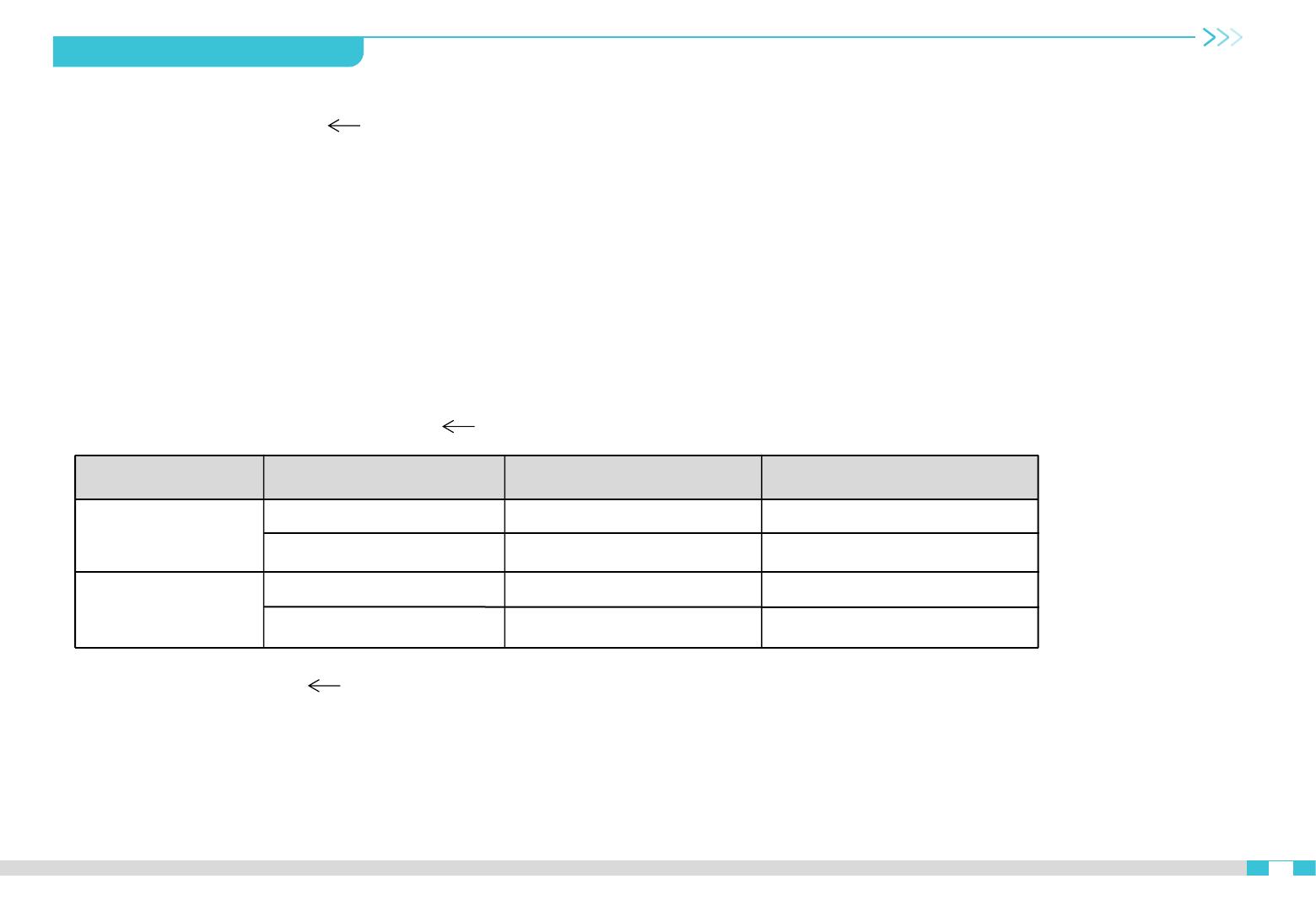

Classification

Non quality problems

Quality problems

Non quality problems

Quality problems

Return freight

Customer commitment

Company commitment

Customer commitment

Company commitment

15

What Is Not Covered?

CREALITY does not guarantee the service as a result of:

1. The proof of purchase being altered or made illegible.

2. The product label or serial number on the product being altered or made

illgible.

3. Normal wear of accessories or consumables for use as release film.

4. Malfunction or damage caused by personal retrofitting or improper

installation and usage.

Return / Exchange Policy

lMeet return / exchange time:

1. The e-commerce platform supports the return of goods without reason within 7 days, that is, the product signing time is 7 days after 168 hours.

2. Due to the quality problem of the machine and non-human damage, you can apply for return and replacement within 15 days after signing.

3. If the goods are purchased through another contract and the time of return and exchange is signed, the contract shall prevail, and the freight standard shall be subject to

the after-sales service card.

lNo damage, scratch, stain, crack, deformation, etc; Random accessories, tools, gifts, packaging, etc. are required to be complete and intact. According to our after-

sales inspection, if the appearance of the product received by return / exchange is damaged, the parts are incomplete or the problem is caused by not packing and mailing

according to the original packaging, the customer shall bear the corresponding expenses, and the specific loss and expenses shall be sent back to the professional after-

sales personnel for inspection and accounting.

lIf the consumables are used, the customer shall bear the cost of the consumables; Because the packing box or packing frame can not be used again after returning to

the factory, the customer should bear the packing fee; The specific loss and cost should be sent back and checked by professional after-sales personnel.

lIf the goods are returned or exchanged due to dislike, want, wrong auction, improper use and dissatisfaction with the product, the customer shall bear the return freight.

lWhen exchanging goods, the customer needs to send the machine back first, and the company will arrange the delivery in time after receiving the machine.

Type

Exchange goods

Return goods

Return / Exchange Freight Standard

5. Malfunction or damage caused by use in non-recommended working environments.

6. Malfunction or damage caused by overuse (overload) or wrong maintenance (damp,

mildew, etc.)

7. Malfunction or damage caused by Force Majeure (fire hazard, earthquake, lightning and

floods, etc.)

8. Malfunction or damage caused by the use of other brand parts or consumable.